How to Choose the Right VFD Electrical System for Your Needs?

Choosing the right VFD electrical system is crucial for optimizing performance. According to Dr. Emily Hayes, a renowned expert in the VFD electrical industry, "Selecting the right VFD system can significantly enhance energy efficiency." This highlights the importance of making informed decisions.

When exploring VFD electrical options, consider your specific needs. Take into account the motor type and load conditions. For example, a system designed for a variable load might differ from one suited for constant loads. Look for features like energy savings, control precision, and compatibility with existing systems.

However, it’s easy to overlook critical details. Many users focus solely on initial costs. Sometimes, cheaper options can lead to higher operating costs over time. Reflecting on your choices can lead to better long-term performance and savings. Emphasizing careful selection in the VFD electrical sector can yield positive results in efficiency and reliability.

Understanding VFDs: What They Are and How They Work

Variable Frequency Drives (VFDs) are crucial in modern electrical systems. They control motor speed and torque by varying the input frequency and voltage. This flexibility improves energy efficiency. Reports from the U.S. Department of Energy suggest that using VFDs can save up to 50% of energy in certain applications.

Understanding how VFDs work is essential. They use a process called pulse-width modulation to convert AC to DC, then back to AC at a different frequency. This method allows precise control over motor operations. Many industries have adopted VFD technology, resulting in smoother operations and reduced mechanical stress on equipment.

**Tips**: Consider your specific application needs. Evaluate the motor type, voltage, and required control features. Sometimes, VFDs can be overly complex for simpler tasks. Ensure you balance functionality with your operational requirements.

Another point to reflect on is installation. Improper installation can lead to inefficiencies and equipment issues. It's vital to consult experts during the setup process. Little mistakes can lead to costly repairs down the line. Always plan before you implement.

Understanding VFD Electrical Systems: Key Factors

This bar chart illustrates key specifications of Variable Frequency Drives (VFDs) important for selecting the right electrical system. Consider power rating, efficiency, torque, frequency range, and control method to meet your specific needs.

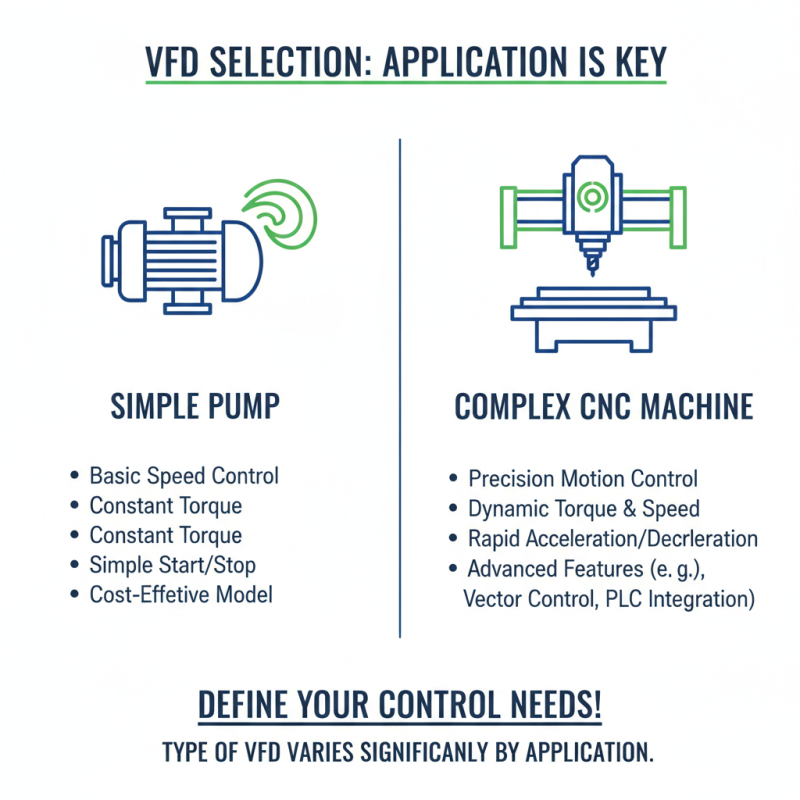

Identifying Your Application Needs for VFD Selection

When selecting a Variable Frequency Drive (VFD) electrical system, understanding your specific application needs is crucial. Each application can vary significantly, impacting the type of VFD suitable for your operation. For example, if you’re controlling a simple pump, your requirements differ vastly from those needed for a complex CNC machine. It's essential to clearly define what control features you need.

Consider the load type: is it constant or variable? Pulsating loads may require a different approach than steady-state loads. Pay attention to the motor size as well. A 5 HP motor and a 100 HP motor will demand different VFD specifications. It’s also important to reflect on environmental factors like temperature and humidity. These factors can influence performance and operational efficiency.

Do not overlook communication requirements either. How will the VFD integrate with your existing systems? Compatibility can be a challenge. You may even find yourself adjusting your initial choices after testing. There’s often a learning curve with VFD systems. Being flexible can lead to better long-term outcomes. Always think critically about your needs. The right choice is rarely one-size-fits-all.

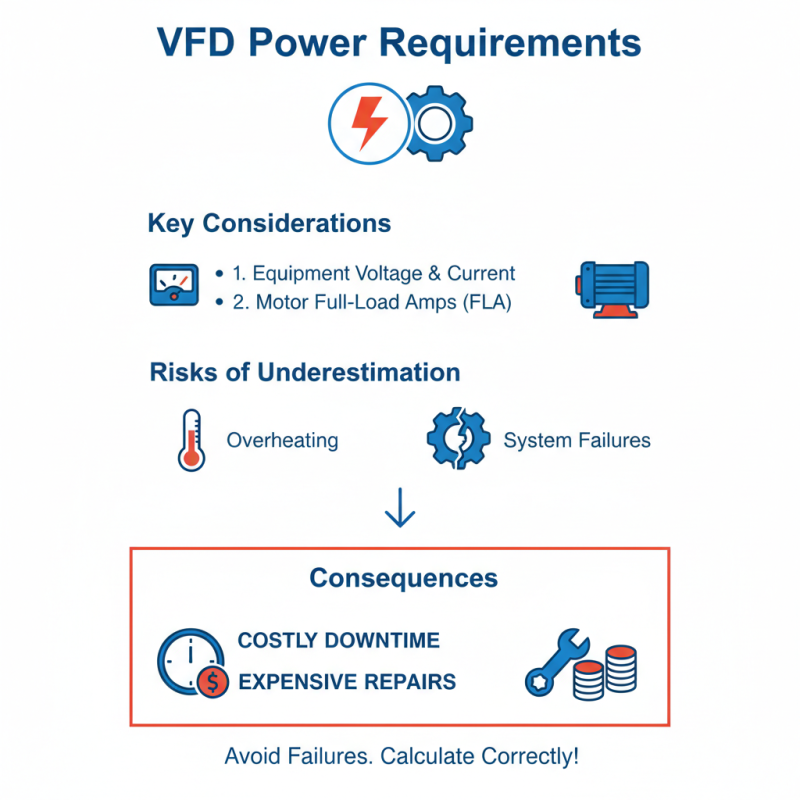

Evaluating Power Requirements and Compatibility Considerations

When evaluating power requirements for a Variable Frequency Drive (VFD) system, consider your equipment's voltage and current needs. Determine the full-load amps of your motor to ensure compatibility. If you underestimate these needs, you may experience overheating or system failures. This often leads to costly downtime and repairs, something every operator fears.

It's also important to check how the VFD integrates with your existing electrical setup. Different VFDs have specific requirements for installation. For example, they may demand separate circuits or additional protective devices. This can complicate installation and increase costs. Evaluate the wiring and circuit breakers in use. If they don’t match, adjustments are essential.

Consider consulting with a professional if you're uncertain. Their insights can prevent missteps. VFD systems can enhance efficiency greatly, but choosing incorrectly may yield performance issues. A careful assessment of power and compatibility can guide you in selecting the right system. Exploring the specifications thoroughly can save future trouble. It's easy to overlook details, but being thorough now will aid in decision-making later.

Exploring Control Options and Features in VFD Systems

When choosing a Variable Frequency Drive (VFD) system, control options and features play a crucial role. Different applications require different control methods. For instance, scalar control is simple but offers limited performance. On the other hand, vector control provides better torque and speed. However, it can be more complicated to configure.

Another essential feature is the communication protocols. Some systems offer more connectivity options than others. This can be a game-changer in how you integrate your VFD with existing equipment. It affects your ability to monitor operations in real time. Manufacturers might boast about easy integration, but users often find that setup is more complex than advertised.

Finally, consider the user interface. A well-designed interface can make operation and troubleshooting much easier. Users often report frustration with confusing displays or menus. It's crucial to evaluate how intuitive the system is. A complicated interface may lead to errors or downtime. Reflect on past experiences where ease of use has made a difference in productivity.

Assessing Budget and Cost-Benefit Analysis for VFD Solutions

When assessing the budget for a Variable Frequency Drive (VFD) electrical system, several factors come into play. Consider initial investment costs, including purchasing and installation expenses. It's crucial to evaluate ongoing operational costs as well. Electricity savings can be significant, but they often depend on usage frequency and specific applications.

Another aspect to analyze is the cost-benefit ratio. Determine how much energy the VFD can save over time. A detailed calculation can show potential returns on investment. Sometimes, the upfront costs may seem high, but long-term savings could justify the expense. It's important to identify if the expected savings align with your financial goals.

In practice, some users may overlook maintenance costs in their assessments. Regular upkeep can add to expenses but is vital for efficient operation. Budgeting for potential repairs or upgrades is also wise. Reflect on your unique requirements and existing systems. Are you fully aware of the true financial impact?

Related Posts

-

How to Choose the Right VFD Drive for Your Industrial Applications?

-

How to Choose the Right Circuit Breakers for Your Home Electrical System

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications

-

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

Exploring the Future: Motor Starters at the 138th Canton Fair 2025 and Industry Trends