2025 How to Choose the Right Electrical Switchgear for Your Needs

In today's rapidly evolving energy landscape, selecting the right electrical switchgear is crucial for ensuring both operational efficiency and safety. According to the "Global Electrical Switchgear Market Report 2023," the switchgear market is projected to grow at a CAGR of 7.1% from 2023 to 2028, driven by increasing investments in infrastructure and renewable energy projects. As more industries transition to smart grid technologies, the demand for electrical switchgear that guarantees reliability and adaptability is at an all-time high.

Experts, like Dr. Emily Torres, a leading authority in electrical engineering, emphasize the importance of making informed decisions in this domain. She states, “Choosing the right electrical switchgear is not just about meeting current needs, but also about future-proofing your operations against evolving technologies and regulations.” This highlights the need for careful consideration of various factors, including the specific application requirements, environmental conditions, and potential for future upgrades when selecting electrical switchgear.

As we move towards 2025, understanding the nuances of electrical switchgear and aligning them with your operational goals will be indispensable. This guide aims to provide insights into the key elements to evaluate, the latest technological advancements, and best practices for choosing the most suitable switchgear for your needs.

Understanding Electrical Switchgear: An Overview of Types and Functions

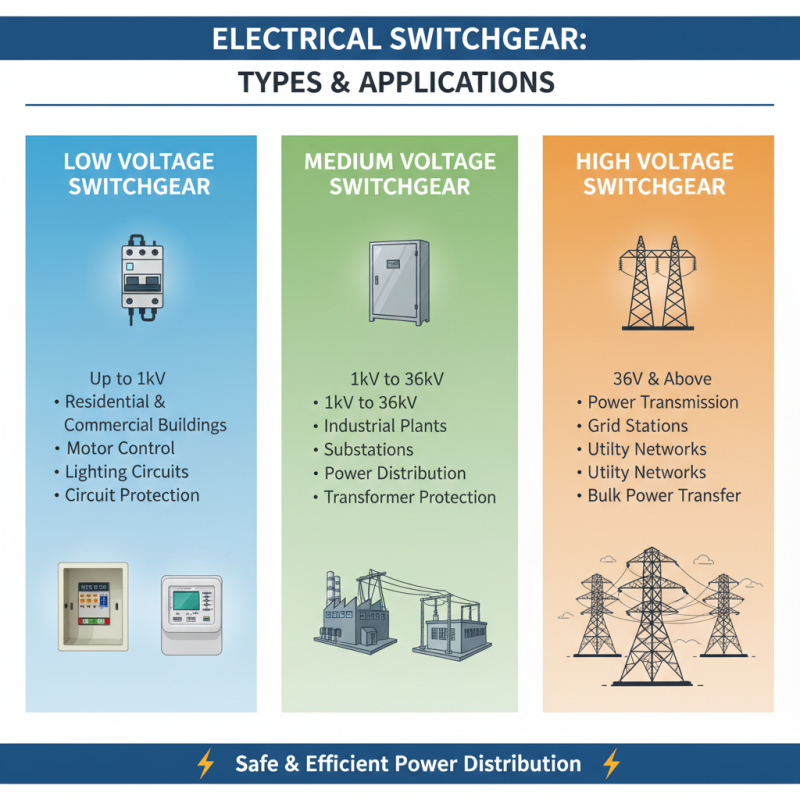

Electrical switchgear plays a crucial role in power distribution systems, serving as a vital interface between electrical sources and connected loads. Understanding the different types of switchgear is essential for selecting the right solution for your specific needs. Generally, switchgear can be categorized into three main types: low voltage, medium voltage, and high voltage switchgear. Each type is designed to operate under specific voltage levels and functionality, allowing for safe and efficient control of electrical circuits.

Low voltage switchgear is typically used in commercial and residential applications, providing protection and control for systems operating up to 1 kV. Medium voltage switchgear, on the other hand, is commonly found in industrial settings, managing voltages from 1 kV to 36 kV. It offers enhanced protection and flexibility for more extensive power distribution networks. Finally, high voltage switchgear, suitable for voltages above 36 kV, is essential in substations and large power plants, ensuring the reliable transmission of electricity over long distances.

In addition to their voltage classifications, switchgear has various functions, including circuit protection, isolation, and switching capabilities. Each type is designed with specific features to address the unique challenges of the environment in which it operates. Thus, when selecting switchgear, it is vital to evaluate the operational requirements, including voltage levels, load characteristics, and safety standards, to ensure optimal performance and reliability.

Key Factors to Consider When Selecting Electrical Switchgear

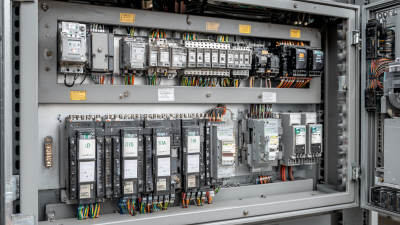

When selecting electrical switchgear, several key factors must be considered to ensure it meets your specific needs. First, assess the voltage and current ratings required for your application. This will determine the type and capacity of the switchgear, ensuring it can handle the operational demand without compromising safety or efficiency. Additionally, consider the environmental conditions, such as temperature, humidity, and the presence of dust or corrosive elements, as these factors can influence the durability and reliability of the switchgear.

Another critical aspect to evaluate is the type of protection offered by the switchgear. Look for features such as overcurrent protection, short-circuit protection, and ground fault protection, which play a vital role in safeguarding your electrical systems. It’s also important to factor in maintenance requirements; choose switchgear that allows for easy access to components while being designed for minimal maintenance to reduce operational downtime.

Finally, consider the scalability of the switchgear to accommodate future expansions or upgrades, ensuring your electrical installation remains efficient and effective as demands evolve.

Assessing Your Power Distribution Needs for Optimal Switchgear Selection

When selecting the right electrical switchgear for your needs, a thorough assessment of your power distribution requirements is crucial to ensure optimal performance and safety. According to the International Electrotechnical Commission (IEC), the global switchgear market is projected to reach USD 200 billion by 2025, highlighting the increasing importance of efficient electrical systems in various applications. Determining the specifics of your power distribution—such as load capacity, voltage level, and application zone—plays a significant role in making informed choices regarding switchgear types and configurations.

A comprehensive analysis begins with understanding your current and future load demands, which can often fluctuate. The Electric Power Research Institute (EPRI) suggests that facilities should consider not just their immediate power requirements, but also potential expansions over the next decade. This foresight helps in selecting switchgear that is not only capable of handling current loads but also adaptable to increased demands without necessitating a complete system overhaul. Furthermore, integrating smart grid technologies and predictive maintenance capabilities into your switchgear selection can enhance reliability and reduce operational costs, aligning with industry trends toward automation and efficiency.

2025 Electrical Switchgear Selection Criteria

This chart illustrates the importance of various criteria when selecting electrical switchgear for power distribution needs. The criteria include reliability, cost, safety, and efficiency, which are essential for making informed decisions for optimal switchgear selection.

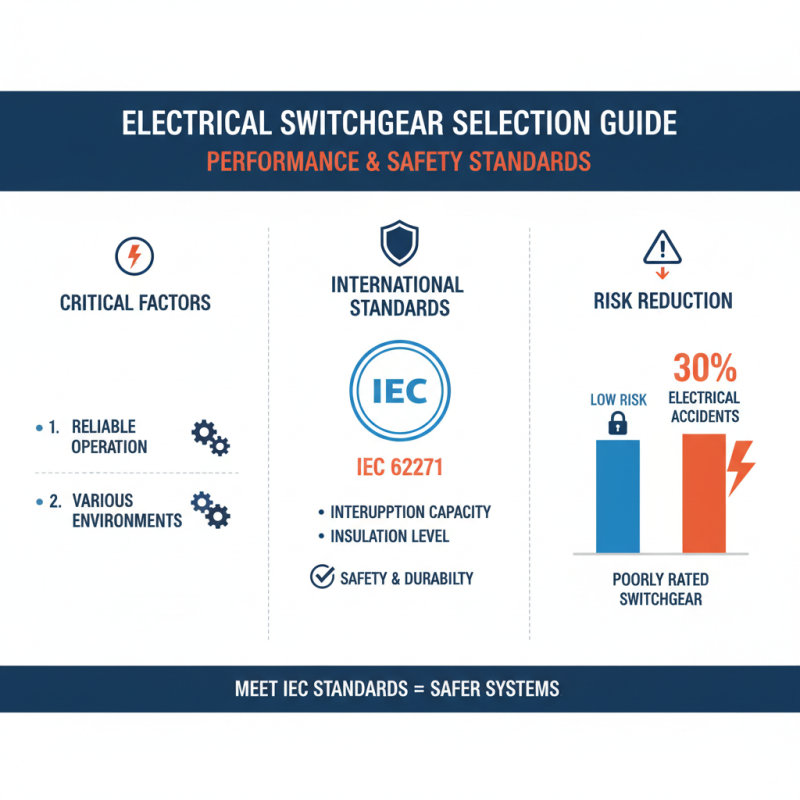

Evaluating Performance and Safety Standards in Electrical Switchgear

When selecting the appropriate electrical switchgear for your needs, evaluating performance and safety standards is critical to ensuring reliable operation in various environments. According to the International Electrotechnical Commission (IEC), switchgear must meet specific performance parameters such as interruption capacity and insulation level. The IEC 62271 standard provides detailed guidelines on the testing and operational procedures that guarantee safety and durability. Industry reports indicate that equipment adhering to these standards significantly reduces the risks of electrical failures, with poorly rated switchgear cited as the cause of nearly 30% of electrical accidents in commercial applications.

Tips: When assessing switchgear options, prioritize systems with built-in safety features like arc fault protection and overload relays. These aspects not only enhance operational safety but can also lead to higher efficiency and lower maintenance costs in the long term.

Additionally, consider the environmental conditions where the switchgear will be installed. The National Fire Protection Association (NFPA) recommends evaluating the ambient temperature, humidity, and potential exposure to corrosive substances. Switchgear designed for specific environmental conditions will outperform standard equipment, thus enhancing safety outcomes. Remember that higher safety standards often correlate with better performance metrics, reinforcing the importance of choosing rightly.

Budgeting for Your Electrical Switchgear: Cost vs. Quality Considerations

When budgeting for electrical switchgear, it’s crucial to weigh the balance between cost and quality. While it may be tempting to opt for the cheapest option available, this approach can lead to increased expenses in the long run due to potential failures, maintenance costs, and operational inefficiencies. High-quality switchgear is often designed to meet rigorous safety standards and provide reliable performance, which can be particularly important in critical applications where downtime is not an option.

Understanding your specific needs plays a vital role in this decision-making process. Assessing factors such as the electrical load, environmental conditions, and future expansion plans can help in selecting switchgear that not only fits your budget but also satisfies long-term operational requirements. Investing slightly more upfront for quality equipment may save significant costs related to repairs, replacements, or operational issues in the future. Therefore, a detailed evaluation of both initial costs and potential ongoing expenses will help you make an informed decision that aligns with your financial and operational goals.

2025 How to Choose the Right Electrical Switchgear for Your Needs - Budgeting for Your Electrical Switchgear: Cost vs. Quality Considerations

| Feature | Importance | Cost Range (USD) | Quality Rating (1-5) |

|---|---|---|---|

| Voltage Rating | High | $500 - $2000 | 5 |

| Current Rating | High | $300 - $1500 | 4 |

| Insulation Type | Medium | $200 - $800 | 4 |

| Installation Complexity | Medium | $1000 - $3000 | 3 |

| Maintenance Requirements | High | $150 - $600 | 5 |

| Environmental Rating | High | $400 - $1200 | 4 |

Related Posts

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs

-

Why Motor and Control Solutions Are Essential for Modern Automation Systems

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Why Are Electric Motors Essential for Modern Technology and Industry?

-

Top Strategies for Maximizing Efficiency with Electrical Switch Innovations