How to Choose the Right VFD Motor for Your Industrial Needs in 2025

In the rapidly evolving industrial landscape of 2025, the selection of a Variable Frequency Drive (VFD) motor is critical to optimizing operational efficiency and energy consumption. Recent reports indicate that the global VFD market is projected to reach approximately USD 20 billion by 2025, reflecting a significant increase in the adoption of these motors across various sectors, including manufacturing, HVAC, and renewable energy. This trend underscores the growing recognition of VFD motors as essential components in enhancing energy efficiency, reducing operational costs, and improving process control.

As industries increasingly prioritize sustainability and cost-effectiveness, understanding the intricacies of VFD motors becomes paramount. Data shows that VFD motors can reduce energy consumption by as much as 30-50%, particularly in applications involving variable loads. Furthermore, with advancements in technology, new features such as integrated software for real-time monitoring and control are becoming common, offering manufacturers improved insights into performance metrics. With such compelling drivers, choosing the right VFD motor involves a comprehensive assessment of operational needs, application types, and energy-saving goals. Therefore, informed decision-making is crucial for maximizing the benefits associated with VFD motor implementation in industrial applications.

Understanding VFD Motors: What They Are and How They Work

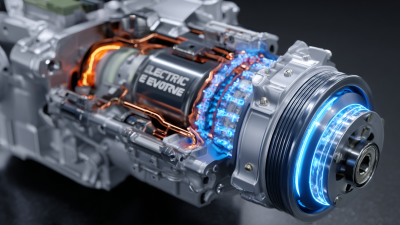

Variable Frequency Drive (VFD) motors are essential components in modern industrial applications, allowing for precise control of motor speed and torque. A VFD operates by converting the fixed frequency AC voltage from the power supply into a variable frequency output voltage. This capability not only enables energy savings by matching the motor speed to the load requirements but also helps to extend the lifespan of the motor due to reduced mechanical stress during startup and operation.

Understanding how VFD motors function requires a grasp of key components such as the rectifier, DC bus, and inverter. The rectifier first converts the incoming AC supply into DC, which is then smoothed out in the DC bus. Finally, the inverter converts this DC back into AC at the desired frequency and voltage, allowing for the control of motor speed. This flexibility makes VFD motors particularly valuable in applications ranging from pumps and fans to conveyors and compressors, where varying operational demands are common. The ability to fine-tune motor performance directly correlates with improved efficiency and reduced operational costs for industrial facilities.

VFD Motor Efficiency Ratings in 2025

Key Factors to Consider When Choosing a VFD Motor for Industries

When selecting a Variable Frequency Drive (VFD) motor for industrial applications in 2025, several key factors must be taken into account to ensure operational efficiency and compatibility with specific processes. First and foremost, understanding the load requirements is crucial. Depending on whether the motor will be driving pumps, fans, or conveyors, the torque and speed characteristics must align with the operational demands. Assessing whether the application requires constant torque or variable torque capabilities will significantly influence the choice of the motor.

Another critical consideration is the motor's efficiency ratings. In an era where energy savings and sustainability are paramount, selecting a VFD motor that meets or exceeds current efficiency standards will help reduce operating costs and minimize environmental impact. Additionally, the compatibility of the VFD motor with existing automation systems and control technologies should be evaluated, ensuring seamless integration for optimal performance. Factors such as the operating environment, including temperature, humidity, and exposure to contaminants, also play a vital role in determining the right motor specifications, as they can greatly affect reliability and lifespan.

How to Choose the Right VFD Motor for Your Industrial Needs in 2025

| Factor | Description | Considerations |

|---|---|---|

| Power Rating | The required horsepower or kilowatt rating necessary for your application. | Choose a motor that provides 10% extra capacity to account for overloads. |

| Application Type | The specific tasks the motor will perform, such as pumps, fans, or conveyors. | Consider the torque requirements and the duty cycle of the application. |

| Operating Environment | Location conditions such as temperature, humidity, and exposure to dust or chemicals. | Select a motor with appropriate enclosures and protection ratings (like IP ratings). |

| Control Features | The advanced features available for controlling motor speed and torque. | Look for motors with built-in sensors and communication protocols for automation. |

| Efficiency Ratings | Energy efficiency levels, often rated by NEMA or IE standards. | Higher efficiency motors can reduce operational costs significantly. |

| Size and Mounting | Physical dimensions and mounting options based on your installation space. | Ensure the motor fits within your equipment's footprint and consider vibration impacts. |

Evaluating Motor Specifications: Power, Speed, and Efficiency Requirements

When selecting a Variable Frequency Drive (VFD) motor for industrial applications in 2025, understanding motor specifications is crucial. Power rating is one of the primary factors to evaluate, as it dictates the motor's capability to perform tasks efficiently and effectively. The power requirement of your application will impact the size and performance of the motor. Ensure that the motor's power rating aligns with the load it will carry to avoid underperformance or overloading, which could lead to premature failure.

Speed specifications are also vital as they determine how quickly the motor can operate. Depending on the nature of your application, different operations might require varying speeds. For instance, processes that involve conveyor systems may necessitate adjustable speed settings to optimize throughput. Consider selecting a VFD motor that provides flexible speed control, allowing you to tailor the operation based on your production needs.

Tip: Always consult your operation's specific demands before finalizing your selection, as this will ensure you choose a VFD motor that enhances productivity and maintains energy efficiency. Additionally, efficiency ratings are crucial as they directly correlate to energy costs and environmental impact. Opt for motors with higher efficiency to reduce operational expenses in the long run. This balance of power, speed, and efficiency will lead to the most suitable VFD motor for your industrial requirements.

Integration Considerations: Compatibility with Existing Systems and Controls

When selecting a Variable Frequency Drive (VFD) motor for industrial applications, compatibility with existing systems and controls is a paramount consideration. As industries increasingly adopt automation and smart technologies, ensuring that the VFD motor integrates seamlessly with pre-existing equipment becomes critical. This involves evaluating communication protocols, control interfaces, and the overall architecture of the current system. Understanding the specifications and capabilities of both the new motor and the existing setup can help in achieving smooth compatibility, minimizing downtime, and ensuring operational efficiency.

Moreover, assessing the adaptability of a VFD motor to future upgrades should also be taken into account. As technology evolves, there may be a need to expand or modify existing systems. Therefore, selecting a drive that supports a range of control options and is flexible in its integration with various automation platforms is essential. An ideal choice would not only enhance current operational capabilities but also provide room for future advancements, allowing businesses to stay competitive in an ever-changing industrial landscape.

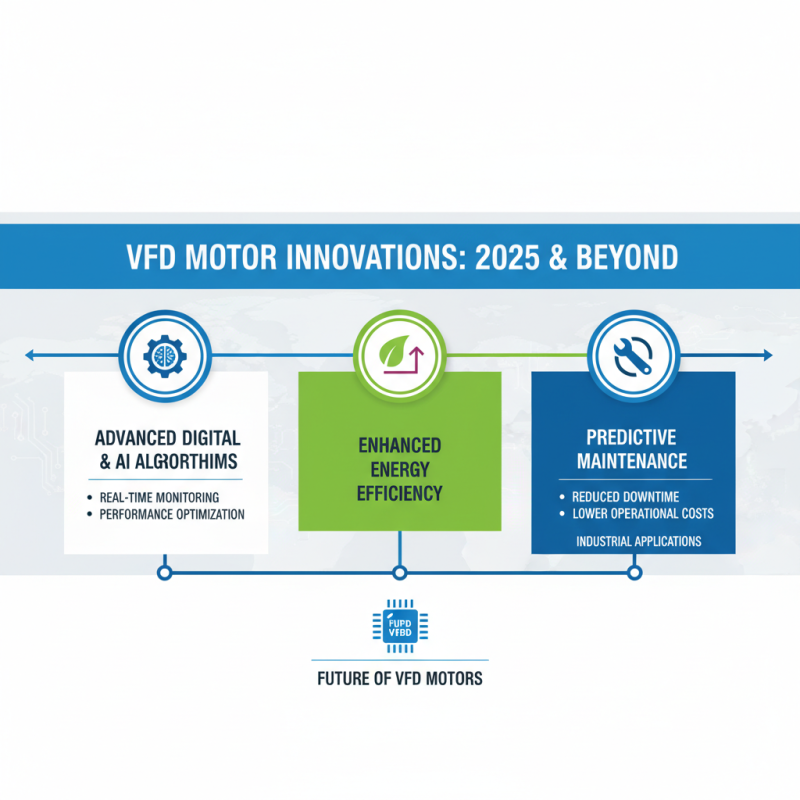

Future Trends in VFD Motors: Innovations to Anticipate in 2025

As we approach 2025, the landscape of variable frequency drive (VFD) motors is set to undergo significant transformations driven by emerging technologies and industry demands. One of the most anticipated innovations is the integration of advanced digital controls and AI algorithms, which enable real-time monitoring and optimization of motor performance. This development not only enhances energy efficiency but also allows for predictive maintenance, reducing downtime and operational costs for industrial applications.

Another trend is the shift towards increasing energy efficiency through the utilization of high-performance materials and designs. Manufacturers are expected to invest in research and development of more compact and lightweight VFD motors that offer improved thermal management and reduced energy losses. Additionally, the incorporation of IoT connectivity will facilitate seamless communication between motors and control systems, paving the way for smarter, more responsive manufacturing processes that can adapt to fluctuating demands. These advancements signify a critical step towards achieving sustainability in industrial operations while enhancing productivity and reliability.

Related Posts

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications

-

How to Choose the Right VFD Drive for Your Industrial Application

-

Top 10 Electrical Breakers for Home and Business Safety in 2023

-

What is a Motor Control Center and How Does It Improve Efficiency in Industries

-

How to Choose the Right Circuit Breakers for Your Home and Business Needs

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability