What is Electrical Switchgear and How Does it Work?

Electrical switchgear is a critical component in power systems. It acts as the control hub for electrical energy distribution. Understanding its function is essential for engineers and technicians.

This equipment includes various devices that manage and protect electrical circuits. It ensures the safe operation of electrical systems. Switchgear facilitates the isolation of faults and enables maintenance without disrupting power supply.

However, many overlook the importance of proper maintenance. Neglect can lead to failures and safety hazards. Regular inspections and updates are vital to ensure reliability. By grasping the role of electrical switchgear, professionals can enhance operational efficiency and safety.

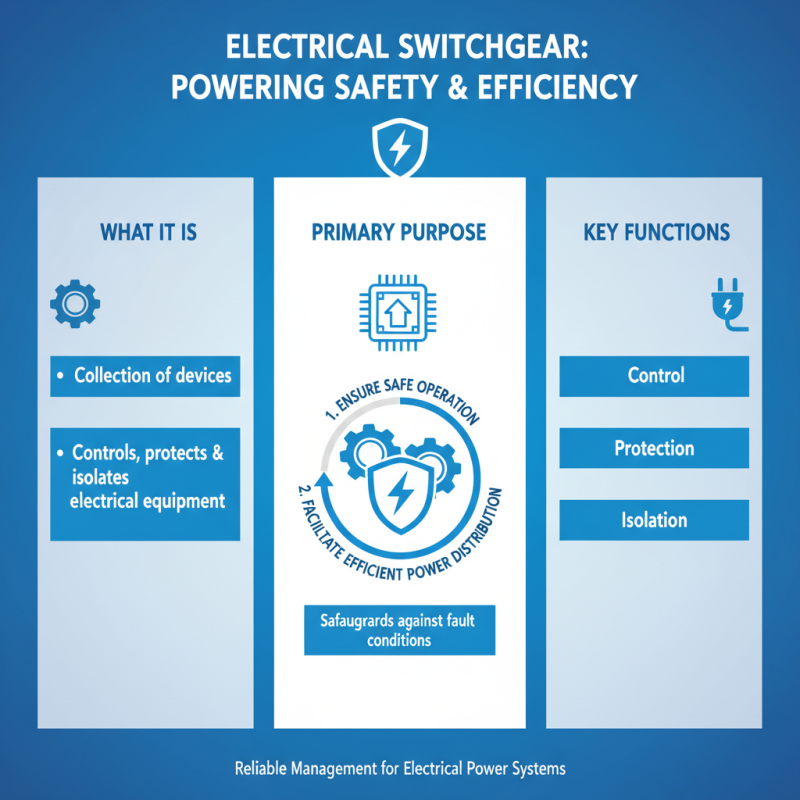

Definition and Purpose of Electrical Switchgear

Electrical switchgear is crucial in managing electrical power systems. It includes various devices that control, protect, and isolate electrical equipment. The primary purpose of switchgear is to ensure that electrical systems operate safely and efficiently. It acts as a safeguard against fault conditions and helps to manage power distribution.

These devices come in different forms, such as circuit breakers, fuses, and contactors. Each component plays a specific role in controlling voltage and current flow. For instance, circuit breakers can automatically shut off power during overloads or short circuits. This prevents damage to equipment and reduces fire hazards. However, even the best designs can fail if not maintained properly.

Understanding the working principle of switchgear is essential for safe operations. It involves complex mechanisms that can sometimes lead to misunderstandings. Operators may overlook maintenance schedules, leading to unexpected failures. A regular check-up on these devices can help in identifying potential issues. Awareness and education are vital in avoiding mistakes. Proper training can improve the overall efficiency and reliability of electrical systems.

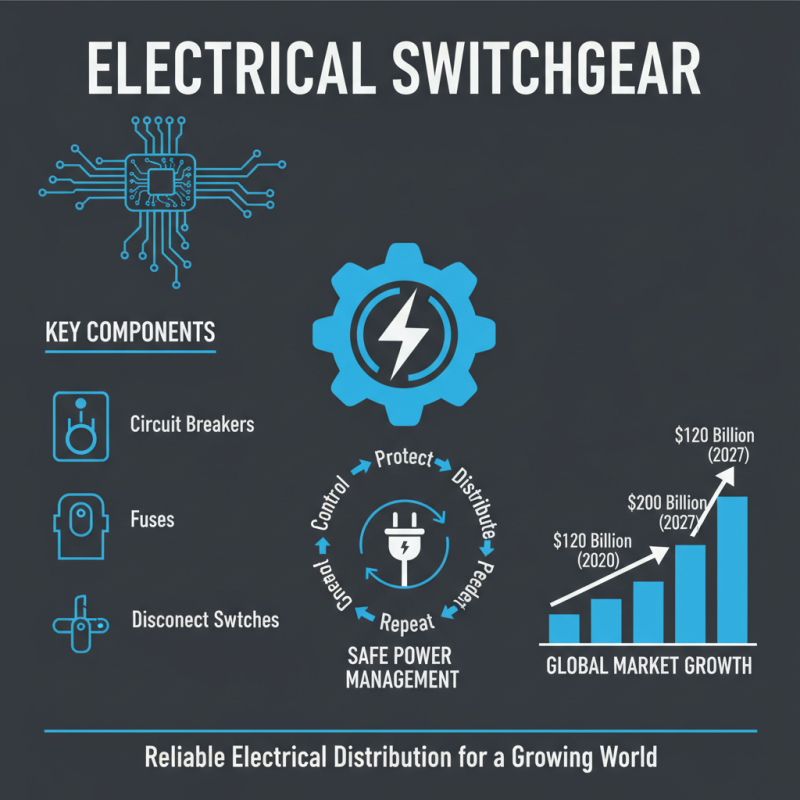

Components of Electrical Switchgear and Their Functions

Electrical switchgear is composed of various critical components, each serving a specific purpose in managing electrical power. Circuit breakers are key devices that protect electrical circuits. They interrupt the flow of current during faults. Often, they can be reset manually after tripping.

Disconnect switches also play an essential role. These switches isolate parts of the electrical system for maintenance. Having them in place increases safety for workers.

Transformers are another component, adjusting voltage levels. However, sizing these transformers correctly is a common challenge.

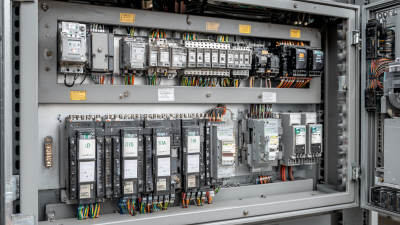

Busbars distribute electrical power throughout the switchgear. They are metal bars that connect different circuits. Proper insulation is essential to prevent short circuits.

Control panels are vital, providing monitoring and control functionalities. The design of these panels can sometimes be overwhelming for operators. Each component is crucial; however, ensuring they work together seamlessly requires regular assessment and improvement.

Types of Electrical Switchgear Used in Power Systems

Electrical switchgear plays a vital role in power systems. Various types of switchgear are utilized, each serving specific needs. The most common include air-insulated switchgear (AIS), gas-insulated switchgear (GIS), and hybrid switchgear.

AIS is often preferred for its lower initial cost. It also requires more space, which can be a limitation in urban areas.

Gas-insulated switchgear, on the other hand, can operate in smaller areas. According to a market report by Mordor Intelligence, GIS demand is expected to grow at a CAGR of 6.7% from 2021 to 2026. This growth is driven by the need for high reliability in crowded spaces. Hybrid switchgear combines elements of AIS and GIS, offering flexibility with a smaller footprint. However, its complex design can lead to higher maintenance needs.

Tip: Regular maintenance is crucial for switchgear longevity. Schedule inspections every six months to prevent unexpected failures. Also, consider the environment where the switchgear operates. Dust and humidity can affect performance.

Another detail to ponder: the choice of switchgear influences operational costs. AIS might seem cost-effective initially, but GIS can reduce long-term operational and maintenance expenses. Weigh these factors carefully in your decision-making process. Finding the right balance is key to efficiency.

How Electrical Switchgear Operates in Electrical Circuits

Electrical switchgear is vital in managing electrical circuits. It includes various devices like circuit breakers, fuses, and disconnect switches. These components work together to control the flow of electricity safely. In fact, the global switchgear market is expected to reach $200 billion by 2027, according to industry reports. This growth indicates the rising importance of reliable electrical distribution systems.

When electrical currents flow through circuits, switchgear acts as a protective barrier. For instance, if an overload occurs, the circuit breaker disconnects the faulty section. This quick action can prevent fires or equipment damage. Studies show that around 20% of electrical failures are due to inadequate protection measures. Thus, effective switchgear performance is critical for maintaining system reliability.

However, not all switchgear operates flawlessly. Aging infrastructure poses significant risks. Older switchgear may fail to respond like newer models. The IEEE estimates that over 30% of electrical outages stem from outdated equipment. Regular maintenance is essential but often overlooked. Adopting modern technologies can enhance operational efficiency and minimize risks.

Maintenance and Safety Considerations for Electrical Switchgear

Electrical switchgear plays a crucial role in managing electricity flow. Regular maintenance is vital for safe and efficient operation. Inspections should be frequent, focusing on the physical condition of components. Check for signs of wear or damage, such as rust, cracks, or improper closures. It's easy to overlook these small details, but they can lead to larger issues.

Safety considerations cannot be ignored. Always ensure proper personal protective equipment (PPE) is worn during maintenance. Voltage checks are necessary to avoid electric shocks. Isolation procedures should be strictly followed. Workers must be trained to handle emergencies. Ignoring safety can lead to accidents or equipment damage.

Keeping records of maintenance is essential. Documentation helps track issues over time. However, not all staff might be diligent in updating these records. This can create gaps in knowledge about the equipment's history. Regular training and reminders can help keep everyone on the same page. These steps reinforce a culture of safety and reliability in electrical switchgear operation.

Electrical Switchgear Performance Metrics

This bar chart illustrates the key performance metrics of electrical switchgear, including maintenance frequency, failure rate, operational efficiency, downtime, and safety incidents, highlighting areas of focus for maintenance and safety considerations.

Related Posts

-

2025 How to Choose the Right Electrical Switchgear for Your Needs

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Top 10 Motors and Controls: Best Technologies for Optimal Performance