How to Choose the Right Electric Motor Controller for Your Project?

Choosing the right electric motor controller for your project can feel overwhelming. There are so many options available. Each controller offers different features. You must consider your specific needs before making a decision.

Key factors to evaluate include voltage, current ratings, and control methods. Think about the environment where the motor will operate. Will it face extreme temperatures? This can impact controller performance.

Sometimes people overlook important specifications. They focus only on price or brand. However, this can lead to complications later. Assessing all aspects helps avoid future issues. A smart choice today can enhance efficiency and reliability in your project.

Understanding the Types of Electric Motor Controllers Available in the Market

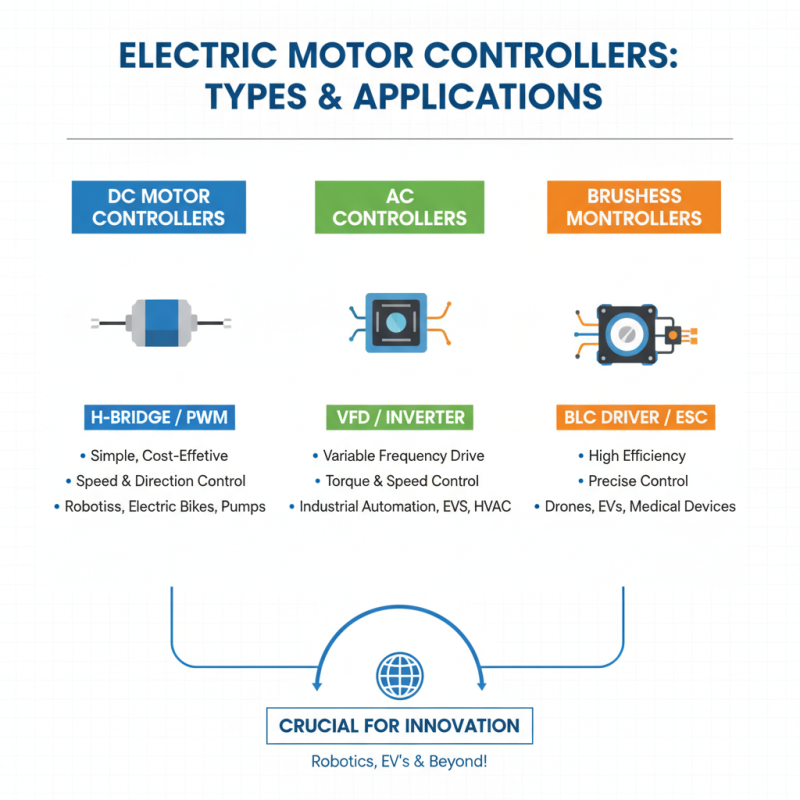

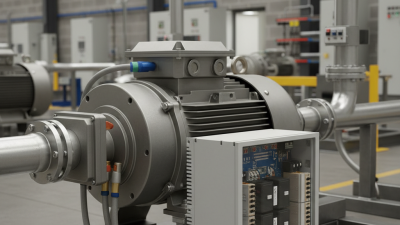

Electric motor controllers are vital for various applications, including robotics and electric vehicles. Understanding the types available is crucial for project success. Controllers generally fall into three categories: DC Motor Controllers, AC Motor Controllers, and Brushless Motor Controllers. Each has its unique features and advantages.

DC Motor Controllers offer simple control for low-power applications. They can manage speed and direction effectively. According to a recent market analysis, the demand for DC controllers is steadily rising. AC Motor Controllers are more complex but suitable for high-power needs. They provide better efficiency and performance. However, they require more knowledge to implement correctly. Brushless Motor Controllers are optimal for applications needing high precision, but they come with a steep learning curve.

Choosing the right controller can be daunting. Compatibility with your motor is essential. Many users report compatibility issues that stem from misunderstanding essential specifications. Ignoring this can lead to inefficient performance. Research shows that 37% of DIY projects fail due to improper controller selection. It's vital to analyze your project requirements thoroughly before making a choice. Each project can benefit from different controller types, but the wrong decision could be costly.

Key Specifications to Consider When Selecting an Electric Motor Controller

Selecting the right electric motor controller is crucial for your project's success. Key specifications play a vital role in this choice. Begin with voltage and current ratings. Ensure the controller can handle your motor's specifications without overheating. A mismatch here can lead to failure. Pay attention to the power output too. It should match your motor's requirements.

Another important aspect is the control method. Different projects may need different control modes. Choose between PWM, analog, or digital control based on your application. Additionally, consider size and weight. A bulky controller may not fit in compact setups. Compatibility with other components is also essential.

Finally, think about the efficiency of the controller. Higher efficiency means less wasted energy. It can lead to better performance and longer battery life. Don't forget to check for features like thermal protection and feedback loops. These can help improve reliability. Balancing these specifications requires careful thought. Mistakes can lead to project delays or additional costs.

Analyzing Application Requirements for Optimal Motor Controller Performance

Choosing the right electric motor controller is crucial. Analyzing application requirements helps in achieving optimal performance. Different projects demand different specifications. For example, a report from Allied Market Research indicates that the global market for motor controllers is projected to reach $18.12 billion by 2027, reflecting a growing demand.

Power and efficiency are key factors. Understanding voltage and current ratings can prevent issues. A controller with a certain power rating might not perform well in high-load situations. This mismatch can lead to overheating or system failure. An analysis by ResearchAndMarkets showed that the efficiency rate of motor controllers can vary widely. Some achieve over 95%, while others fall significantly short.

Additionally, consider control methods. Open-loop and closed-loop systems each have their pros and cons. Open-loop systems are simpler but may lack precision. Closed-loop systems can improve performance but add complexity. Reflecting on these factors helps in making informed choices. Avoid overlooking nuances in application requirements. They often dictate the success of your project.

How to Choose the Right Electric Motor Controller for Your Project? - Analyzing Application Requirements for Optimal Motor Controller Performance

| Parameter | Description | Value/Specifications |

|---|---|---|

| Voltage Rating | Operating voltage of the motor controller | 12V, 24V, 48V, 72V |

| Current Rating | Maximum continuous current that can be handled | 10A, 20A, 40A, 100A |

| Control Type | Type of control used by the motor controller | PWM, SPWM, FOC |

| Feedback System | System used for feedback regarding motor position and speed | Hall effect sensors, encoder, open-loop |

| Protection Features | Built-in safety features to protect against faults | Over-voltage, under-voltage, over-temperature, short-circuit |

| Size/Weight | Physical dimensions and weight of the controller | 150mm x 100mm x 50mm, 1.5kg |

| Temperature Range | Operating temperature range | -20°C to +60°C |

| Communication Protocol | Supported communication interfaces for integration | CAN, RS-485, UART |

Evaluating the Cost-Benefit Ratio of Different Electric Motor Controllers

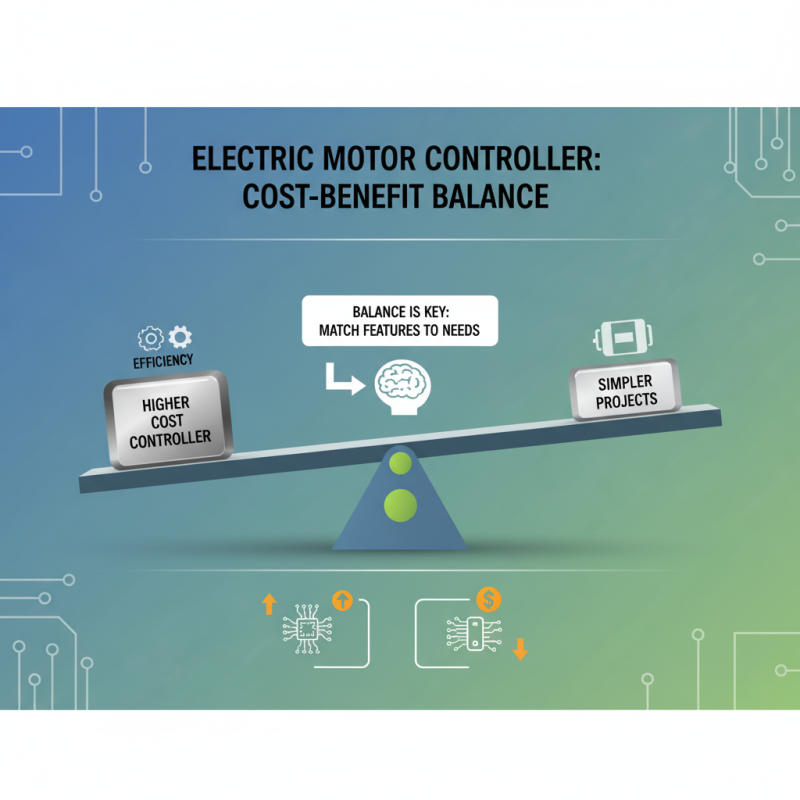

When choosing the right electric motor controller, it's essential to evaluate the cost-benefit ratio. Many options are available, each with its unique advantages and disadvantages. A more expensive controller might offer better efficiency, but it could be unnecessary for simpler projects. Balance is key.

Consider the lifetime costs. An inexpensive controller may save you money upfront. However, higher maintenance costs can negate those savings. Look at the long-term usage and reliability. Sometimes spending a bit more can lead to fewer problems down the road.

Tips: Always calculate power requirements first. Match the controller’s specifications with your motor's needs. Also, assess your project's goals. A high-performance controller may be overkill for light tasks. Finally, research reviews to gauge real user experiences. This can provide insights that data sheets often omit.

Future Trends in Electric Motor Controllers: Technology and Efficiency Advances

The evolution of electric motor controllers is remarkable. Recent data indicates that the global electric motor controller market is projected to reach approximately $30 billion by 2027. This growth correlates with advancements in technology and efficiency. More manufacturers are focusing on smart controllers that enhance functionality and reduce energy consumption. These innovations allow for better integration with renewable energy sources.

One notable trend is the rise of digital controllers. Unlike their analog predecessors, digital versions offer precise control and improved diagnostics. According to a report by industry analysts, the efficiency of electric motor controllers has increased by 20% over the past five years. However, challenges exist. Many projects still struggle with compatibility between older motors and advanced controllers. This disconnect can lead to increased costs and inefficiency.

Battery-powered systems are becoming more prevalent. It's critical for designers to choose controllers that optimize battery use. Some experts suggest that optimizing efficiency can enhance battery lifespan by up to 30%. Nonetheless, misconceptions about controller capabilities continue to undermine project effectiveness. Designers must remain proactive in understanding technology’s impact on performance and sustainability.

Related Posts

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

Exploring Electric Motor Controller Innovations at the 2025 China 138th Canton Fair

-

Understanding Electrical Switches: Key Innovations and Safety Tips for Every Home

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications

-

How to Choose the Right Circuit Breaker for Your Home Electrical System

-

Why Do You Need a Soft Starter for Your Electrical Motor System?