How to Choose the Right 3 Phase Electric Motor for Your Needs

In today's industrial landscape, selecting the right 3 phase electric motor is crucial for optimizing efficiency and performance in various applications. According to a report by the International Energy Agency (IEA), electric motors account for about 45% of global electricity consumption, underscoring the importance of choosing an appropriate motor for energy savings and operational reliability. With a variety of options available, ranging from NEMA to IEC specifications, understanding the nuances of these motors is essential for engineers and plant managers alike.

Expert insights also emphasize the importance of this decision; Dr. Martin Heller, a leading specialist in electrical engineering, states, "The right choice of a 3 phase electric motor can significantly improve productivity and reduce energy wastage." His research indicates that a well-matched motor can increase efficiency by up to 10%, leading to considerable cost savings over time. This highlights not only the technical aspects but also the economic significance of selecting the correct motor for specific operational requirements. In this guide, we will explore key factors to consider when choosing a 3 phase electric motor that meets your needs efficiently and effectively.

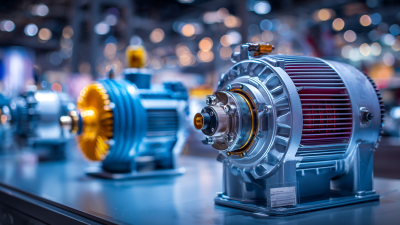

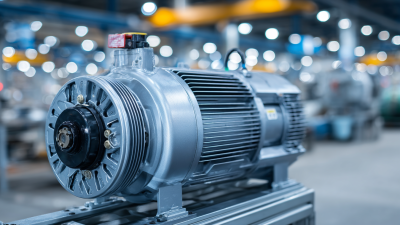

Understanding the Different Types of 3 Phase Electric Motors Available

When choosing a 3 phase electric motor, it is essential to understand the different types available, as each type offers distinct advantages tailored to specific applications. The most common types include squirrel cage motors, wound rotor motors, and synchronous motors. Squirrel cage motors are renowned for their simplicity and durability, making them ideal for general-purpose applications. Wound rotor motors, on the other hand, provide better starting torque and speed control, making them suitable for applications requiring variable loads. Lastly, synchronous motors are used where precise speed control and efficiency are critical, particularly in industrial settings.

**Tips:** When selecting a motor, consider the required torque and speed for your application. Evaluate the operating environment—factors like temperature, humidity, and exposure to dust or chemicals can influence the motor’s performance and lifespan. Additionally, ensure that the motor's power rating aligns with your equipment’s demand to avoid underperformance or overload.

Understanding the purpose of your motor is crucial in making the right choice. For example, if your application involves high starting torque, a wound rotor motor may be more appropriate. Conversely, for continuous duty applications with less fluctuation in load, a squirrel cage motor would likely be the best fit. Always take into account your specific needs and operational constraints to choose the most suitable motor for your project.

How to Choose the Right 3 Phase Electric Motor for Your Needs

| Motor Type | Power Rating (kW) | Voltage (V) | Efficiency (%) | Applications |

|---|---|---|---|---|

| Squirrel Cage Motor | 1.5 | 400 | 90 | Pumps, Fans, Compressors |

| Wound Rotor Motor | 5.5 | 400 | 92 | Crushers, Mixers |

| Permanent Magnet Motor | 3 | 230 | 95 | Electric Vehicles, Robotics |

| Stepper Motor | 0.5 | 220 | 85 | Printers, CNC Machines |

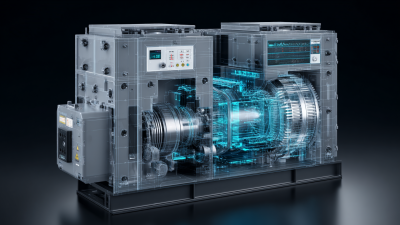

Key Performance Specifications to Consider for Selection

When selecting the appropriate 3 phase electric motor, key performance specifications are critical in ensuring the motor meets operational needs and efficiency goals. One of the primary specifications to consider is the motor's power rating, typically measured in horsepower (HP) or kilowatts (kW). The power rating must align with the requirements of the application while also taking into account any potential overload conditions. According to the Electric Power Research Institute, motors operating close to 75% of their rated capacity tend to perform optimally, prolonging their lifespan and maintaining energy efficiency.

Another essential factor is the motor's efficiency class. The U.S. Department of Energy (DOE) outlines several efficiency standards, with Premium Efficiency motors achieving at least 91% efficiency at full load. Choosing a motor with a higher efficiency rating not only reduces energy consumption but can also lead to significant cost savings over time. Additionally, understanding the startup characteristics, such as inrush current and starting torque, is crucial for applications that require high initial load overcoming, thus ensuring that the system can handle the demands of the service without compromising safety or equipment integrity.

Furthermore, the motor's operating environment, including ambient temperature and potential exposure to dust or moisture, influences the selection process. A study from the International Electrotechnical Commission emphasizes that selecting a motor with an appropriate enclosure rating, such as IP54 for dust and moisture resistance, is vital for maintaining performance and reducing maintenance costs in industrial settings. By carefully assessing these performance specifications, users can ensure they choose the right 3 phase electric motor for their specific applications.

3 Phase Electric Motor Performance Comparison

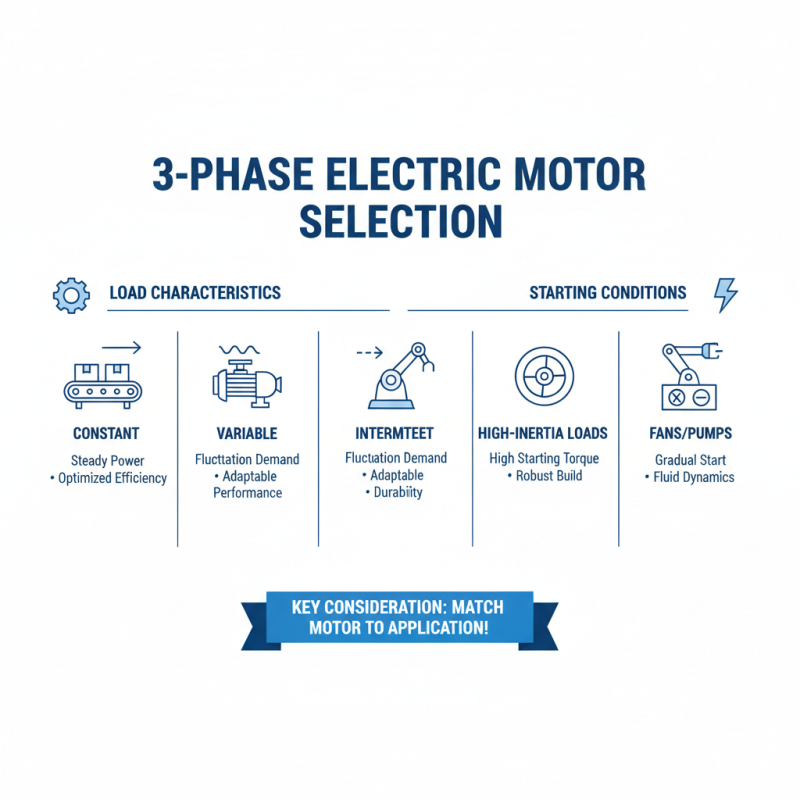

Evaluating Load Characteristics and Application Requirements

When selecting the right 3-phase electric motor, it is crucial to evaluate the load characteristics of the application. This includes understanding the type of load—whether it’s constant, variable, or has intermittent demand. A constant load might require a motor that operates efficiently within a specific power range, while variable loads may necessitate a motor capable of handling fluctuations in demand without compromising performance. Additionally, it's important to consider the starting conditions; for instance, motors dealing with high-inertia loads will have different requirements compared to those driving fans or pumps.

Application requirements also play a vital role in motor selection. Factors such as the desired speed range, efficiency ratings, and environmental conditions—like temperature and humidity—should all be considered. A motor designed for outdoor use must have adequate protection against the elements, while motors used in precision applications need to maintain strict speed and torque controls. Furthermore, the compatibility with existing electrical systems and the need for dynamic braking or variable frequency drives can influence the choice. By thoroughly evaluating these characteristics, users can ensure they select a motor that not only meets their current needs but also offers flexibility for future applications.

Energy Efficiency Ratings: Importance and Comparison of Motors

When selecting a three-phase electric motor, energy efficiency ratings play a crucial role in ensuring that the motor meets both operational requirements and sustainability goals. These ratings indicate how effectively the motor converts electrical energy into mechanical energy, typically expressed as a percentage. Higher efficiency ratings often correlate with lower operational costs over the motor's lifetime, making them an essential factor in both commercial and industrial applications.

In addition to direct operational costs, energy-efficient motors also contribute to reducing the overall environmental footprint of an operation. Compared to less efficient models, these motors consume less electricity, which not only lowers energy expenses but also minimizes greenhouse gas emissions associated with electricity production. When comparing motors, it is essential to look for compliance with established efficiency standards, such as those set by international organizations.

This comparison allows users to make informed decisions, balancing upfront costs with long-term savings and ecological considerations. Ultimately, selecting a motor with a higher energy efficiency rating can lead to significant operational benefits and strides toward sustainability.

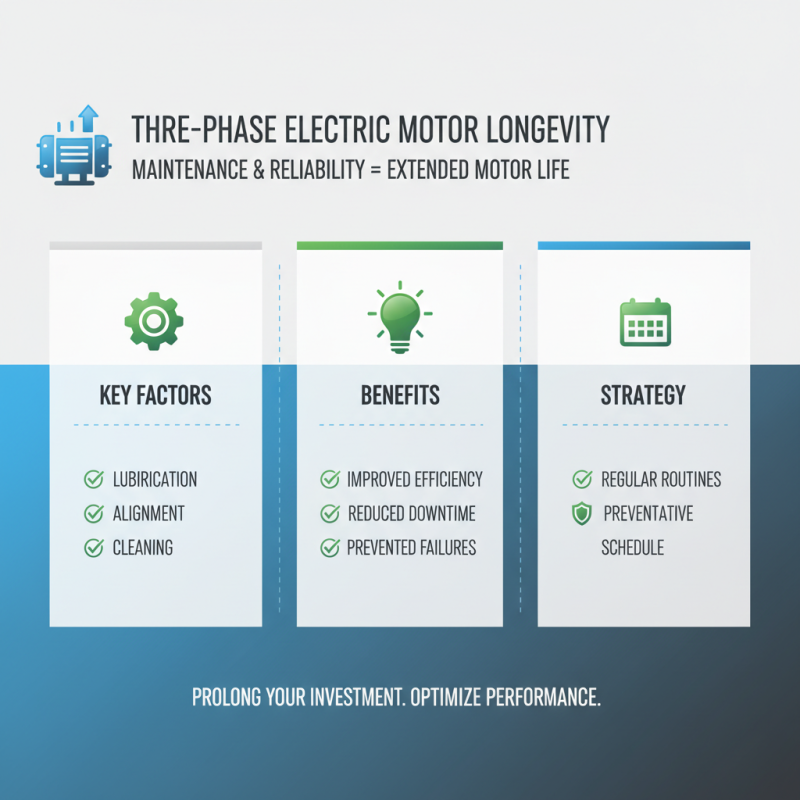

Maintenance and Reliability Factors Affecting Motor Longevity

When selecting a three-phase electric motor, understanding the maintenance and reliability factors that affect motor longevity is crucial. A well-maintained motor can vastly outperform one that is neglected, leading to improved efficiency and reduced downtime. Regular maintenance routines, including lubrication, alignment checks, and cleaning, help prevent common issues such as overheating or mechanical failure. Implementing a preventive maintenance schedule ensures that potential problems are identified and addressed before they escalate.

Moreover, the reliability of a motor is influenced by its installation and operating conditions. Factors such as ambient temperature, humidity, and exposure to contaminants can significantly impact a motor's lifespan. Proper installation techniques, such as ensuring adequate ventilation and using suitable protective enclosures, can enhance reliability. Additionally, operating the motor within its specified limits prevents undue stress that could lead to premature wear. By focusing on these maintenance and reliability factors, users can maximize the operational life of their three-phase electric motors, ultimately ensuring efficient and uninterrupted performance in their applications.

Related Posts

-

Exploring Electric Motors Innovations at the 2025 China Import and Export Fair

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

7 Essential Tips for Optimizing Your Electric Motor VFD Efficiency

-

Understanding the Role of 3 Phase Electric Motors in Modern Industrial Applications

-

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions