2026 Best Industrial Electric Motors for Optimal Performance?

In the evolving field of manufacturing, choosing the right industrial electric motors is crucial. These motors play a significant role in productivity and efficiency. Different applications require specific types of motors, and knowing which one to select can be challenging.

The 2026 landscape offers a variety of options. Trends suggest a shift toward energy-efficient models, but not all comply with standards. All electric motors are not created equal. Some may underperform in specific settings. These inconsistencies remind us of the importance of thorough research before making a choice.

Investing in high-quality industrial electric motors can make a difference. Performance issues often arise from improper selection. Even top-rated models can struggle if misplaced in applications. Understanding your requirements is essential for achieving optimal results. There is always room for improvement and reflection in this critical decision-making process.

Overview of Industrial Electric Motors: Types and Applications

Industrial electric motors are crucial in various sectors. They drive machinery and equipment, making operations efficient.

These motors come in different types. Common options include AC motors,

DC motors, and stepper motors. Each type has unique applications, suited to specific tasks.

AC motors are prevalent in manufacturing. They are reliable and efficient for continuous operations.

DC motors offer precise speed control, ideal for robotics. Stepper motors are perfect for applications requiring accuracy,

like 3D printers. Choosing the right motor depends on the specific requirements of the task.

Tips: Consider the motor's torque and speed ratings. This information is vital for compatibility.

Inspecting installation requirements can prevent future issues. Always consult technical specifications before making a choice.

These details can save time and resources. Understanding each motor's application enhances performance and efficiency.

Not every motor suits every application, leading to inefficiencies. Reflect on your needs before deciding.

Key Specifications for Selecting High-Performance Electric Motors

When selecting high-performance electric motors, key specifications play a significant role. Efficiency ratings are crucial. A motor with a high efficiency translates to lower energy costs. Look for motors that offer an efficiency above 90%. This can significantly impact long-term operational expenses.

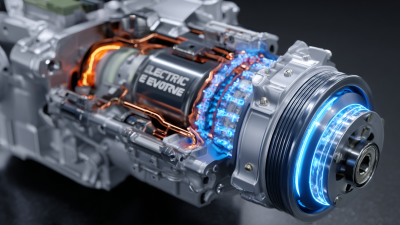

Another important factor is torque ratings. The motor should deliver adequate torque for its intended application. Understand the load requirements before making a choice. A mismatch can lead to underperformance or even failure. Size and weight also matter. A lightweight motor can make installation easier and improve overall system dynamics.

Lastly, consider the thermal performance. Motors often work in extreme heat. Adequate cooling methods, like housing or cooling fins, enhance reliability. Do not overlook noise levels. Sometimes, quieter motors are overlooked, but they significantly improve workplace comfort. Reflect on these aspects to make a better choice. The right specifications ensure optimal performance and longevity.

2026 Best Industrial Electric Motors Performance Analysis

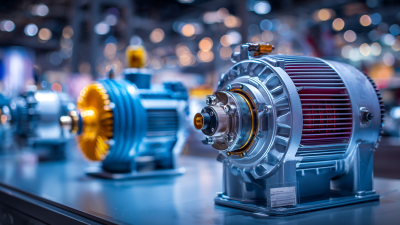

Top Brands and Models of Electric Motors for Industrial Use in 2026

In 2026, the search for high-performance industrial electric motors is more critical than ever. Many industries rely on effective motors to enhance productivity. These motors power various applications, from conveyor systems to pumps. They need to be efficient and durable. Efficiency is key to reducing energy costs. Durable motors minimize downtime in industrial settings.

Several top models stand out in the market. These include variants with advanced cooling systems and improved torque output. Some motors even feature smart technology to monitor performance. However, not all motors meet expectations. Many users report issues with compatibility and installation. It’s essential to evaluate specific needs before making a purchase.

In addition, maintenance remains a challenge. Regular checks are key to ensuring longevity. Some motors require frequent attention, which could lead to increased operational costs. Finding the right balance is crucial. Investing in high-quality motors can yield long-term benefits, but the initial costs can be daunting. Ultimately, companies must weigh the options carefully.

2026 Best Industrial Electric Motors for Optimal Performance

| Model | Power Rating (kW) | Efficiency (%) | Voltage (V) | Speed (RPM) | Weight (kg) | Cooling Method |

|---|---|---|---|---|---|---|

| Model A | 15 | 95 | 400 | 1500 | 120 | Air |

| Model B | 37 | 93 | 460 | 3000 | 200 | Water |

| Model C | 75 | 96 | 600 | 1800 | 250 | Air |

| Model D | 110 | 92 | 690 | 3600 | 300 | Oil |

| Model E | 200 | 94 | 800 | 3600 | 500 | Water |

Energy Efficiency Standards: Impact on Industrial Motor Performance

Energy efficiency standards play a crucial role in industrial motor performance. These standards are designed to reduce energy consumption, which directly affects operational costs. When motors meet efficiency requirements, businesses save money and reduce their carbon footprint. Yet, achieving compliance can be challenging for some manufacturers, leading to increased complexity in motor design.

Many motors now incorporate advanced technologies to enhance efficiency. For instance, improved materials and design elements contribute to better heat dissipation. However, the adoption of these technologies often raises production costs. For smaller companies, these costs can be a significant barrier. The drive for efficiency can sometimes overshadow practical considerations, leading to confusion about which motors truly offer the best value.

Moreover, as standards evolve, businesses must adapt. Not all motors will meet new regulations immediately. This transition period poses challenges, as older systems may not integrate seamlessly with newer, compliant models. Consequently, businesses need to strategize their upgrades and replacements thoughtfully. Balancing performance with compliance requires careful planning and attention to detail.

Future Trends in Electric Motor Technology for Enhanced Productivity

The future of electric motor technology is bright and evolving. New designs are emerging, focusing on efficiency and performance. Manufacturers are harnessing advanced materials to enhance durability. This shift is key for optimal productivity in industrial settings. With innovations in cooling techniques and reduced energy consumption, the potential is vast.

Tips: Consider the lifecycle of your motors. Regular maintenance can prolong their efficiency. Look into predictive maintenance technology to anticipate issues before they arise.

As industries look for sustainable options, electric motors are adapting. The shift toward software integration enables better control and monitoring. However, transitioning can be challenging. Upgrading systems may lead to temporary downtime. Balancing old and new technologies requires careful planning.

Tips: Invest in training for your team. Understanding new systems will help ease transitions. Evaluate your operational needs before making significant changes.

Related Posts

-

Top 10 Types of Industrial Electric Motors You Need to Know about

-

Exploring Electric Motors Innovations at the 2025 China Import and Export Fair

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

-

How to Choose the Right 3 Phase Electric Motor for Your Needs

-

7 Essential Tips for Optimizing Your Electric Motor VFD Efficiency