2026 Top Variable Frequency Motor Controllers What to Know?

Variable frequency motor controllers (VFMCs) play a crucial role in modern industrial applications. As technology advances, their importance continues to grow. According to Dr. Emily Chen, a leading expert in motor control systems, "Efficient control of motors through variable frequency technology is key to sustainability." This perspective highlights the significance of VFMCs in both energy savings and performance optimization.

In industries, VFMCs are used to regulate the speed and torque of electric motors. This control not only enhances efficiency but also reduces energy consumption. For instance, a well-implemented VFMC can cut energy usage by up to 50%. However, challenges do exist in this field. Some manufacturers struggle with integrating new controllers into existing systems. The lack of standardization can lead to compatibility issues, making it crucial to stay informed about the latest technologies.

Understanding the landscape of variable frequency motor controllers in 2026 is essential. New advancements promise better performance and reliability. Yet, as the industry evolves, it is vital to recognize these improvements may not come without setbacks. Continuous learning and adaptation in this rapidly changing environment are imperative for success.

Overview of Variable Frequency Motor Controllers

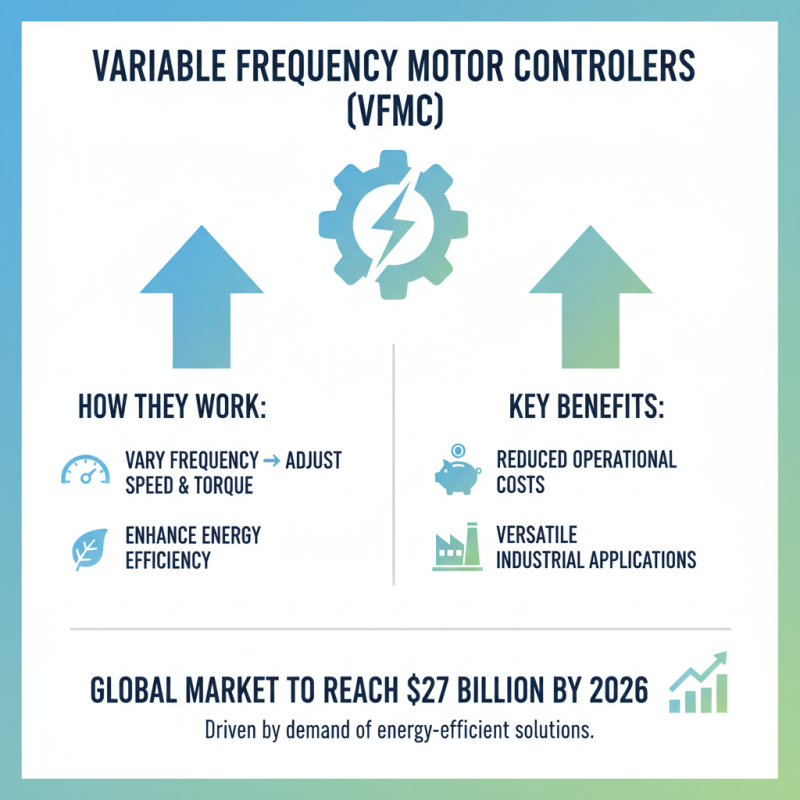

Variable frequency motor controllers (VFMCs) play a crucial role in various industrial applications. They adjust the speed and torque of electric motors by varying the frequency of the supplied voltage. This technology enhances energy efficiency and reduces operational costs. According to a recent industry report, the global market for VFMCs is expected to reach $27 billion by 2026. This growth reflects the rising demand for energy-efficient solutions across multiple sectors.

Understanding VFMCs begins with their function. They optimize electricity usage, leading to lower energy demand. This is key given that about 60% of industrial energy use is attributed to electric motors. Users often overlook maintenance needs, which can lead to efficiency losses over time. Regular checks on performance metrics can mitigate these issues. Without proper upkeep, VFMCs may not achieve their potential efficiency, resulting in excess power consumption.

Additionally, the implementation of VFMCs can present challenges. Knowledge gaps among operators can hinder effective use. The complexity of the technology requires adequate training. Misunderstandings can lead to poor configuration, impacting performance and reliability. Thus, investing in education and awareness is essential. Addressing these hurdles ensures that VFMCs contribute to sustainability efforts in the industry.

Key Features of 2026 Variable Frequency Motor Controllers

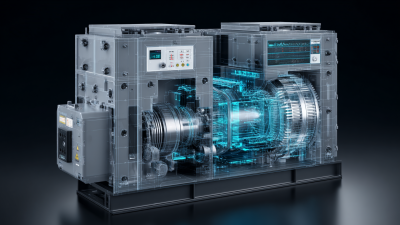

Variable frequency motor controllers (VFMCs) play a crucial role in modern industrial applications. In 2026, the focus is on their key features, which enhance efficiency and performance. One significant feature is the precise speed control offered by these controllers. They help in optimizing power consumption. This aspect is vital for reducing operational costs.

Another important characteristic is the robust design that ensures durability. VFMCs often include advanced cooling systems. These systems help maintain optimal operating temperatures. However, users sometimes overlook the importance of regular maintenance. Neglecting this aspect can lead to performance drops. It's an area that requires attention.

Energy-saving options are also a notable feature. Many VFMCs come with built-in energy monitoring tools. These tools aid users in tracking usage and identifying areas for improvement. Yet, not all users utilize these features effectively. Training and awareness are essential. Improving these can lead to significant savings over time. In 2026, adopting these key features becomes essential for any efficient operation.

Applications and Benefits of Variable Frequency Motor Controllers

Variable Frequency Motor Controllers (VFMCs) play a vital role in numerous applications. They regulate motor speed by adjusting the frequency and voltage supplied to electric motors. This control enhances performance, efficiency, and versatility, making VFMCs invaluable across various industries.

In HVAC systems, VFMCs optimize fan and pump speeds. They adapt to varying load conditions, saving energy. In manufacturing, these controllers ensure precise motor operations, crucial for conveyor belts and assembly lines. This leads to improved production rates. In renewable energy sectors, VFMCs manage variable loads efficiently, making wind and solar energy systems more reliable.

Despite the advantages, challenges exist. Sizing a VFMC for specific applications can be tricky. Oversizing often results in inefficiencies, while undersizing can harm performance. Not all systems are compatible with VFMC integration. It requires careful consideration of the overall system design. Continuous learning and adaptation are essential when incorporating these systems into existing infrastructure.

2026 Top Variable Frequency Motor Controllers

| Model | Power Rating (kW) | Input Voltage (V) | Control Mode | Applications | Efficiency (%)) |

|---|---|---|---|---|---|

| Model A | 5.5 | 380 | V/F Control | Pumps, Fans | 94 |

| Model B | 15 | 400 | Vector Control | Conveyor Systems | 95 |

| Model C | 30 | 480 | Servo Control | CNC Machines | 96 |

| Model D | 7.5 | 230 | Open Loop | HVAC Systems | 93 |

Comparative Analysis of Leading Brands in 2026

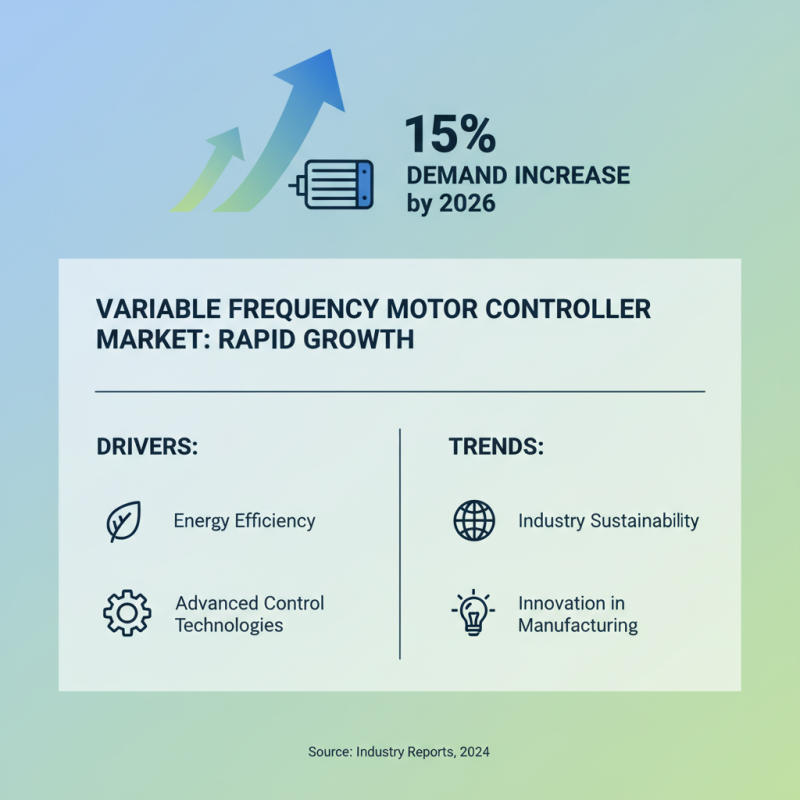

The variable frequency motor controller market is evolving rapidly. Research from industry reports indicates that these controllers are gaining traction. In 2026, the demand is expected to increase by 15% compared to previous years. This growth is driven by energy efficiency and advanced control technologies. Many industries are prioritizing sustainability. This trend pushes manufacturers to invest in innovative solutions.

Comparative analysis of leading brands reveals varied performance metrics. Efficiency ratings fluctuate between 85% and 95% across different models. Some controllers may offer advanced features but lack reliability in harsh conditions. Data from user reviews suggests that ease of integration is a common concern. Not all controllers work seamlessly with existing systems. This can cause operational delays.

Another critical aspect is the cost versus performance ratio. Some controllers may have a low upfront cost, but their long-term maintenance expenses can be higher. Experts warn against selecting a controller solely based on price. A review of warranty terms is essential. Longer warranties can indicate better durability. Many users report dissatisfaction with the support provided; this is a crucial factor often overlooked.

Future Trends in Variable Frequency Motor Controller Technology

The future of variable frequency motor controller technology is evolving rapidly. By 2026, the market is expected to reach a value of over 10 billion USD, according to recent industry reports. This growth is driven by advancements in energy efficiency and automation. Many facilities are looking to reduce energy consumption. Variable frequency drives (VFDs) play a crucial role in this transition.

New innovations, like IoT integration, are enhancing performance. Smart controllers can now provide real-time data analysis. This means operators can monitor and optimize energy usage dynamically. As reported by the Industrial Automation Association, around 40% of energy savings can be achieved through smarter VFD technology. The integration of artificial intelligence is also on the rise. AI can predict maintenance needs, potentially reducing downtime significantly.

Despite these advances, challenges remain. Not all systems are ready to adopt new technologies seamlessly. Compatibility issues with existing infrastructure can cause disruptions. There’s also a learning curve for operators to fully understand new features. As companies strive for efficiency, the path forward must address these growing pains. Investing in training and infrastructure upgrades will be essential for future success.

Related Posts

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions

-

Top Benefits of Variable Frequency Motor Controllers for Efficient Energy Use

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

How to Choose the Right VFD Drive for Your Industrial Application