10 Essential Tips for Choosing the Right Soft Start Motor Starter

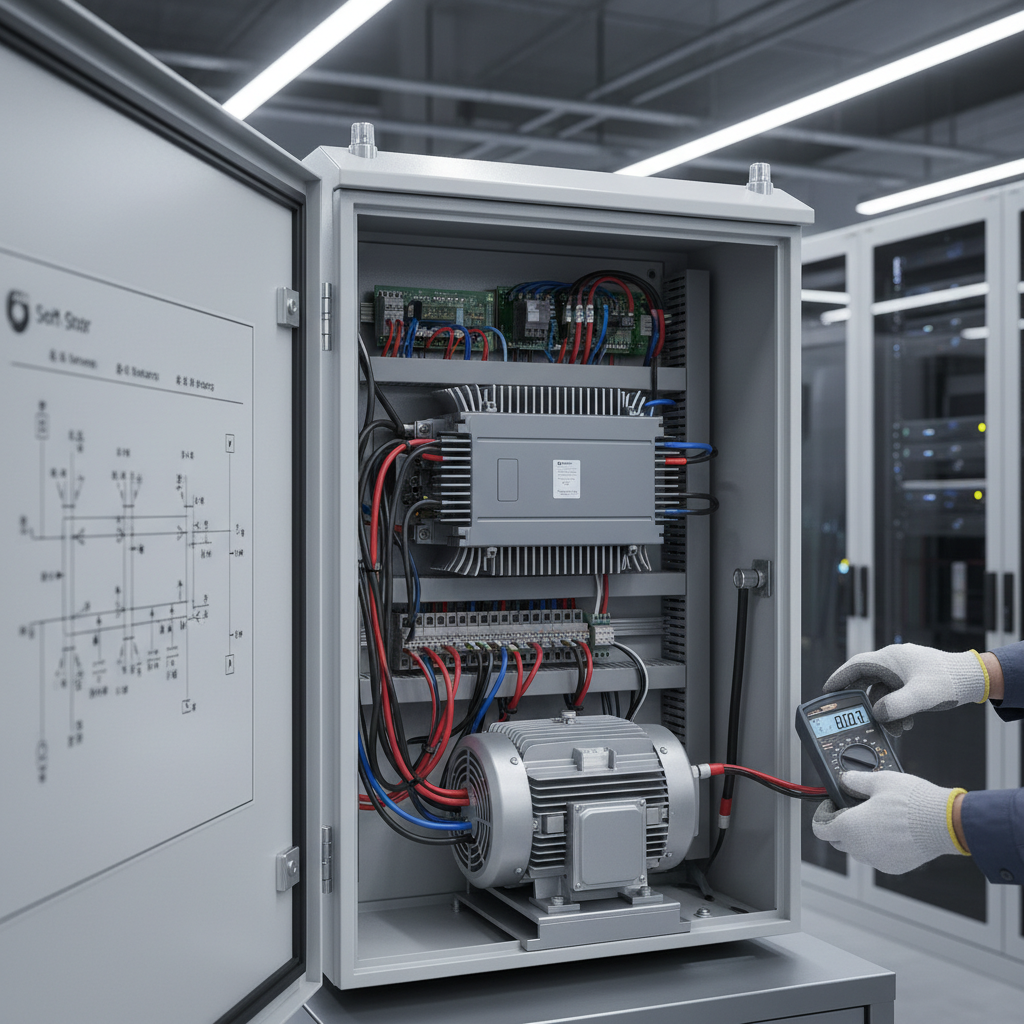

In the ever-evolving landscape of industrial automation, the selection of the appropriate soft start motor starter is pivotal for ensuring the efficient operation of motor-driven systems. According to a recent report by the International Electrotechnical Commission (IEC), improper motor management can lead to energy waste, increased maintenance costs, and reduced equipment lifespan, thus highlighting the critical need for diligent selection criteria. The soft start motor starter, designed to manage the inrush current during motor startup, not only enhances operational efficiency but also significantly mitigates wear and tear on mechanical components.

Industry expert Dr. Emily Henderson, a renowned electrical engineer and author in the field of motor control technology, emphasizes the necessity of understanding specific application requirements. She states, "Choosing the right soft start motor starter is not just about compatibility; it’s about future-proofing your operations for efficiency and reliability." This insight is particularly salient as industries rapidly adopt advanced technologies and seek to optimize performance. With projections from MarketsandMarkets indicating a compound annual growth rate (CAGR) of 6.5% in the soft starter market over the next few years, now is the ideal time for professionals to navigate the intricate criteria surrounding soft start motor starters, ensuring they make informed decisions tailored to their operational needs.

Key Considerations for Motor Size and Specifications

When selecting a soft start motor starter, understanding the motor size and specifications is crucial. The right starter not only enhances the motor's lifespan but also improves efficiency. According to a report by the National Electrical Manufacturers Association (NEMA), ensuring compatibility between the motor's horsepower and the starter's capacity can lead to a 10-15% reduction in energy consumption. This means considering the motor's service factor, voltage ratings, and phase configurations is essential for optimal performance.

One vital tip is to assess the starting torque required for your application. If the application demands high starting torque, ensure the soft starter can handle it without compromising performance. Additionally, not all applications require the same level of control; thus, evaluating whether a basic starter or a more advanced unit with programmable settings is necessary can further tailor your system for efficiency.

Another important consideration is the operational environment of your motor. A study published in the Journal of Electrical Engineering highlighted that approximately 30% of motor failures can be attributed to environmental factors, such as temperature and humidity. Therefore, selecting a soft starter with appropriate environmental ratings can mitigate risks and enhance reliability. Carefully weighing these factors will lead to informed choices that align with operational needs and durability objectives.

Understanding Soft Start Benefits for Your Application

When selecting the right soft start motor starter for your application, understanding the benefits it provides is crucial. Soft starters are designed to reduce the mechanical stress on your motors during startup, which can significantly extend their lifespan. According to a report by the National Electrical Manufacturers Association (NEMA), implementing a soft start can reduce motor startup current by up to 60%, minimizing the risk of damage and enhancing operational efficiency.

Moreover, soft starters contribute to energy savings, an increasingly important factor in today's industrial settings. A study by the U.S. Department of Energy indicates that using soft starters can decrease energy consumption during motor starting by as much as 30%. This not only leads to cost savings on electricity bills but also positively impacts the overall sustainability of industrial operations. The ability to customize the ramp-up time can optimize the startup process for various applications, ensuring a smooth transition and reducing potential downtime.

Evaluating Control Features and Customization Options

When selecting a soft start motor starter, evaluating its control features and customization options is crucial. Advanced control features can significantly enhance energy efficiency and performance. According to a report by the International Energy Agency, soft starters can improve efficiency by up to 30% in industrial applications, resulting in substantial energy savings and reduced operational costs. Choosing a starter with programmable settings allows you to fine-tune the ramp-up and ramp-down times, minimizing mechanical stress on equipment, which can prolong the lifespan of motors and reduce maintenance costs.

Tip 1: Look for a soft starter that offers adaptive control algorithms, which adjust the starting and stopping characteristics based on load conditions. This ensures optimal performance across various applications.

Customization options are equally important. A soft start motor starter that supports integration with existing control systems and can be tailored to specific operational needs greatly enhances flexibility. According to a report from Markets and Markets, the soft starter market is expected to grow by 5.8% annually, indicating a rising demand for customizable solutions that cater to diverse industrial applications.

Tip 2: Consider a starter with remote monitoring capabilities. This allows users to access real-time data on performance metrics, helping to make informed decisions regarding maintenance and operational efficiency.

In summary, prioritizing control features and customization can lead to improved energy savings and operational efficiency, ultimately providing better value for your investment.

10 Essential Tips for Choosing the Right Soft Start Motor Starter

This chart illustrates the importance of various control features and customization options when selecting a soft start motor starter. Each feature's significance is rated on a scale from 1 to 10.

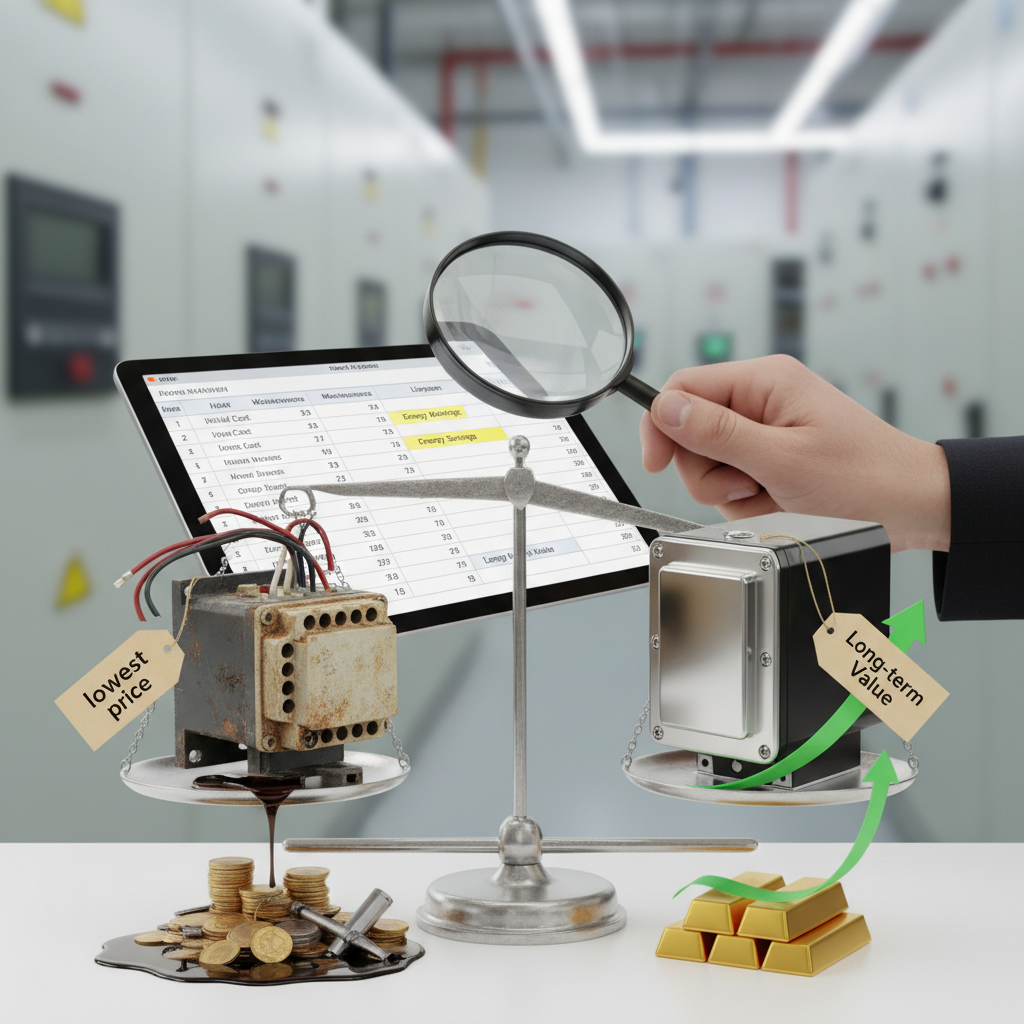

Assessing Budget and Long-Term Cost Effectiveness

When selecting a soft start motor starter, assessing your budget alongside the long-term cost-effectiveness is crucial for making a wise investment. Initially, while it might seem beneficial to opt for the cheapest option available, remember that the lowest price can often lead to higher maintenance costs down the line. Therefore, it's important to evaluate the overall value rather than just the initial expenditure.

One of the essential tips is to consider the reliability of the manufacturer. Investing in a product from a reputable brand might come with a higher upfront cost, but it typically results in reduced maintenance needs and longer service life. Additionally, analyze the energy savings that a soft starter can provide. Choosing a model that minimizes energy consumption not only lowers operating costs but also contributes positively to your long-term budget strategy.

Another tip to keep in mind is the scalability of the motor starter. As your operation grows, your equipment needs may change. Ensure that the soft start motor starter you choose can accommodate future expansions without incurring significant additional costs. This foresight can help protect your investment and enhance cost efficiency over time.

Ensuring Compatibility with Existing Systems and Equipment

When selecting a soft start motor starter, ensuring compatibility with existing systems and equipment is paramount. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that approximately 30% of motor failures are attributed to poor integration with control systems. Therefore, before finalizing a choice, assess the voltage ratings and control logic of your machinery to guarantee seamless connectivity.

Tip 1: Evaluate the Load Type

Different applications may require varying configurations, such as star-delta or voltage ramp start. Analyzing the load type—whether it be constant torque or variable torque—helps in selecting a soft starter that can accommodate these parameters effectively, resulting in enhanced operational efficiency.

Tip 2: Check Communication Protocols

Modern soft start starters often include integrated communication options like Modbus or Profibus. Ensure that the selected starter can communicate with your existing automation systems. Reports indicate that over 40% of processing companies identified communication incompatibility as a significant barrier to operational efficiency.

Ensuring compatibility not only prolongs the lifespan of your equipment but also assists in maximizing performance and minimizing downtime.

10 Essential Tips for Choosing the Right Soft Start Motor Starter - Ensuring Compatibility with Existing Systems and Equipment

| Tip | Description | Considerations | Benefits |

|---|---|---|---|

| 1. Determine Motor Size | Assess the motor's power requirements to select a compatible soft starter. | Check the motor's horsepower and voltage ratings. | Avoid damaging the motor and ensure efficient operation. |

| 2. Check Compatibility | Ensure the soft starter is compatible with existing equipment. | Review specifications and existing system requirements. | Prevent system failures and ensure seamless integration. |

| 3. Evaluate Control Features | Look for advanced control features such as digital settings. | Consider the complexity of the application and user interface. | Enhanced control over motor start-up and braking. |

| 4. Assess Overload Protection | Ensure that the soft starter offers adequate overload protection options. | Understand the motor's load characteristics. | Prevents motor damage from excessive loads. |

| 5. Look for Energy Efficiency | Choose models that optimize energy consumption during operation. | Analyze energy costs and potential savings. | Lower operational costs and environmental impact. |

| 6. Consider Size and Design | Select a soft starter with an appropriate physical size for your space restraints. | Evaluate installation space and panel layout. | Simplifies installation and maintenance in confined areas. |

| 7. Review Manufacturer Support | Choose a manufacturer known for offering support and service. | Research available customer service options and reviews. | Ensures resolution of issues and minimizes downtime. |

| 8. Ensure Compliance with Standards | Verify that the soft starter meets necessary industry safety standards. | Check relevant standards for your region or industry. | Promotes safety and reduces liability risks. |

| 9. Analyze Installation Requirements | Understand the requirements for installing the soft starter. | Consider electrical and mechanical installation guidelines. | Facilitates a smoother installation process. |

| 10. Compare Costs | Study various pricing options and what they offer. | Balance cost against features and long-term benefits. | Ensures value for money spent on motor starters. |

Related Posts

-

2025 Top 5 Motor Soft Starter Options for Efficient Energy Management

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters

-

Understanding the Future of Motors and Controls in Sustainable Technology

-

How to Choose the Right Circuit Breaker for Your Home Electrical System

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders