Why Choose a Motor Contactor for Your Electrical Applications?

In today's fast-paced electrical industry, choosing the right components is crucial. A motor contactor plays a vital role in managing electrical loads efficiently. According to Jane Doe, a seasoned expert in the field, "Selecting the appropriate motor contactor is essential for optimal performance."

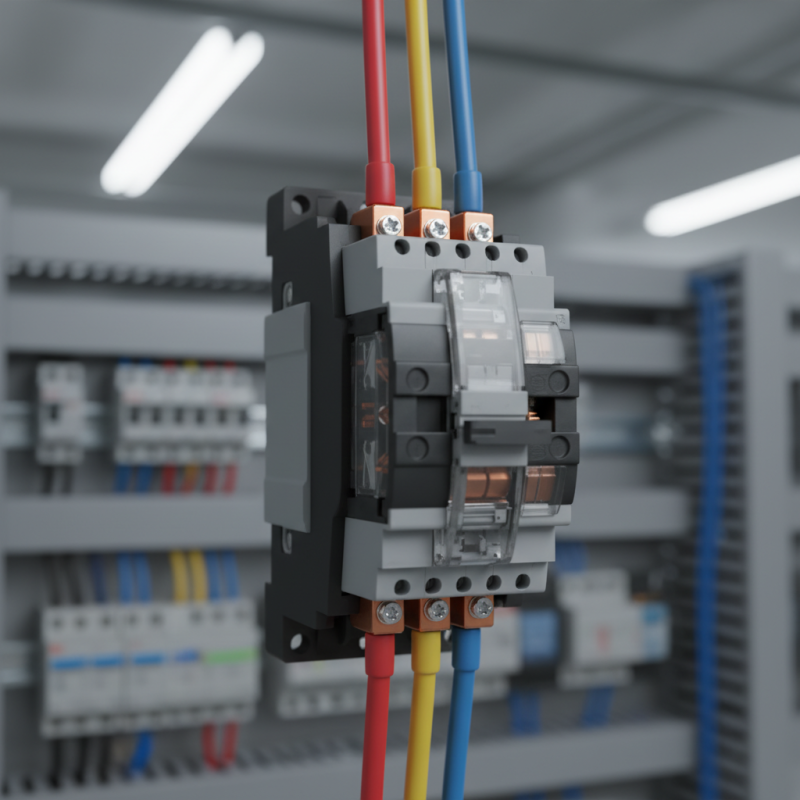

Motor contactors serve as the backbone of various applications, from industrial machinery to HVAC systems. They ensure safe and reliable operation by controlling the power supplied to motors. However, not all motor contactors are created equal. Factors such as load requirements, environmental conditions, and duty cycles need careful consideration.

Many users underestimate the importance of properly sizing motor contactors. This can lead to poor performance or even equipment failure. Awareness of potential mistakes in selection is vital. The right motor contactor can enhance the longevity of electrical systems, but inadequate choices might result in unexpected downtime. Thus, it is crucial to reflect on these decisions to ensure a successful operation.

Why Motor Contactors Are Essential in Electrical Systems

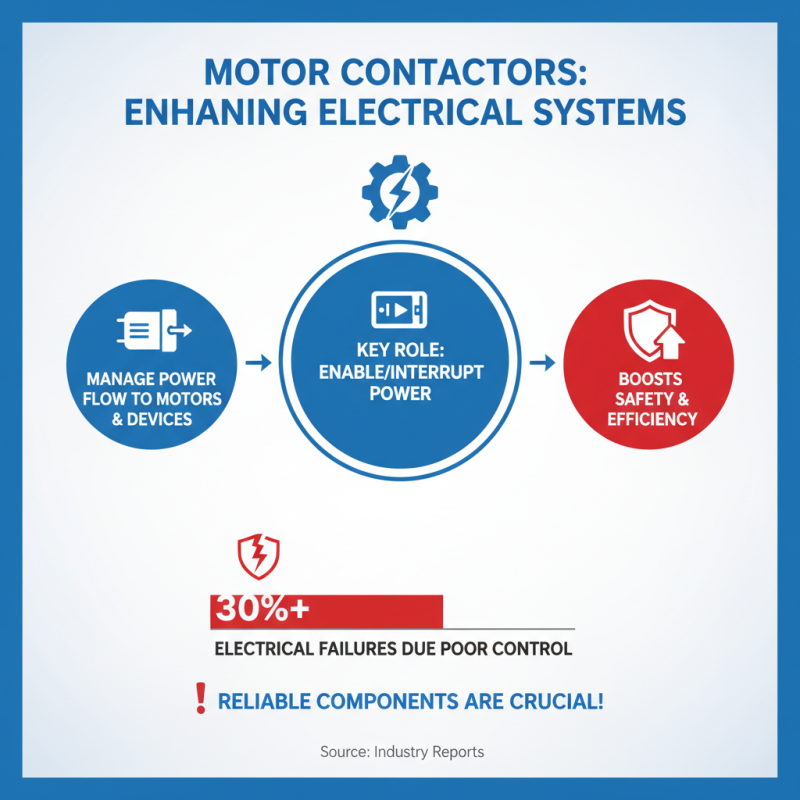

Motor contactors play a crucial role in electrical systems. They regulate the flow of electricity to various components. These devices essentially act as switches that manage heavy electrical loads. This functionality is vital for ensuring safety and efficiency. Faulty or inadequate switching can lead to failures or even hazards. Proper use of motor contactors mitigates such risks.

Additionally, motor contactors are key in automating processes. They allow for remote control of machinery. Operators can start or stop equipment from a safe distance. This convenience enhances operational efficiency and minimizes risks. However, not all systems use contactors effectively. Some may overlook the importance of proper sizing and installation. These oversights can compromise system performance.

Moreover, the longevity of electrical equipment often hinges on the quality of motor contactors. High-quality options can withstand significant wear and tear. However, it’s crucial to regularly inspect these devices. Neglect can lead to unexpected failures and downtime. Awareness of maintenance needs ensures optimal functionality. This ongoing attention to detail can prevent unnecessary breakdowns.

Why Choose a Motor Contactor for Your Electrical Applications?

| Feature | Description | Benefits |

|---|---|---|

| Control Voltage | Standardized control voltages like 24V, 120V, 230V. | Flexibility in system design and compatibility. |

| Current Rating | Available in various ratings typically from 9A to 800A. | Ability to handle diverse electrical loads. |

| Durability | Designed to withstand electrical and mechanical stress. | Long service life and reduced maintenance costs. |

| Safety Features | Inbuilt protection against overload and short circuits. | Enhanced safety for operators and equipment. |

| Control Type | Options for manual, automatic, and remote control. | Versatility in control methods for different applications. |

Understanding the Functionality of Motor Contactors in Circuits

In electrical applications, motor contactors play a crucial role. They help manage the flow of electricity to motors and other devices. By enabling or interrupting power, they enhance safety and efficiency. According to industry reports, over 30% of electrical failures are linked to poor control systems. This emphasizes the need for reliable components like motor contactors.

Tips: Always ensure contactors are rated for the specific application. Overloading them leads to failure. Routine assessments can prevent unexpected breakdowns.

Motor contactors can handle high current loads while remaining compact. This makes them suitable for various circuits, from industrial machinery to HVAC systems. However, improper installation can lead to significant issues. Data indicates that incorrect wiring causes over 20% of system issues. Therefore, understanding the wiring and system requirements is essential.

Tips: Label wires clearly during installation. This helps prevent mistakes and simplifies future maintenance. Consider consulting experts when in doubt.

Key Advantages of Using Motor Contactors Over Other Devices

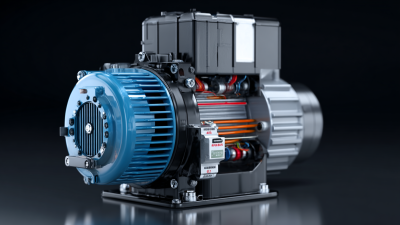

Motor contactors are essential components in many electrical applications. Their ability to handle high current loads makes them a preferred choice for industrial machinery. Unlike relays, which can struggle under heavy loads, motor contactors excel in durability. They provide rapid switching capabilities that can minimize energy waste during on-off cycles. This efficiency can help reduce operational costs over time.

One notable advantage of motor contactors is their robust construction. They typically feature larger contacts and superior insulation compared to other devices. This design choice enhances reliability and reduces the risk of overheating. However, it’s important to choose the right size and rating for specific applications. A miscalculation can lead to inefficient performance.

Another benefit is the safety features inherent in many motor contactors. They often include thermal overload protection. This feature helps prevent damage from overheating. Still, not all models are created equal, and users must regularly check these settings. With regular maintenance, the lifespan of motor contactors can be significantly extended. But neglect can cause unforeseen failures, leading to costly downtimes.

Industry Standards and Ratings for Selecting Motor Contactors

Selecting the right motor contactor for electrical applications involves understanding industry standards and ratings. These standards ensure safety and efficiency. Motor contactors are rated based on their current capacity, voltage, and duty cycle. Knowing these parameters helps prevent equipment failure and enhances performance.

Before purchasing, check for IEC and NEMA ratings. These certifications guarantee that the contactors meet specific safety and operational requirements. Look for thermal and magnetic trip settings. They protect the motor from overloads and short circuits.

Tips: Always match the contactor ratings to your motor specifications. Consider the environment too. Harsh conditions might require specialized contactors.

A common mistake is underestimating how voltage ratings affect performance. Higher voltage ratings can lead to overheating. Regular testing and maintenance are essential. Inspect contactors for wear and tear regularly.

Common Applications and Use Cases for Motor Contactors in Industries

Motor contactors play a critical role in various industrial applications. These devices are designed to control the power supply to motors. According to a recent market report, the global motor contactor market is expected to reach $9 billion by 2026. This growth highlights their importance in sectors such as manufacturing, oil and gas, and HVAC systems.

In manufacturing, motor contactors are often used in conveyor systems. These systems rely heavily on contactors to handle frequent on-off cycling. In HVAC systems, they control compressor operation. Effective contactor operation ensures energy efficiency and maintains equipment longevity. Notably, about 30% of energy costs in manufacturing can be attributed to inefficient motor control.

However, not all applications are straightforward. Choosing the right contactor can be challenging. Incorrect ratings lead to overheating or failure. It's essential to consider factors such as frequency of use, voltage, and environmental conditions. A study found that improper installation led to a 20% increase in equipment downtime. Consulting industry guidelines can mitigate these risks.

Related Posts

-

Understanding Electrical Switches: Choosing the Right Type for Your Home Needs

-

How to Choose the Right 3 Phase Electric Motor for Your Needs

-

How to Choose the Right VFD Motor for Your Industrial Needs in 2025

-

Top 7 Electric Motor Starters for Enhanced Efficiency: Boost Your System’s Performance by 25%!

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions

-

The Future of Electric Motors: Innovations Driving the Next Generation of Sustainable Technology