Top Benefits of Variable Frequency Motor Controllers for Efficient Energy Use

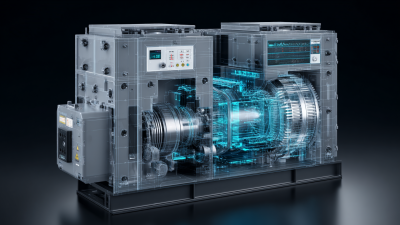

In today's rapidly evolving industrial landscape, the pursuit of energy efficiency has become paramount. One of the most significant advancements in this arena is the adoption of variable frequency motor controllers (VFMCs). These sophisticated devices enable precise control over motor speed and torque by varying the frequency and voltage supplied to electric motors. As industries strive to reduce operational costs and minimize their environmental impact, the integration of VFMCs stands out as a strategic solution that aligns with both economic and ecological goals.

The benefits of implementing variable frequency motor controllers extend far beyond mere energy savings. By optimizing motor performance, these controllers enhance overall system reliability, reduce wear and tear on mechanical components, and contribute to a cleaner operational environment. Additionally, VFMCs empower facilities to adapt to fluctuating demand patterns, thereby improving process efficiency and reducing the need for excess energy consumption during low-demand periods. As organizations increasingly recognize the critical role of energy management, understanding the advantages offered by variable frequency motor controllers becomes essential for achieving sustainable growth and operational excellence.

Benefits of Variable Frequency Motor Controllers in Energy Efficiency

Variable Frequency Motor Controllers (VFMCs) play a crucial role in enhancing energy efficiency in various industrial applications. By allowing motors to operate at variable speeds, these controllers enable precise control over machinery, reducing energy consumption during low-demand periods. Instead of running at a fixed speed irrespective of the load, VFMCs adjust the motor speed according to the operational requirements, which leads to significant energy savings. This adaptability not only diminishes electric costs but also minimizes wear and tear on equipment, extending the lifespan of both the motors and the systems they power.

Moreover, the implementation of VFMCs contributes to a smoother and more reliable operation of electric motors. They reduce inrush current and mechanical stress during start-up by gradually ramping up motor speed. This controlled start-up process lessens the likelihood of damage and maintenance issues, further enhancing operational efficiency. Additionally, VFMCs often include built-in diagnostics, allowing for proactive maintenance and reducing downtime. Overall, the integration of Variable Frequency Motor Controllers in industrial settings represents a significant advancement towards more sustainable and energy-efficient practices.

Reduction of Energy Consumption Through Variable Speed Control

The advancement of Variable Frequency Motor Controllers (VFMCs), particularly Variable Speed Drives (VSDs), plays a crucial role in energy efficiency and consumption reduction. The global low voltage AC drive market is projected to grow significantly, from $9.38 billion in 2025 to $12.14 billion by 2032, at a CAGR of 3.76%. This growth underscores the industry’s shift towards adopting efficient technologies that leverage speed control for operational excellence. Notably, implementing high-efficiency motors alongside VSDs can cut global energy consumption by as much as 10%, offering a substantial opportunity for industries to minimize their environmental impact.

Moreover, innovations in variable speed technologies have enhanced operational capabilities across multiple sectors. For instance, predictive cruise control in heavy trucks is demonstrated to decrease fuel consumption by nearly 15%. This illustrates the effectiveness of intelligent speed management systems in optimizing energy use. Similarly, as industries continue to embrace variable speed solutions, we can expect further improvements in energy efficiency, leading to reduced carbon emissions and operating costs. Continuous evolution in this field not only contributes to sustainability efforts but also aligns with global energy-saving objectives.

Top Benefits of Variable Frequency Motor Controllers for Efficient Energy Use

This chart illustrates the energy consumption before and after the implementation of Variable Frequency Drive (VFD) systems. As demonstrated, energy consumption significantly decreases from 5000 kWh to 3000 kWh, highlighting the efficiency gained through variable speed control, leading to reduced costs and a smaller carbon footprint.

Impact on Operational Costs: Savings from VFD Implementation

Variable Frequency Drive (VFD) implementation is increasingly recognized as a key strategy for reducing operational costs in various industries. According to the U.S. Department of Energy, VFDs can provide energy savings of 20% to 50% for electric motors, which are responsible for a significant portion of industrial energy consumption, estimated at around 65% of the total electricity used in manufacturing processes. By controlling motor speed and torque according to load requirements, VFDs reduce energy waste, resulting in lower utility bills and enhanced system performance.

In addition to direct energy savings, the adoption of VFDs can lead to reduced wear and tear on mechanical components. A report from the Electric Power Research Institute highlights that VFDs contribute to extending the life of motors and associated equipment by 30% or more, thereby lowering maintenance costs significantly. Over time, these reductions in operational and maintenance expenses can yield a return on investment (ROI) of 200-500%, demonstrating the substantial financial impact of effective energy management through VFD technology.

Top Benefits of Variable Frequency Motor Controllers for Efficient Energy Use - Impact on Operational Costs: Savings from VFD Implementation

| Benefit | Description | Estimated Savings (%) | Payback Period (Years) |

|---|---|---|---|

| Energy Efficiency | VFDs optimize motor speed for varying load conditions, reducing energy consumption. | 20-50% | 1-3 |

| Reduced Wear and Tear | Soft starts reduce mechanical stress on motors and connected equipment, prolonging life. | 15-30% | 2-4 |

| Improved Process Control | Allows for precise control of motor speeds, enhancing production quality. | NA | NA |

| Lower Noise Levels | VFDs reduce speed fluctuations leading to quieter operation. | NA | NA |

| Flexibility in Application | Easily adapt motor operations to dynamic system demands. | NA | NA |

Enhancing Equipment Lifespan and Reliability with VFDs

Variable Frequency Drives (VFDs) play a crucial role in enhancing the lifespan and reliability of industrial equipment. By allowing motors to operate at variable speeds, VFDs optimize energy consumption and reduce wear and tear on components. This increased efficiency not only extends the operational life of machinery but also minimizes maintenance costs. The global variable frequency drive market, valued at approximately $24.68 billion in 2025, is expected to reach $32.00 billion, indicating a growing recognition of the benefits that VFDs provide, particularly in energy-intensive sectors.

In the rapidly evolving plastics production industry, the adoption of VFD technology is becoming increasingly vital for achieving sustainability goals. The demand for efficient energy use is prompting manufacturers to seek advanced solutions that lower operational costs while minimizing environmental impact. As VFDs enable precise control over motor functions, they contribute to the reduction of energy waste and support a more sustainable production model. This shift not only aligns with global sustainability trends but also positions companies to remain competitive in a market that is placing greater emphasis on efficiency and environmental responsibility.

Environmental Benefits: Decreasing Carbon Footprint with Efficient Systems

Variable frequency motor controllers (VFMCs) represent a significant advancement in energy efficiency, offering a pathway to reduce the carbon footprint associated with motor-driven systems. By adjusting the speed and torque of motors to match the operational requirements, these controllers minimize excess energy consumption. This dynamic regulation not only enhances system performance but also contributes to lower greenhouse gas emissions, as motors typically account for a substantial portion of industrial energy use.

Moreover, the integration of VFMCs into manufacturing and utility systems aligns with global sustainability goals. By optimizing energy consumption, organizations can significantly decrease their reliance on fossil fuels, promoting cleaner energy alternatives. This shift not only benefits the environment by reducing air pollution and carbon emissions but also fosters a greener image for businesses. As industries continue to adopt these advanced technologies, the cumulative effect on environmental health could be profound, paving the way for a more sustainable future.

Related Posts

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Understanding Electrical Switches: Key Innovations and Safety Tips for Every Home

-

Top 10 Benefits of Using Manual Motor Starters for Electrical Applications

-

Comprehensive Guide to Optimizing Your Motor and Control Solutions for Enhanced Efficiency