How to Choose the Right Electrical Switchgear for Your Needs

Choosing the right electrical switchgear is critical for efficient power management. In 2022, the global switchgear market was valued at $100 billion and is projected to grow significantly. Such growth highlights the importance of selecting high-quality equipment. Industry expert Dr. Jane Thompson emphasizes, “The right electrical switchgear can dramatically impact system reliability and safety.”

When considering electrical switchgear, it is essential to evaluate various factors. These include voltage ratings, control features, and environment suitability. For instance, indoor switchgear offers distinct advantages in urban areas, but outdoor options might be necessary for harsher climates. Not all equipment performs equally under different conditions. Thus, understanding specific requirements is vital.

In practice, many businesses overlook the long-term implications of their choices. This oversight can lead to costly upgrades or safety hazards. Investing time in research can save resources down the line. Choosing the right electrical switchgear not only enhances efficiency but also ensures safety and compliance.

Understanding Electrical Switchgear and Its Functions

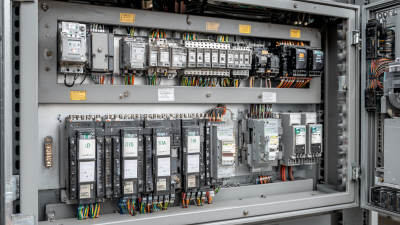

Electrical switchgear plays a crucial role in power distribution systems.

It provides protection, control, and isolation for electrical circuits.

Understanding how switchgear works is essential for making informed decisions about your electrical needs.

Each component, such as breakers and fuses, serves a specific purpose. Knowing these functions helps in selecting the most suitable switchgear.

In a typical setup, switchgear ensures safety during maintenance. It prevents accidental energization of circuits.

However, choosing the right type can be challenging. Some may overlook the voltage ratings or fail to account for load requirements.

This oversight could lead to system failures or even hazards. Evaluating these factors is critical for effective performance and safety.

Another point to consider is the environment.

Indoor switchgear differs significantly from outdoor ones. Outdoor units often include additional weatherproofing features.

Neglecting this can lead to premature failure. It's important to reflect on site conditions and future expansions when selecting switchgear.

Balancing performance, safety, and space needs is a complex task.

Identifying Different Types of Electrical Switchgear Options

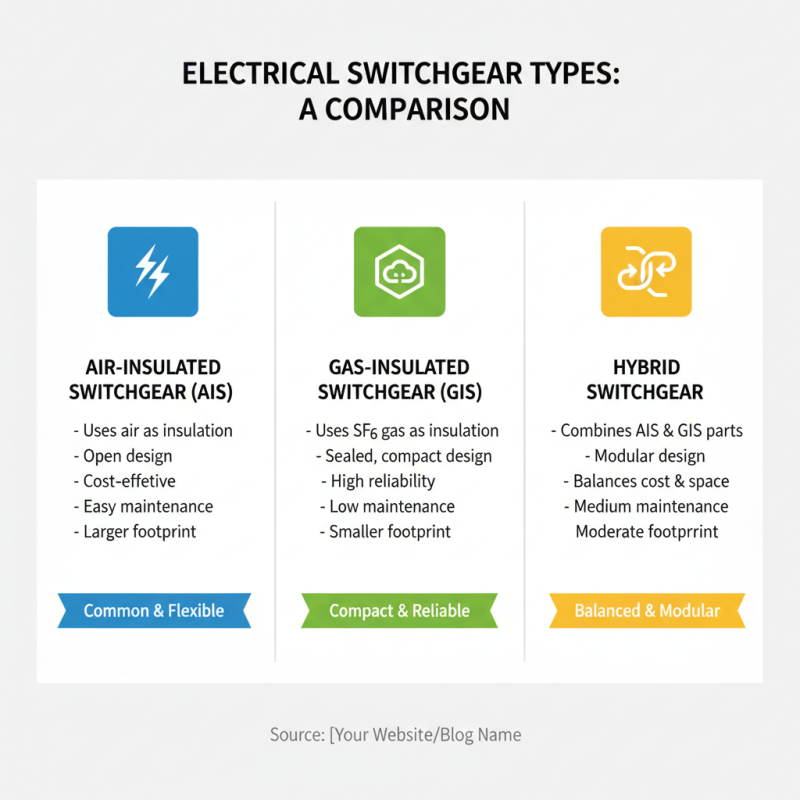

When selecting electrical switchgear, it’s crucial to understand the different options available. Switchgear types can vary significantly. Common categories include air-insulated switchgear (AIS), gas-insulated switchgear (GIS), and hybrid switchgear. Each has unique benefits and limitations.

Air-insulated switchgear is widely used for its cost-effectiveness. However, it requires more space and is less suitable for urban areas. In contrast, gas-insulated switchgear occupies a smaller footprint. It’s ideal for locations with limited space but tends to be pricier. A report by the International Energy Agency highlights that GIS usage is increasing, projected to grow by 15% by 2025 in urban installations.

Hybrid switchgear combines both technologies. It offers flexibility but can be complex and requires skilled personnel for maintenance. An analysis from the Electrical Power Research Institute suggests that hybrid solutions often face challenges in integration. Companies must weigh these pros and cons. Understanding your specific needs, such as space, budget, and technical expertise, will guide you in making an informed choice.

Determining Your Power Requirements for Switchgear Selection

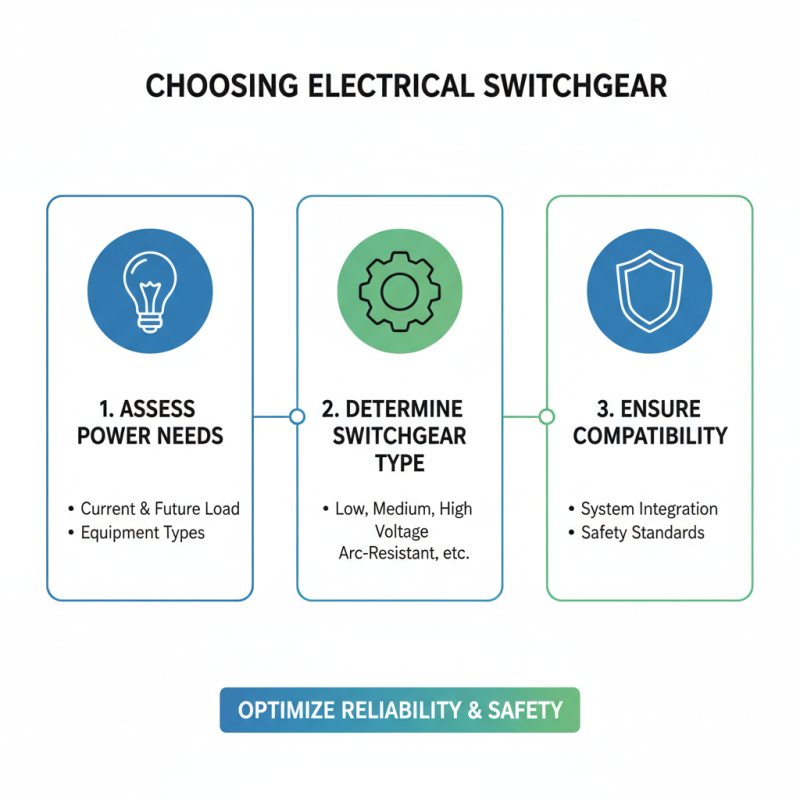

Choosing the right electrical switchgear requires a clear understanding of your power needs. Begin by assessing your current and future electrical load. Consider the types of equipment and machinery you will be using. This helps ensure that the switchgear can handle the necessary power demands without overloading.

**Tip:** Calculate your maximum power requirements by adding up the wattage of all devices. Always account for peak loads. This gives you a more accurate picture of what you need.

Also, think about safety and space. Is there sufficient room for installation? Are you complying with local regulations? It’s essential to evaluate the physical constraints. Some projects may require customized solutions, which involves more planning and expense.

**Tip:** Engage with an electrical engineer. Their expertise can provide insights that may not be immediately evident. Leverage their knowledge to avoid costly mistakes down the road.

Remember, clarity in your requirements will lead to better decisions. Power demands and installation challenges are intertwined. Make adjustments as necessary, and stay flexible in your planning process.

Key Factors to Consider When Choosing Switchgear

Choosing the right electrical switchgear is crucial for your project. Understanding the key factors helps in making an informed decision. One important aspect is the application of the switchgear. Different settings have varying demands. For instance, residential needs differ from industrial requirements.

Another factor is the voltage rating. Ensure the switchgear can handle your specific voltage levels. Underestimating this can lead to failures. The environment where the switchgear will be installed is essential too. Will it be in a dusty, humid, or cold place? This can affect its performance and lifespan.

Tips: Always consider the safety features. Circuit protection must be adequate to prevent electrical hazards. Also, think about future needs. Will you need more capacity later? Planning can save costs down the line.

It’s not always easy to find the perfect fit. Sometimes, compromises are necessary. Reflect on your choices and adapt as needed.

Maintenance and Safety Considerations for Electrical Switchgear

When it comes to electrical switchgear, maintenance and safety are paramount. Regular inspections can prevent unexpected failures. Check for signs of wear, loose connections, and burnt components. These minor issues can escalate quickly. Set up a periodic maintenance schedule. This helps catch problems early.

Safety measures are crucial. Always de-energize switchgear before working on it. Use proper personal protective equipment. This includes insulated gloves and face shields. Accidents can happen, even in seemingly safe environments. Training personnel on safety protocols is essential. Everyone should understand the risks involved.

Equipment should be properly labeled. This ensures that workers know what they’re dealing with. Clear signage can prevent mishaps. However, labeling alone isn't enough. Reflect on whether the current system meets your needs. Are there gaps? Regularly update safety protocols in line with new findings. Staying proactive is necessary for maintaining a safe working environment.

Related Posts

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs

-

2025 How to Choose the Right Electrical Switchgear for Your Needs

-

What is Electrical Switchgear and How Does it Work?

-

How to Choose the Right VFD Drive for Your Industrial Applications?

-

Top 5 Benefits of Using a 3 Phase Motor Starter for Efficient Performance