How to Choose the Right 3 Phase Motor Starter for Optimal Performance and Efficiency

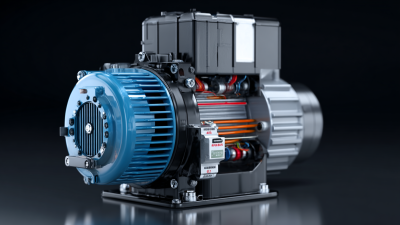

In the industrial landscape, the selection of motor starters is critical for the performance and efficiency of electric motors, particularly for 3 phase motors, which account for approximately 90% of the total motor use in manufacturing applications according to the U.S. Department of Energy. A 3 phase motor starter not only protects the motor from damage due to overloads and phase failures but also enhances the energy efficiency of electrical systems. With the growing emphasis on optimizing operational costs, businesses are increasingly relying on advanced motor starters to ensure reliable performance and extended motor life.

Selecting the right 3 phase motor starter is essential for achieving optimal performance, as it directly affects power consumption, operational costs, and adherence to international efficiency standards. Recent studies show that utilizing modern motor starter technologies can improve energy savings by up to 30%, significantly impacting the bottom line. Thus, understanding the features, benefits, and application contexts of various 3 phase motor starters can empower engineers and decision-makers to make informed choices that align with their operational goals, ensuring both sustainability and profitability in their electrical systems.

Understanding the Different Types of 3 Phase Motor Starters Available in the Market

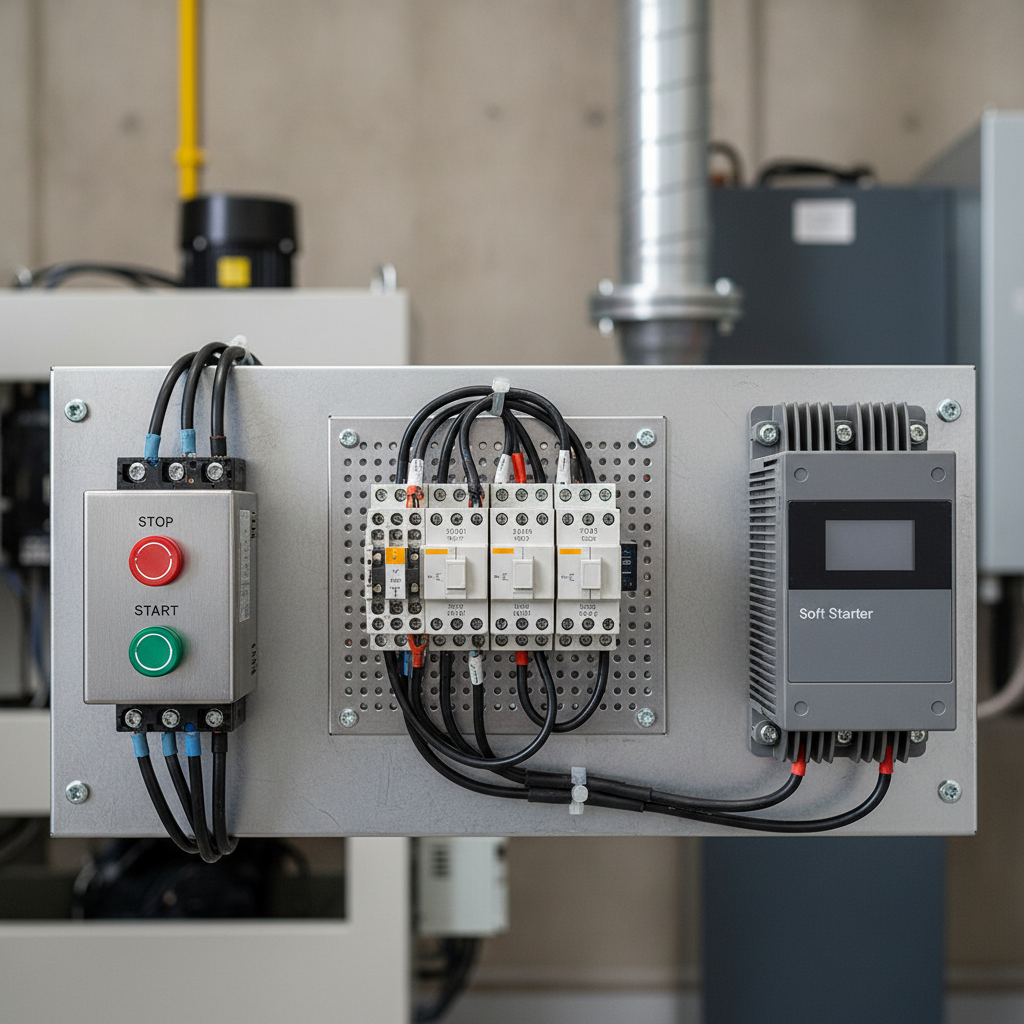

When selecting a three-phase motor starter, it is essential to understand the various types available in the market, as each type serves a different purpose and offers distinct advantages. The most common types include direct-on-line (DOL) starters, star-delta starters, and soft starters.

DOL starters are straightforward and ideal for smaller motors where high starting torque is not an issue. They allow for immediate power supply to the motor, enabling a quick start but can lead to high inrush currents.

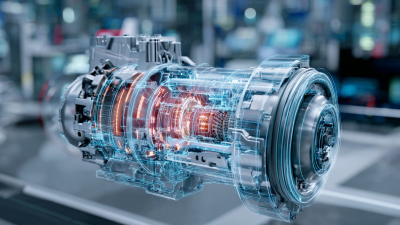

Star-delta starters are advantageous for larger motors, as they reduce the starting current and torque by initially connecting the motor in a star configuration before switching to the delta configuration once the motor reaches a certain speed. This method helps to minimize electrical stress and prolongs the lifespan of the motor. Additionally, soft starters offer smooth acceleration by gradually increasing the voltage supplied to the motor, which reduces mechanical stress and energy consumption during startup. Each of these starter types has its unique functionalities, making it crucial for users to assess their motor specifications and application requirements to select the appropriate starter for optimal performance and efficiency.

Key Performance Metrics for Selecting the Right 3 Phase Motor Starter

When selecting a three-phase motor starter, understanding key performance metrics is crucial for ensuring optimal operation. One of the primary metrics to consider is the motor's starting current, which typically peaks during startup. A motor starter should be capable of handling this initial surge without compromising the system's integrity. Additionally, the starter must provide appropriate overload protection to prevent damage due to prolonged excessive current. This entails verifying that the starter's settings align with the motor's specifications and operational demands.

Another important metric is the motor's starting method, which can significantly affect performance and efficiency. Different starters—such as direct-on-line, star-delta, or autotransformer starters—offer distinct advantages depending on the specific application and required starting torque. The suitability of these methods should be assessed based on the motor's load characteristics, duty cycle, and the operational environment. Lastly, robust control features, such as soft-start capabilities, contribute to reduced mechanical stress and improve energy efficiency during the startup phase, making them a vital part of the selection process.

Evaluating Efficiency Ratings: How to Assess Motor Starter Energy Consumption

When selecting a three-phase motor starter, evaluating its energy consumption is crucial for ensuring optimal performance and efficiency. According to the U.S. Department of Energy, motors account for nearly 70% of industrial electricity consumption, and efficient motor starters can significantly reduce energy waste. An efficient motor starter not only enhances performance but also extends the lifespan of the motor, reducing the need for replacements and maintenance costs.

One effective way to assess energy consumption is by examining the starter's efficiency rating. The National Electrical Manufacturers Association (NEMA) recommends looking for starters with high efficiency ratings, such as those compliant with the latest efficiency standards set forth by the International Electrotechnical Commission (IEC). Studies show that motor starters with a high efficiency rating can yield energy savings of up to 30%, making a considerable impact on operational costs. Furthermore, incorporating variable frequency drives (VFDs) can optimize motor performance by adjusting speed and torque, which ensures that energy is used only as needed during operation.

Energy Efficiency of Different 3 Phase Motor Starters

Critical Features to Look for in a High-Quality 3 Phase Motor Starter

When selecting a three-phase motor starter, certain critical features can significantly impact the performance and efficiency of your motor systems. Firstly, the starter should incorporate overload protection, which prevents the motor from drawing excessive current that can lead to overheating and eventual failure. According to the National Electrical Manufacturers Association (NEMA), proper overload protection can enhance motor lifespan by as much as 25%, thereby reducing maintenance costs and downtime.

Another essential feature is the control circuit's ability to provide effective short-circuit protection. A study by the Electrical Safety Foundation International (ESFI) indicates that nearly 30% of electrical failures in industrial settings are linked to inadequate short-circuit protection. Thus, choosing a starter with robust circuit-breaking capabilities is not only critical for safety but also for maintaining operational efficiency. Additionally, consider starters with adjustable settings, as they allow fine-tuning of the motor's performance characteristics, leading to optimal energy consumption—potentially reducing operational costs by 10-20%.

Incorporating these features into your selection criteria ensures that you are not only safeguarding your equipment but also enhancing the overall efficiency of your operations.

How to Choose the Right 3 Phase Motor Starter for Optimal Performance and Efficiency - Critical Features to Look for in a High-Quality 3 Phase Motor Starter

| Feature | Importance | Ideal Rating | Common Specifications |

|---|---|---|---|

| Overload Protection | Prevents motor damage from overloads | Adjustable setting based on motor specs | Typically 1.1 to 1.6 times Full Load Current |

| Starting Method | Minimizes inrush current during startup | Soft start or Star Delta | Adjustable ramp time up to 10 seconds |

| Control Voltage | Ensures safe operation and compatibility | 24V AC/DC or 110V AC | Commonly 24V for safety and efficiency |

| Fuse/Breaker Size | Protects circuits from overload and short circuits | Equal to or slightly greater than motor FLC | Typically 125%-150% of Full Load Current |

| Temperature Ratings | Ensures reliable operation in various environments | -20°C to 50°C or higher | Choose based on installation location |

Industry Standards and Compliance: Ensuring Optimal Performance in Motor Starters

When selecting a 3-phase motor starter, adherence to industry standards and compliance is crucial for ensuring optimal performance and efficiency.

According to the National Electrical Manufacturers Association (NEMA), motors account for approximately 70% of industrial electricity consumption, making the choice of the right motor starter pivotal. Utilizing starters that meet NEMA standards can prevent overheating and prolong the lifespan of both the motor and the starter, thereby enhancing energy efficiency and reducing maintenance costs.

Compliance with the International Electrotechnical Commission (IEC) standards also plays a vital role in motor starter selection. IEC standards focus on various safety and performance criteria, ensuring that the motor starters can handle overloads, short circuits, and other electrical faults.

A report from the Department of Energy (DOE) highlights that properly designed motor starters can improve overall system efficiency by more than 15%, showcasing the potential energy savings and reduced operational costs. Thus, manufacturers and facility managers must prioritize compliance with these standards to achieve reliable and efficient motor starter performance.

Related Posts

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

Exploring Manual Motor Starter Innovations at the 138th China Import and Export Fair in 2025

-

Maximizing Efficiency: How Advanced Motor Starters Improve Energy Consumption in Industrial Applications

-

Top 7 Electric Motor Starters for Enhanced Efficiency: Boost Your System’s Performance by 25%!

-

Understanding the Future of Motors and Controls in Sustainable Technology