2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

As industries across the globe strive for improved energy efficiency and performance, electric motors have emerged as a pivotal technology in this transition. According to the International Energy Agency (IEA), electric motors account for approximately 45% of the total global electricity consumption in industrial applications, highlighting their significant impact on energy use. In the quest for sustainability, innovations in electric motor design and materials are revolutionizing how these systems operate, making them not only more efficient but also capable of delivering enhanced performance.

Expert in the field, Dr. Emily Carter, a leading researcher at the Electric Power Research Institute, emphasizes the importance of these advancements, stating, "The development of next-generation electric motors represents a critical step towards reducing carbon emissions and enhancing operational efficiency across numerous sectors." With the anticipated growth of the electric motors market, projected to reach $175 billion by 2026 according to market analysts, the focus on energy-efficient technologies has never been more crucial. The following discussion explores the top five electric motors set to transform energy efficiency and performance by 2025, shedding light on their innovative features and potential industry impact.

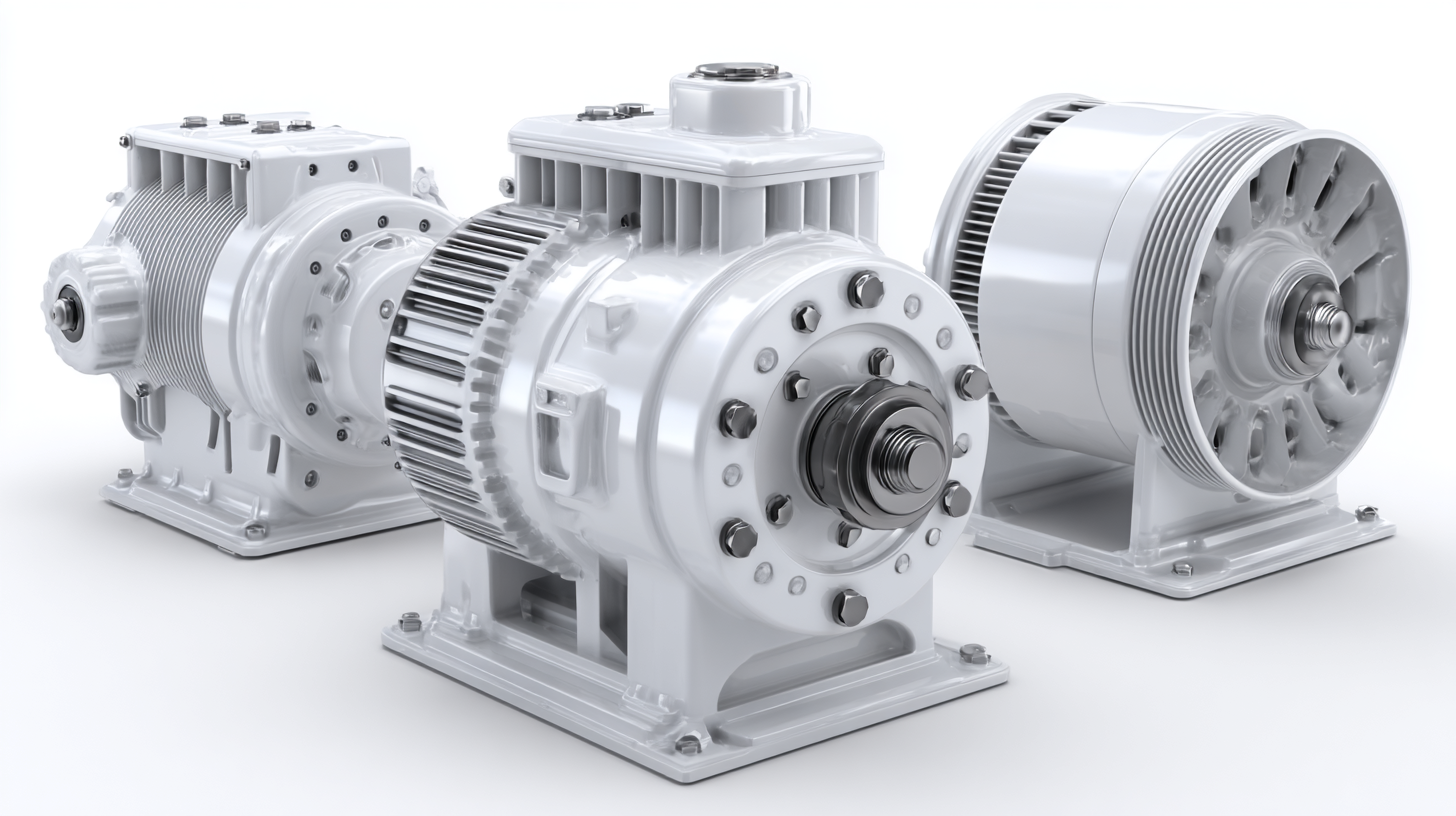

Emerging Electric Motors: Key Technologies Driving Energy Efficiency in 2025

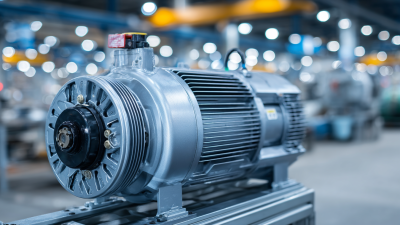

As we move towards 2025, electric motors are set to undergo a significant transformation, driven by innovative technologies that enhance energy efficiency and performance. Key advancements in materials, such as the development of higher-grade magnets and lightweight composites, play a crucial role in reducing energy losses and improving overall efficiency. These materials enable motors to convert electrical energy into mechanical energy more effectively, leading to lower operating costs and environmental impact.

Furthermore, the integration of smart technologies is revolutionizing motor control systems. Advanced algorithms and sensors facilitate real-time monitoring and adaptive performance optimization, enabling electric motors to respond dynamically to varying load conditions. This not only enhances energy efficiency but also prolongs the lifespan of the motors. As manufacturers embrace these emerging technologies in 2025, we can expect electric motors to not only meet but exceed current performance standards, paving the way for a more sustainable future in various industries.

Performance Metrics: How New Electric Motor Designs Achieve Up to 30% Greater Efficiency

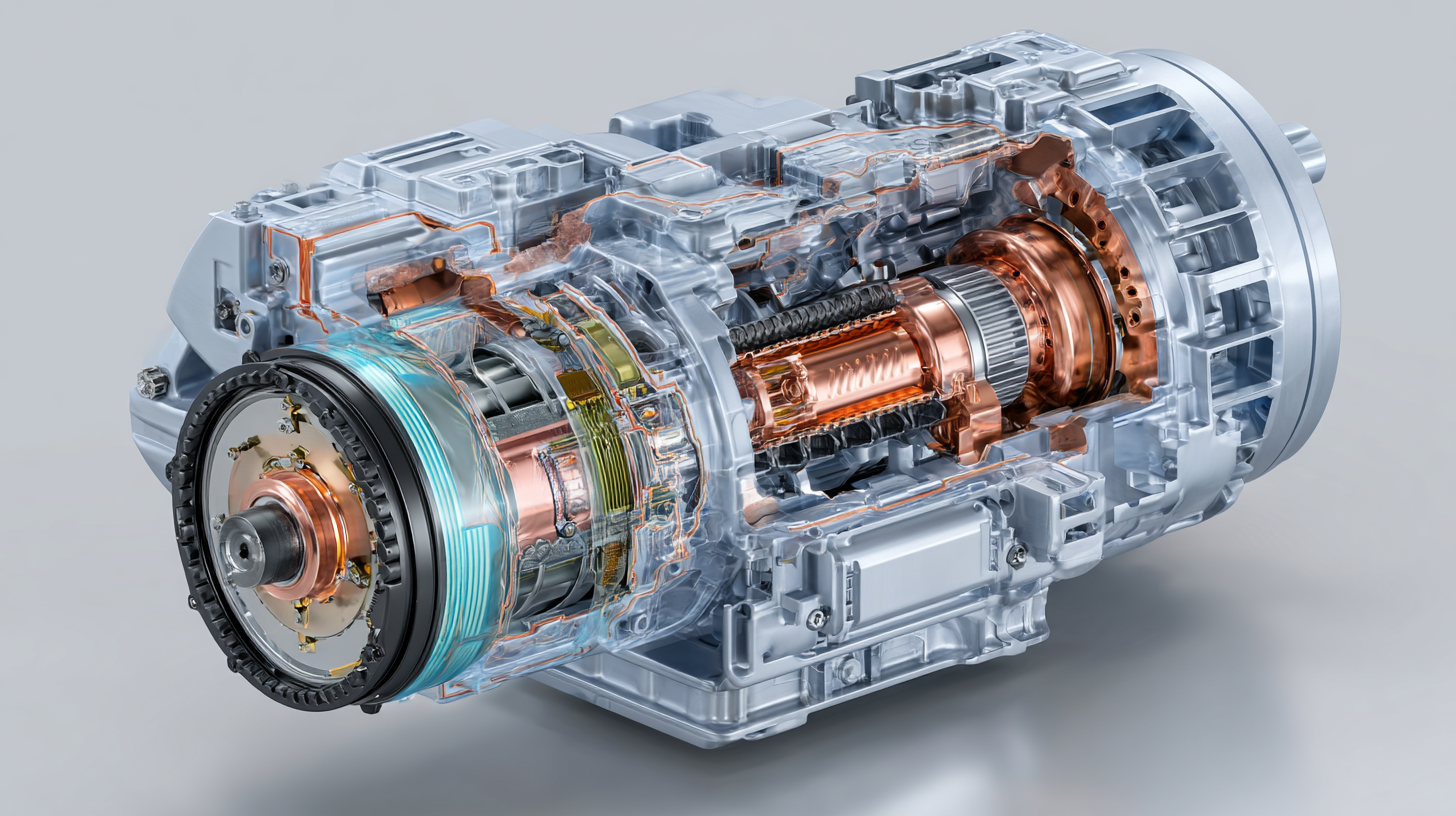

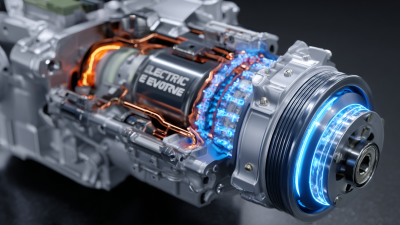

Recent advancements in electric motor technology are revolutionizing energy efficiency and performance, with new designs achieving up to 30% greater efficiency. One significant development involves optimizing the design of Line-Start Permanent Magnet Synchronous Motors (LSPMSM), which have shown promise in enhancing operational performance. The incorporation of innovative sensor technologies that gauge temperature inside these motors also plays a pivotal role in improving efficiency, reducing reliance on rare earth elements in magnets—a critical consideration for electric vehicle applications.

Moreover, a comprehensive analysis of motor designs is leading to better thermal, electrical, and vibration coupling, contributing to a lighter and more efficient structure. These improvements enable electric motors to operate more effectively while minimizing energy loss, showcasing how industry innovations actively address the increasing demand for sustainable and high-performance electric motors. As manufacturers continue to adopt these state-of-the-art strategies, the future of energy-efficient electric drives looks increasingly promising.

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

| Motor Design | Efficiency Improvement (%) | Torque Density (Nm/kg) | Weight (kg) | Applications |

|---|---|---|---|---|

| Design A | 30 | 3.5 | 12 | Electric Vehicles |

| Design B | 25 | 4.0 | 10 | Industrial Machinery |

| Design C | 20 | 3.0 | 15 | Home Appliances |

| Design D | 28 | 4.5 | 11 | Robotic Applications |

| Design E | 30 | 5.0 | 9 | Aerospace |

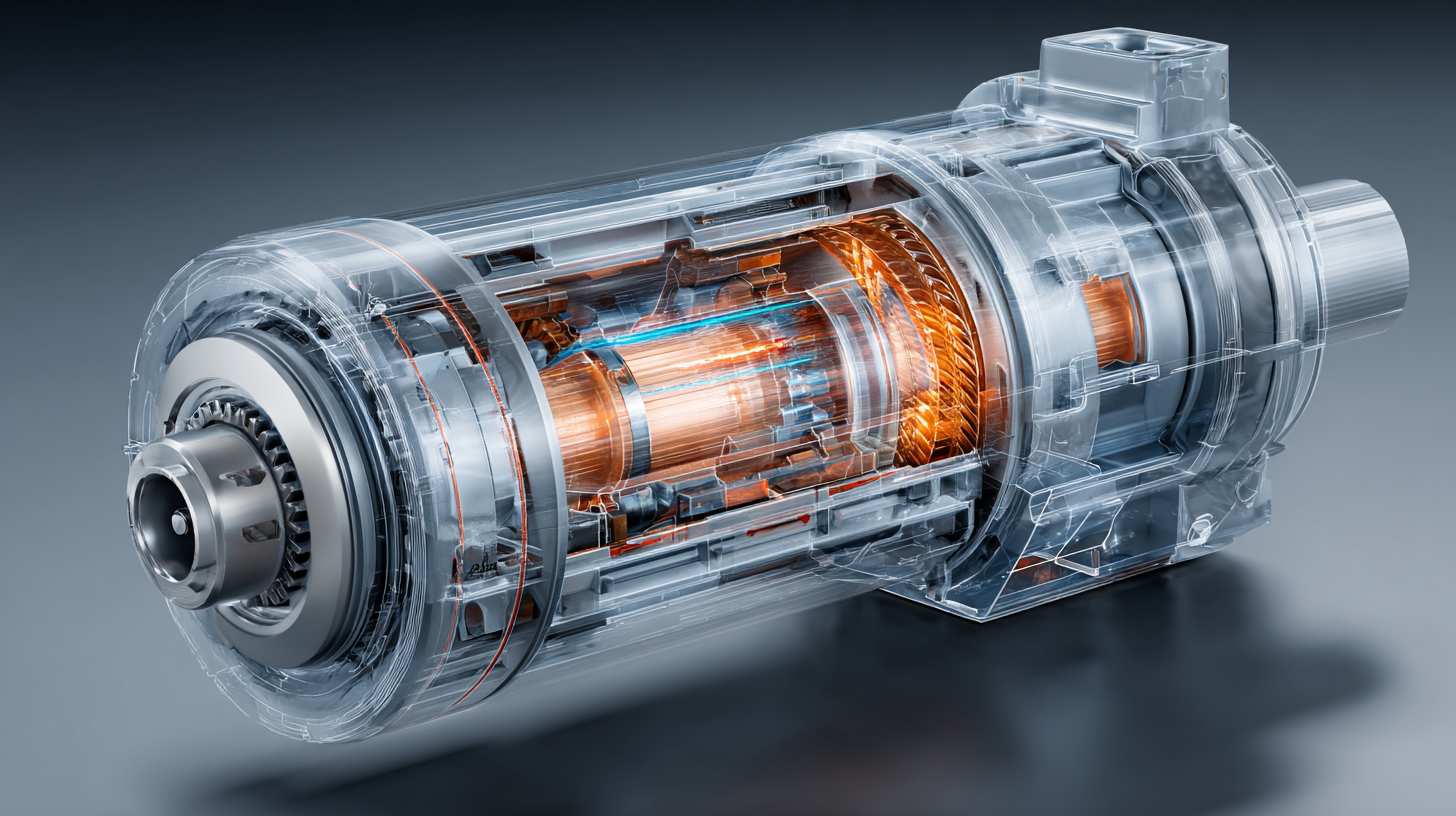

Innovative Materials: The Role of Advanced Composites in Enhancing Motor Durability and Performance

The automotive industry is experiencing a significant shift towards lightweight and high-performance solutions, particularly in the development of electric motors. Innovative materials, including advanced composites, are becoming essential in enhancing motor durability and performance. According to market analysis reports, the use of lightweight materials in automotive applications is anticipated to grow by over 25% in the next five years, driven by both regulatory demands for improved efficiency and consumer preferences for higher performance vehicles.

As electric motors evolve, the incorporation of advanced composites not only reduces weight but also enhances thermal and mechanical stability, which is vital for sustained performance. In a recent report, it was highlighted that vehicles utilizing these materials could see efficiency gains of up to 15%, showcasing the pivotal role of material innovation in the electric vehicle sector.

Tips: When considering the upgrade of electric motors, focus on options that utilize advanced composite materials for better efficiency and durability. Additionally, keep abreast of industry trends as research shows that implementing lighter components directly correlates with improved vehicle performance and lower energy consumption. Always consult the latest data reports to ensure you are making informed decisions tailored to the evolving market landscape.

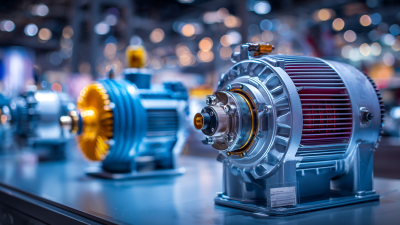

Smart Integration: The Impact of IoT and AI on Electric Motor Performance Optimization

The integration of IoT and AI is fundamentally changing the landscape of electric motors, particularly in the context of energy efficiency and performance optimization. As industries increasingly adopt automation, the demand for high-performance electric motors equipped with smart technologies is surging. These advancements not only enhance operational efficiency but also reduce energy consumption, making them an essential component in modern manufacturing and robotics.

Tips: When considering electric motor solutions, focus on those that incorporate IoT capabilities. This can provide real-time monitoring and data analytics, enabling predictive maintenance and reducing downtime. Additionally, evaluate motors that leverage AI for performance optimization, as they can adapt to varying operational conditions, improving overall efficiency.

The evolving market for electric motors is evident, especially in sectors like robotics, where the projected market size is expected to reach 18.9 billion by 2032, reflecting a steady growth rate. The ingenuity of robotics combined with advanced electric motors will play a critical role in achieving sustainable automation solutions, paving the way for innovations that will define future industrial applications.

Comparative Analysis: Assessing the Top 5 Electric Motors Based on Cost Savings and Longevity Benefits

As the push for energy efficiency intensifies, the automotive industry is witnessing a remarkable shift toward electric motors that not only enhance performance but also provide significant cost savings. This comparative analysis of the top 5 electric motors in 2025 highlights their longevity benefits, demonstrating how investing in advanced technologies can lead to substantial financial rewards over time.

One key advantage of these electric motors is their reduced maintenance needs. Unlike traditional combustion engines, electric motors have fewer moving parts, which minimizes wear and tear. This translates to longer lifespans and fewer replacement costs. For consumers looking to maximize their investment, opting for motors with proven durability can lead to better returns.

**Tip:** When evaluating electric motor options, consider the total cost of ownership, which includes not only the purchase price but also maintenance, efficiency, and potential longevity. Additionally, researching warranty periods can provide insights into the manufacturer's confidence in their motor's lifespan, guiding your purchasing decisions wisely.

Related Posts

-

Exploring Electric Motors Innovations at the 2025 China Import and Export Fair

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Understanding the Role of 3 Phase Electric Motors in Modern Industrial Applications

-

The Future of Electric Motors: Innovations Driving the Next Generation of Sustainable Technology

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications