Why Are Electric Motors Essential for Modern Technology and Industry?

Electric motors have become a cornerstone of modern technology and industry, driving innovation and efficiency across various sectors. As noted by renowned electrical engineer Dr. Emily Carter, "Electric motors are the heartbeat of contemporary manufacturing and transportation systems, enabling unparalleled performance and sustainability." This insight encapsulates the profound impact that electric motors have on our daily lives and economic structures.

In the realm of industrial applications, electric motors facilitate precise control and reliability, contributing to the automation and efficiency of production processes. From powering conveyor belts in factories to driving high-speed trains, the versatility of electric motors allows for the seamless operation of complex machinery. Moreover, with the increasing emphasis on renewable energy sources and reduced carbon footprints, electric motors present a cleaner alternative to traditional combustion engines, underscoring their critical role in the transition towards a more sustainable future.

Furthermore, in consumer technology, electric motors enable the functioning of a myriad of devices, from household appliances to electric vehicles. Their significance is not confined to industrial applications; instead, they permeate various facets of our lives, influencing everything from how we commute to how we interact with everyday technologies. As we continue to innovate and integrate electric motors into new applications, their essential role in shaping a more advanced and sustainable world cannot be overstated.

Importance of Electric Motors in Modern Transportation Systems

Electric motors play a pivotal role in modern transportation systems, significantly transforming how we move people and goods. From electric cars to trains and public transit, these motors provide an eco-friendly alternative to traditional combustion engines. They are not only more efficient but also produce fewer emissions, thus contributing to a reduction in air pollution and greenhouse gas emissions. As cities expand and the demand for sustainable transport grows, electric motors prove to be crucial in developing smart, green transportation networks.

Tips for maximizing the benefits of electric motors in transportation include investing in infrastructure that supports charging stations, encouraging the adoption of electric vehicles through incentives, and prioritizing research into improving battery technology. Furthermore, incorporating electric motors in public transportation systems enhances reliability while reducing maintenance costs, leading to an overall better commuting experience for all.

As technology continues to advance, the integration of electric motors into maritime and aviation industries is also being explored. This shift promises to revolutionize logistics and travel by providing quieter, more efficient, and environmentally friendly alternatives. With ongoing innovations, the impact of electric motors on transportation will only continue to grow, making them an essential element of our modern infrastructure.

Importance of Electric Motors in Modern Transportation Systems

Role of Electric Motors in Industrial Automation and Robotics

Electric motors play a pivotal role in industrial automation and robotics, serving as the driving force behind a myriad of processes that define modern manufacturing. In automated systems, electric motors are responsible for precise movements and efficient operation of machinery, enabling tasks such as assembly, material handling, and packaging to be carried out with speed and accuracy. Their ability to provide consistent torque and speed control is essential for maintaining production line efficiency, reducing downtime, and improving overall productivity.

In the realm of robotics, electric motors are crucial for enabling complex movements and functions. They facilitate the articulation of robotic arms and actuators that are essential for tasks ranging from simple pick-and-place operations to intricate assembly processes. The compact size and versatility of electric motors allow for flexible designs in robotic systems, making them suitable for various applications in sectors such as automotive, electronics, and pharmaceuticals. Moreover, advancements in motor technology, such as brushless designs and improved energy efficiency, continue to enhance the performance and reliability of robots, further solidifying their importance in contemporary industry.

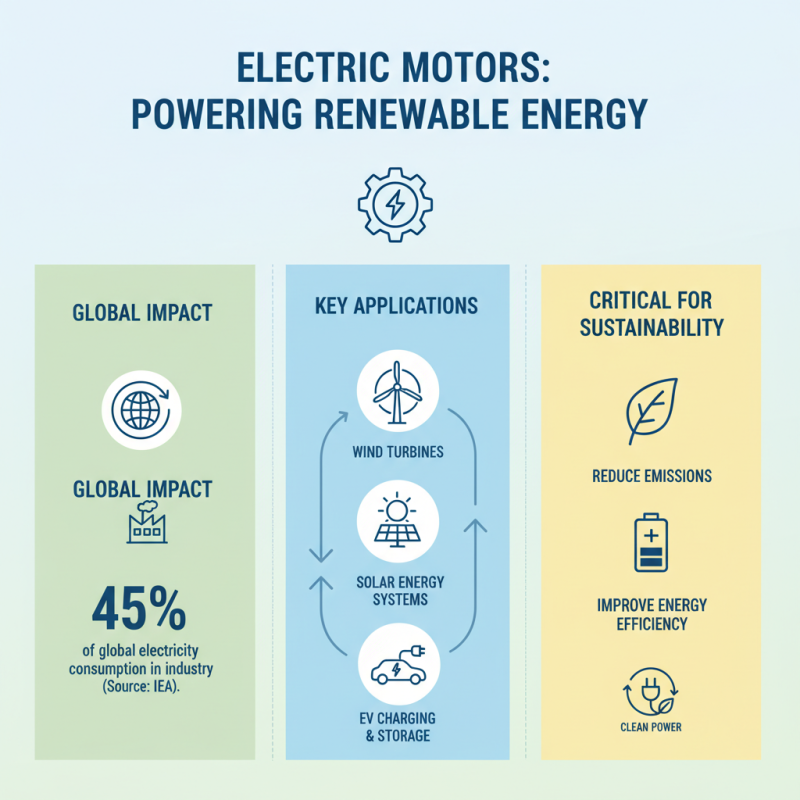

Impact of Electric Motors on Renewable Energy Solutions

Electric motors are critical components in advancing renewable energy technologies, acting as the backbone for various applications ranging from wind turbines to solar energy systems. According to a report by the International Energy Agency (IEA), electric motors are responsible for around 45% of global electricity consumption in industrial settings, highlighting their widespread use and importance. As the world shifts towards more sustainable energy sources, the efficiency and performance of electric motors become more paramount, particularly in reducing emissions and improving energy use in sectors that depend on renewable sources.

The integration of electric motors into renewable energy solutions significantly enhances their effectiveness. For example, wind turbines employ electric motors in their generators to convert mechanical energy into electrical energy with minimal losses. The Global Wind Energy Council (GWEC) noted that the total installed wind power capacity reached 743 GW globally in 2020, showcasing the importance of efficient motor technology in this scaling process. Additionally, advancements in electric motors have led to increased energy efficiency, which can improve the overall output of renewable energy installations. The U.S. Department of Energy estimates that optimizing motor systems can save more than $4 billion annually in energy costs, underscoring the role electric motors play in making renewable solutions more economically viable and environmentally friendly.

Applications of Electric Motors in Consumer Electronics and Appliances

Electric motors play a fundamental role in the function and success of consumer electronics and appliances, driving innovation and efficiency in homes and workplaces. From the small motors in household gadgets to larger systems in major appliances, these motors convert electrical energy into mechanical motion, enabling devices to perform tasks with precision and speed. Common applications include washing machines that rely on electric motors to agitate and spin laundry, refrigerators equipped with compressors to maintain optimal temperatures, and vacuum cleaners that utilize high-speed motors to create powerful suction.

In addition to traditional appliances, electric motors are widely used in various consumer electronics, enhancing user experience and functionality. For instance, in computers and mobile devices, motors enable cooling fans that dissipate heat and prevent overheating, ensuring optimal performance. Furthermore, electric motors are integral in electric vehicles, powering essential systems from windows to wipers and contributing to the overall efficiency of the vehicle. As technology continues to evolve, the reliance on electric motors is set to increase, making them essential components in creating smarter, more efficient living environments.

Why Are Electric Motors Essential for Modern Technology and Industry? - Applications of Electric Motors in Consumer Electronics and Appliances

| Application | Motor Type | Power (W) | Efficiency (%) |

|---|---|---|---|

| Washing Machines | Brushless DC Motor | 500 - 1500 | 85 - 90 |

| Electric Vehicles | AC Induction Motor | 50,000 - 100,000 | 90 - 95 |

| Refrigerators | Compressor Motor | 100 - 500 | 75 - 80 |

| Air Conditioners | Single-phase Motor | 500 - 3000 | 80 - 85 |

| Fans | AC Motor | 20 - 100 | 70 - 75 |

Future Trends and Innovations in Electric Motor Technology

The evolution of electric motor technology is set to redefine numerous industries, driven by advancements in efficiency, sustainability, and integration with smart technologies. Recent reports from the International Energy Agency (IEA) projected that electric motors could save over 6,500 terawatt-hours of electricity by 2040, a significant reduction in energy consumption that would simultaneously cut global carbon emissions. As industries push for greener practices, innovations such as magnetic levitation (maglev) motors and digitally enhanced control systems are paving the way for high-performance applications in transportation, manufacturing, and robotics.

Tips for businesses considering the adoption of new electric motor technologies include evaluating the lifecycle costs of various motor types and considering energy efficiency ratings. Investing in high-efficiency motors can not only reduce operational expenses but also align with regulatory standards aimed at reducing carbon footprints. Additionally, companies should stay informed about breakthroughs in integration with smart technology, which enable real-time monitoring and predictive maintenance, ultimately increasing productivity.

With the rise of Industry 4.0, electric motor innovations are becoming more intertwined with internet-of-things (IoT) applications. This integration leads to smarter factories that optimize production lines and energy usage through data-driven insights. Industries that embrace these trends will not only become more competitive but also contribute significantly to a sustainable future. The ongoing research and development in motor materials, such as superconductors, may also lead to lighter, more efficient designs, drastically changing the landscape of electric motor applications across various sectors.

Related Posts

-

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Exploring Electric Motors Innovations at the 2025 China Import and Export Fair

-

The Future of Electric Motors: Innovations Driving the Next Generation of Sustainable Technology

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits

-

Understanding the Role of 3 Phase Electric Motors in Modern Industrial Applications