How to Choose the Right VFD Drive for Your Industrial Applications?

Choosing the right VFD drive for industrial applications can be challenging. A Variable Frequency Drive (VFD) optimizes motor performance and energy efficiency. However, the selection process involves various factors.

Consider the application type. Different industries have unique requirements. Factors like load type, power rating, and operational environment must be evaluated. A VFD drive that works well in one setting may not be suitable for another.

Reflect on compatibility as well. The VFD drive should match the motor type and existing control systems. Poor compatibility can lead to inefficiencies. Taking the time to analyze these aspects can prevent costly mistakes. Finding the perfect match is not always straightforward, but it is crucial for optimal performance.

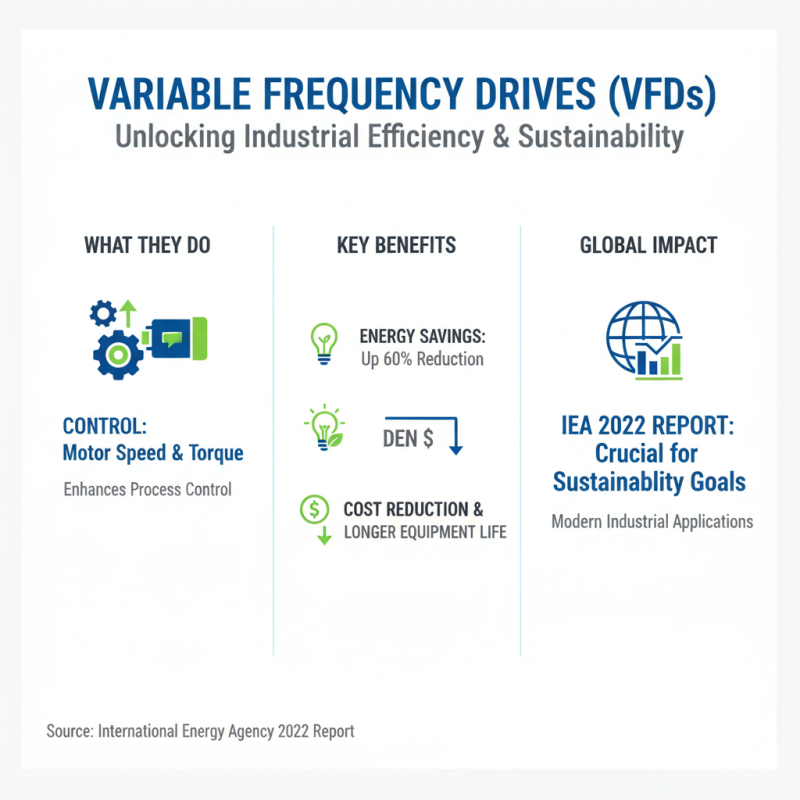

Understanding VFD Drives and Their Importance in Industrial Applications

Understanding Variable Frequency Drives (VFDs) is crucial for modern industrial applications. These devices control the speed and torque of electric motors, enhancing efficiency and reducing energy consumption. According to a 2022 report by the International Energy Agency, VFDs can decrease energy usage by up to 60% in various industrial processes. This is significant in a world striving for sustainability.

Choosing the right VFD is not straightforward. Factors such as the type of load and operational requirements significantly influence choices. For instance, a centrifugal pump operates differently than a conveyor system. Some organizations overlook these vital distinctions, leading to less efficient systems. Additionally, the complexity of VFDs can be daunting. Proper training is often needed to ensure optimal use.

Many users report issues with overheating or incorrect settings. This can lead to unexpected downtime. So, awareness of these pitfalls is essential. Industrial facilities must focus on careful selection and regular maintenance. This ensures long-term reliability. The technology is powerful, but it requires an understanding of its capabilities and limitations. Making informed adjustments can significantly enhance performance.

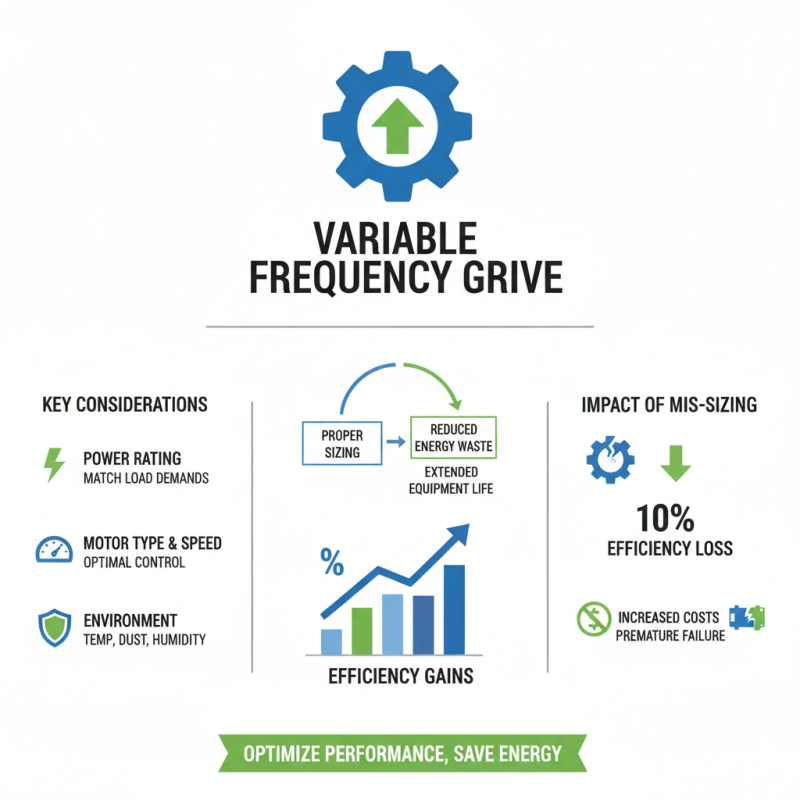

Identifying the Key Factors for Selecting a VFD Drive

When selecting a Variable Frequency Drive (VFD) for industrial applications, it’s essential to address several key factors. Begin with determining your motor specifications. Look at the power rating and voltage. Know the operational environment. Some locations can be harsh, affecting equipment longevity.

Consider the control method needed for your application. Will you require a simple control, or something more sophisticated? Understanding these needs can eliminate unsuitable options. It’s also important to evaluate your energy efficiency goals. Are you seeking ways to reduce costs? A higher efficiency drive can significantly lower energy consumption but may come at a higher upfront cost.

Finally, think about future scalability. Your needs may evolve over time. The chosen drive should accommodate upgrades or additional features later on. Make sure the documentation and support are readily available. These are aspects that can often be overlooked, leading to potential challenges down the line. Balancing all these factors can lead to a more informed selection process.

Comparing Different Types of VFD Drives and Their Applications

When selecting a Variable Frequency Drive (VFD) for industrial applications, consider the type that fits best. There are several types of VFDs, each designed for specific needs. For instance, sine wave drives are efficient for general motors, while PWM drives provide greater control for sensitive machinery. Identifying the primary requirement is crucial.

Tips: Assess the load characteristics before deciding. Knowing if the application requires torque control or speed regulation will guide you toward the right choice. This information can often be overlooked.

For complex applications, vector control drives are ideal. They offer precision, especially where speed stability is vital. However, these may require more intricate setups and tuning. Ensure your team possesses the necessary expertise.

Tips: Always review the environment where the VFD will operate. Factors like temperature, humidity, and dust can affect performance. A drive suited for a clean, controlled space may falter in a harsher setting.

Keep in mind, your initial choice may not always be perfect. Regularly evaluate the system's performance. Sometimes, minor adjustments can vastly improve efficiency and reliability.

Evaluating Technical Specifications: Power Rating, Voltage, and Control Methods

When selecting a Variable Frequency Drive (VFD) for industrial applications, understanding technical specifications is crucial. The power rating of a VFD directly affects its efficiency and performance. For instance, a report from the Electric Power Research Institute states that systems can lose up to 10% efficiency if the power rating is inadequate. Proper sizing ensures optimal operation, reducing energy waste.

Voltage compatibility is another critical factor. Many industrial settings operate at different voltage levels. A mismatch can lead to significant damage or inefficient performance. A study revealed that 30% of VFD failures are related to voltage issues. Thus, it’s vital to choose a drive that matches your facility's electrical specifications.

Control methods also play a role. VFDs can utilize various control strategies, such as scalar control or vector control. Scalar control is simpler but less efficient, while vector control offers better precision and control. However, vector control systems can be more complex and costly. Balancing these factors requires careful consideration to ensure that the chosen VFD meets specific operational needs. In this evolving landscape, the right choice can influence productivity and operational costs drastically.

Implementing Maintenance and Troubleshooting Tips for VFD Drives

VFD drives are crucial in many industrial settings. However, they can face issues requiring regular maintenance and troubleshooting. Knowing how to identify these problems can minimize downtime and save costs.

One common problem is overheating. Ensure that the drive is adequately ventilated. Check for obstructions near cooling fans. Dirty filters can also lead to overheating. Cleaning these regularly is vital.

Another frequent issue is electrical noise. This can affect performance and reliability. Using proper grounding and shielding for your drive can help reduce noise.

If you notice unusual vibrations, it could be a sign of misalignment. Perform regular checks on the motor and load. Look for any mechanical wear or damage. Addressing these issues early can prevent bigger problems. Maintain a log of maintenance activities. This can help identify patterns in failures and improve the overall reliability of your VFD drives. Regular reviews of performance data can guide more effective maintenance strategies, making your systems run smoother.

Related Posts

-

Understanding the Benefits of VFD Drive Technology in Modern Industries

-

How to Choose the Right VFD Drive for Your Industrial Application

-

Best VFD Drive for Energy Efficiency and Performance in Industrial Applications

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Top 10 Essential Tips for Choosing the Perfect Electrical Switch

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters