How to Choose the Right VFD Drive for Your Industrial Application

In the realm of industrial automation, selecting the appropriate Variable Frequency Drive (VFD drive) is pivotal for optimizing performance and energy efficiency. According to John Smith, a renowned expert in the field of motor control systems, "Choosing the right VFD drive can significantly enhance the operational efficiency of industrial processes." This statement underscores the importance of understanding the specific requirements of your application before making a selection.

The process of selecting a VFD drive involves various considerations, including the type of motor, load characteristics, and the operational environment. A well-chosen VFD drive not only improves energy consumption but also prolongs equipment lifespan and reduces maintenance costs. Therefore, it is crucial for engineers and decision-makers to be well-informed about the available options and their functionalities.

Furthermore, with the continued advancement of technology, the capabilities of VFD drives are expanding, making them more adaptable to different industrial needs. By delving into the nuances of VFD drive selection, businesses can ensure they are not only meeting their current demands but are also prepared for future innovations in automation and efficiency.

Understanding the Basics of VFD Drives and Their Applications

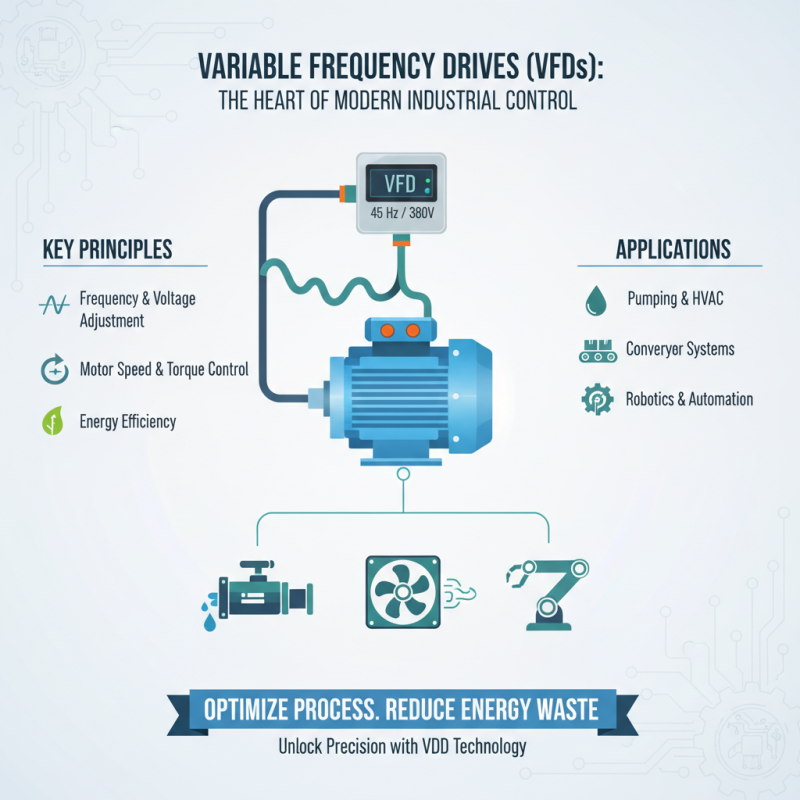

Variable Frequency Drives (VFDs) are essential components in modern industrial applications, allowing for precise control over the speed and torque of electric motors. Understanding the fundamentals of VFD technology is critical for selecting the appropriate drive for specific industrial needs. A VFD operates by adjusting the frequency and voltage supplied to the motor, resulting in efficient energy usage and improved process control. This adaptability makes VFDs suitable for a wide range of applications, from pumping and HVAC systems to conveyor belts and robotics.

When considering the application of VFDs, it is important to evaluate the motor's requirements and the operational environment. Factors such as load type, starting torque, and environment conditions play significant roles in determining the best fit. For instance, applications with variable loads can benefit significantly from VFDs, as they can smoothly adjust speeds to match the operational demands, optimizing performance and energy consumption. Additionally, understanding the specific features and capabilities of different VFDs, such as communication interfaces and control algorithms, can enhance their effectiveness in meeting the unique needs of each industrial application.

Key Factors to Consider When Choosing a VFD Drive

When selecting the right Variable Frequency Drive (VFD) for your industrial application, it’s essential to consider several key factors to ensure optimal performance. One of the primary considerations is the motor type and power requirements. VFDs must be compatible with the specific motor, whether it's an AC or DC motor, and should match or exceed the motor's power rating. This ensures efficient operation and prevents overload situations that could damage both the drive and the motor.

Another critical factor is the application environment. Assess whether the VFD will be used in a harsh environment, such as one with ambient temperature extremes, dust, or moisture. In such cases, opting for a VFD with enhanced protective features, such as conformal coatings or superior heat dissipation, can be beneficial. Additionally, considering the operational settings, such as the frequency range and control modes (like V/f control or sensorless vector control), is vital for applications requiring precision speed control.

Tips: Always review the manufacturer's specifications and guidelines carefully. Understanding the maximum load conditions and how the VFD will interact with other equipment in your system can prevent future operational issues. Furthermore, considering the ease of integration and programming features can save time during installation and ensure that your team can quickly adapt to the new system.

Assessing the Power Requirements for Your Industrial Equipment

When choosing the right Variable Frequency Drive (VFD) for your industrial application, assessing the power requirements of your equipment is paramount. This process begins by evaluating the motor specifications, including voltage, current ratings, and horsepower. Understanding the operational conditions, such as load variations and duty cycles, will allow for a more precise match between the VFD and the motor. Accurately calculating the required power not only helps in selecting a suitable VFD but also ensures optimal performance and longevity of both the drive and the motor.

Additionally, consideration should be given to the start-up requirements of the application. Certain loads may demand higher inrush currents, which can affect the selection of a VFD. It's crucial to assess whether the VFD can handle these demands without compromising efficiency. Furthermore, elements such as ambient temperature and installation conditions should be taken into account, as they can influence the performance of the drive. By carefully assessing these power requirements, one can ensure a well-matched VFD that enhances operational efficiency and reliability in industrial settings.

Power Requirements for Different Industrial Equipment

Evaluating Environment and Compatibility for VFD Installation

When selecting a Variable Frequency Drive (VFD) for industrial applications, evaluating the environment and compatibility is crucial for ensuring optimal performance and longevity. The environmental factors include both the physical surroundings—such as temperature, humidity, and exposure to dust or chemicals—and the electrical conditions, such as voltage stability and harmonics in the power supply. According to a report by the National Electrical Manufacturers Association (NEMA), approximately 30% of drive failures can be attributed to improper environmental conditions, emphasizing the need for a thorough assessment. For instance, if a VFD is installed in an area with high ambient temperatures or in a corrosive atmosphere, it's essential to choose a drive that offers adequate cooling and protective features tailored to those specific conditions.

Compatibility with existing systems is equally important. Assessing how the VFD integrates with motors and control systems ensures seamless communication and efficiency. Choosing a drive that accommodates the specific motor type, such as induction or synchronous motors, can significantly impact operational efficiency. Additionally, a 2021 market research report by MarketsandMarkets highlighted that nearly 40% of industries cite interoperability issues as a major challenge when upgrading or installing VFDs. To mitigate these risks, it is advisable to conduct compatibility tests and rely on standardized communication protocols to enhance the integration process, ultimately leading to improved performance and reduced downtime in industrial applications.

How to Choose the Right VFD Drive for Your Industrial Application - Evaluating Environment and Compatibility for VFD Installation

| Criteria | Description | Considerations |

|---|---|---|

| Operating Environment | Assess the conditions where the VFD will be installed (temperature, humidity, dust). | Choose IP rating, over-temperature protection, and ensure compatibility with ambient conditions. |

| Load Type | Identify whether the load is constant torque, variable torque, or special applications. | Select VFD that matches the specific torque and speed requirements. |

| Power Supply Conditions | Understand the type of power supply (single-phase or three-phase, voltage levels). | Ensure the VFD rating is compatible with the electrical supply available. |

| Integration with Existing Systems | Evaluate how the VFD will integrate with current control systems and machinery. | Check for compatibility with communication protocols and control systems. |

| Regulatory and Standards Compliance | Identify applicable industry standards and regulatory requirements. | Ensure VFD meets necessary certifications and compliance standards. |

| Future Expansion | Consider future scalability and potential for additional loads. | Select VFD with capacity for future applications and easy scalability. |

Analyzing Energy Efficiency Standards and Their Impact on Selection

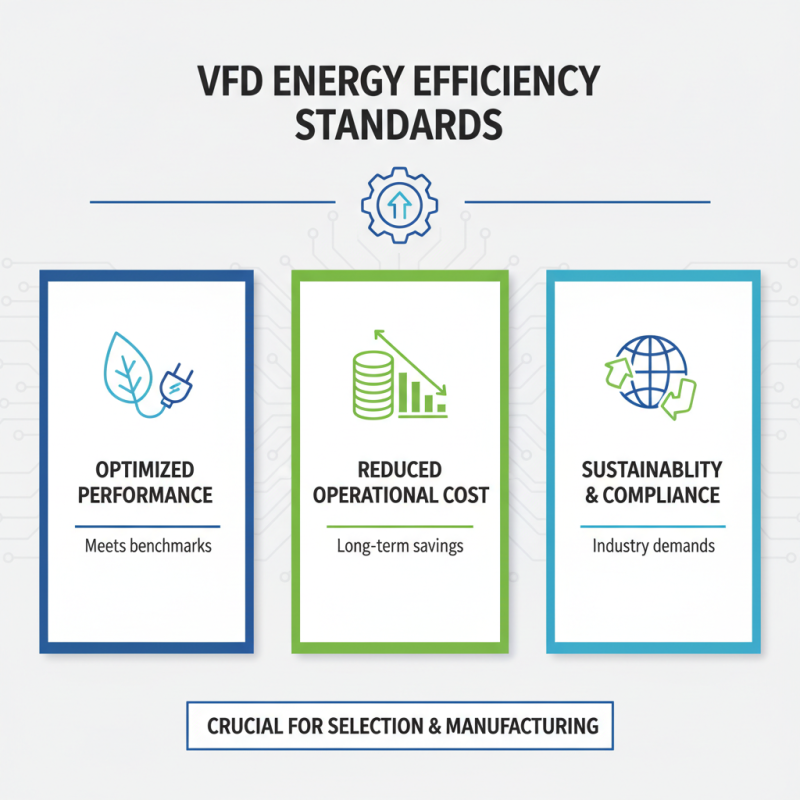

When selecting a Variable Frequency Drive (VFD) for industrial applications, understanding energy efficiency standards is paramount. These standards not only dictate the performance benchmarks that drives must meet but also influence their long-term operational costs. The adherence to established energy efficiency protocols ensures that the VFD functionality aligns with industry demands for sustainability, making it crucial for manufacturers to appreciate the ramifications of these rules during the selection process.

The impact of energy efficiency standards can significantly affect the choice of VFDs. Higher efficiency ratings generally translate to reduced energy consumption, which is a vital element in operating budgets for many industrial operations. Furthermore, selecting VFDs that comply with these standards can potentially qualify facilities for government incentives or rebates, offering a financial benefit alongside improved operational performance. It is essential for decision-makers to analyze both the initial investment and the potential savings over time when evaluating VFD options that align with the latest energy efficiency directives.

Related Posts

-

Understanding the Benefits of VFD Drive Technology in Modern Industries

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions

-

Top Benefits of Variable Frequency Motor Controllers for Efficient Energy Use

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters