How to Choose the Right Electric Motor Controller for Your Needs?

Choosing the right electric motor controller can be daunting. With various options available, it’s essential to make informed decisions. John Smith, a leading expert in electric motor technologies, states, "The success of your electric motor lies in selecting the right controller."

When selecting an electric motor controller, consider your application's specific requirements. Factors such as voltage, current ratings, and load type significantly influence your choice. Some controllers excel in precision, while others prioritize efficiency. This balance can dictate the performance of your entire system.

However, it’s crucial to acknowledge that not all options are perfect. Many controllers have limitations. Researching and understanding these nuances can save time and resources. Look beyond specifications and consider real-world applications. Your choice should fit your operational needs, not just the technical data.

Understanding Electric Motor Controllers and Their Functions

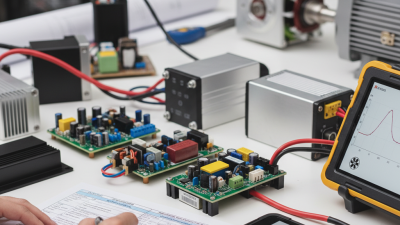

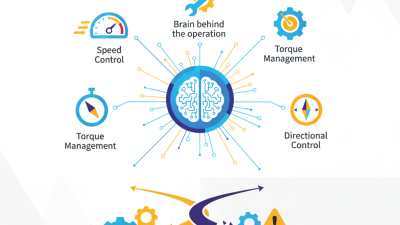

Electric motor controllers play a crucial role in various applications. They regulate the power supplied to electric motors, affecting performance and efficiency. Understanding how these controllers function can help you make informed decisions when selecting one.

When choosing a controller, consider the type of motor you are using. Different motors, such as brushed or brushless, require specific controllers. Each type has unique specifications. Check the voltage and current ratings of both the motor and controller. Mismatches can lead to inefficiencies or damage.

**Tip: Always refer to the motor's datasheet.** This document provides key details that guide your controller choice. It usually includes recommended controller specifications and performance metrics.

Moreover, assess your application requirements. Do you need precise speed control? Or is simple on/off functionality enough? Knowing these details helps narrow your options. Controllers also vary in features like regenerative braking and programmable settings.

**Tip: List your must-have features.** This way, you can easily compare different models. Don't rush; a hasty decision may lead to issues later. Consider future needs as well. Plans for more powerful motors? Select a controller with a higher capacity for scalability.

How to Choose the Right Electric Motor Controller for Your Needs?

| Controller Type | Voltage Range (V) | Current Rating (A) | Control Method | Key Features |

|---|---|---|---|---|

| Brushed DC Motor Controller | 12-48 | 10-30 | PWM | Cost-effective, easy to use |

| Brushless DC Motor Controller | 24-72 | 15-60 | FOC | High efficiency, smooth operation |

| AC Induction Motor Controller | 120-480 | 5-100 | V/f Control | Robust, suitable for industrial applications |

| Servo Motor Controller | 24-600 | 10-50 | Position control | Highly precise, feedback control |

| Step Motor Controller | 12-48 | 2-10 | Open loop | Simple, low cost, good for low precision |

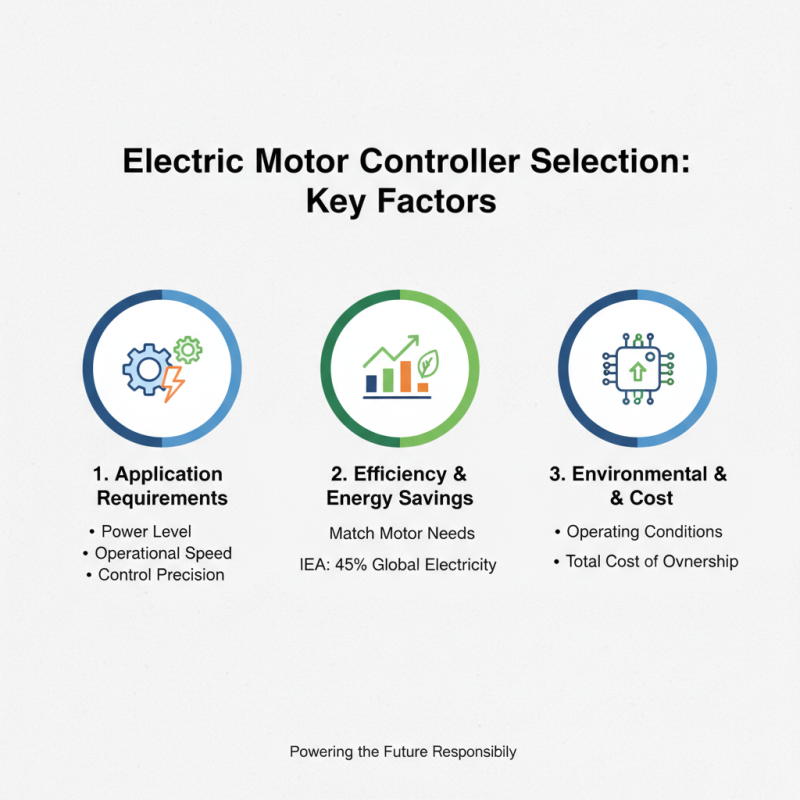

Key Factors to Consider When Choosing an Electric Motor Controller

Choosing the right electric motor controller is crucial. Several key factors influence this decision. First, consider the application requirements. Different applications demand varying power levels, operational speeds, and control precision. For instance, a report from the International Energy Agency indicates that electric motors consume about 45% of global electricity, making efficiency key. The controller you select should match the specific needs of your motor.

Next, think about compatibility. Ensure the controller aligns with your motor type. A mismatched controller can lead to inefficiency or damage. Communication protocols also matter. Many newer controllers offer advanced features like programmable logic. However, these features come with added complexity. Be wary of overhauling your system if it doesn’t truly require it. Additionally, evaluate the environmental conditions. Extreme temperatures or humidity can affect controller performance.

Lastly, reflect on the cost versus benefits. High-tech controllers may promise better efficiency but can also be expensive. A basic controller may suffice for simple tasks, while advanced systems are justified for complex applications. Demand from the electric motor market is projected to grow annually, indicating a shift towards more efficient technologies. Balancing cost, performance, and long-term goals becomes essential.

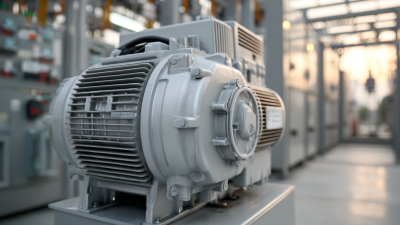

Different Types of Electric Motor Controllers: A Comparative Overview

When selecting an electric motor controller, it's essential to understand the different types available.

Brushless DC controllers are popular for their efficiency. They provide smooth operation and prolong motor life. However, they can be more complex. They require precise programming and may not suit beginners.

On the other hand, brushed motor controllers are simpler. They are often more affordable and easier to install. These controllers are ideal for basic applications. Yet, they tend to be less efficient and have shorter lifespans. Users should weigh these trade-offs carefully.

Another option is the open-loop controller. It's straightforward and works well for many applications. However, it lacks feedback mechanisms. This can lead to performance issues under varying loads. Closed-loop controllers, while more complicated, adjust based on real-time data. They offer greater precision but can be challenging to set up. Understanding these differences is crucial for making an informed choice.

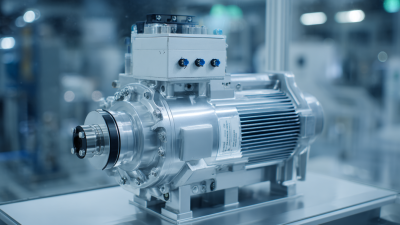

Compatibility with Motor Types: Ensuring Optimal Performance

Choosing the right electric motor controller is crucial for optimal performance. One must ensure compatibility with the specific motor type being used. Different motors, like brushed or brushless varieties, require distinct controllers. A mismatch can lead to inefficiencies, reduced lifespan, or even complete burnout of components.

Each motor type possesses unique characteristics. Brushed motors, for instance, may handle power differently than brushless motors. Understanding these differences is vital. For example, brushless motors need controllers that can effectively manage commutation. This requires specific electronic designs and programming. Sometimes, users might overlook this aspect, leading to costly repairs.

Furthermore, the controller’s voltage and current ratings must align with the motor's specifications. Careful calculations are needed here. You might consider a slightly higher rating for added safety. However, too much power could damage the system. It’s a delicate balance. Thoroughly researching each component's requirements can prevent unnecessary mistakes and ensure a smoother operation.

Evaluating Your Budget: Cost vs. Features in Motor Controllers

When considering an electric motor controller, budget plays a crucial role. According to a recent industry report, motor controller prices range widely, from $50 to over $5,000. Features such as power handling and programmability can drive costs up. Thus, understanding your specific needs is vital. Think about the necessary features before making a purchase.

Tips: Assess your project's requirements carefully. A mid-range controller might suit simple applications, while complex setups require advanced features.

Many buyers overlook long-term savings. A cheaper controller may save money now but could lead to higher energy costs later. The efficiency of the controller can greatly impact performance. The right choice balances initial cost with efficiency, performance, and durability. Prioritize features that match your application, even if they stretch your budget slightly.

Tips: Maintenance costs matter too. Some controllers may need more upkeep, affecting overall budgeting. A smart investment now can save headaches in the future.

Related Posts

-

Top 10 Electric Motor Controllers You Should Consider?

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

How to Choose the Right Electric Motor Controller for Your Project?

-

Why Do You Need an Electric Motor Controller for Your Project?

-

Exploring Electric Motor Controller Innovations at the 2025 China 138th Canton Fair

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries