Understanding the Role of Industrial Electric Motors in Modern Automation Systems

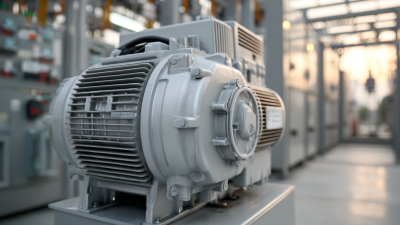

In the realm of modern automation systems, industrial electric motors play a pivotal role in enhancing efficiency and productivity across various sectors. According to a report by MarketsandMarkets, the global industrial electric motor market is expected to reach $159.5 billion by 2025, driven by the increasing adoption of automation technologies and the need for energy-efficient solutions. These motors serve as the backbone of numerous applications, from manufacturing assembly lines to robotics and process control, making them indispensable in today's industrial landscape. As businesses strive for greater operational excellence and sustainability, understanding the different types and functionalities of industrial electric motors becomes crucial. This guide will delve into the various types of industrial electric motors, their applications, and best practices for optimizing their performance within automation systems.

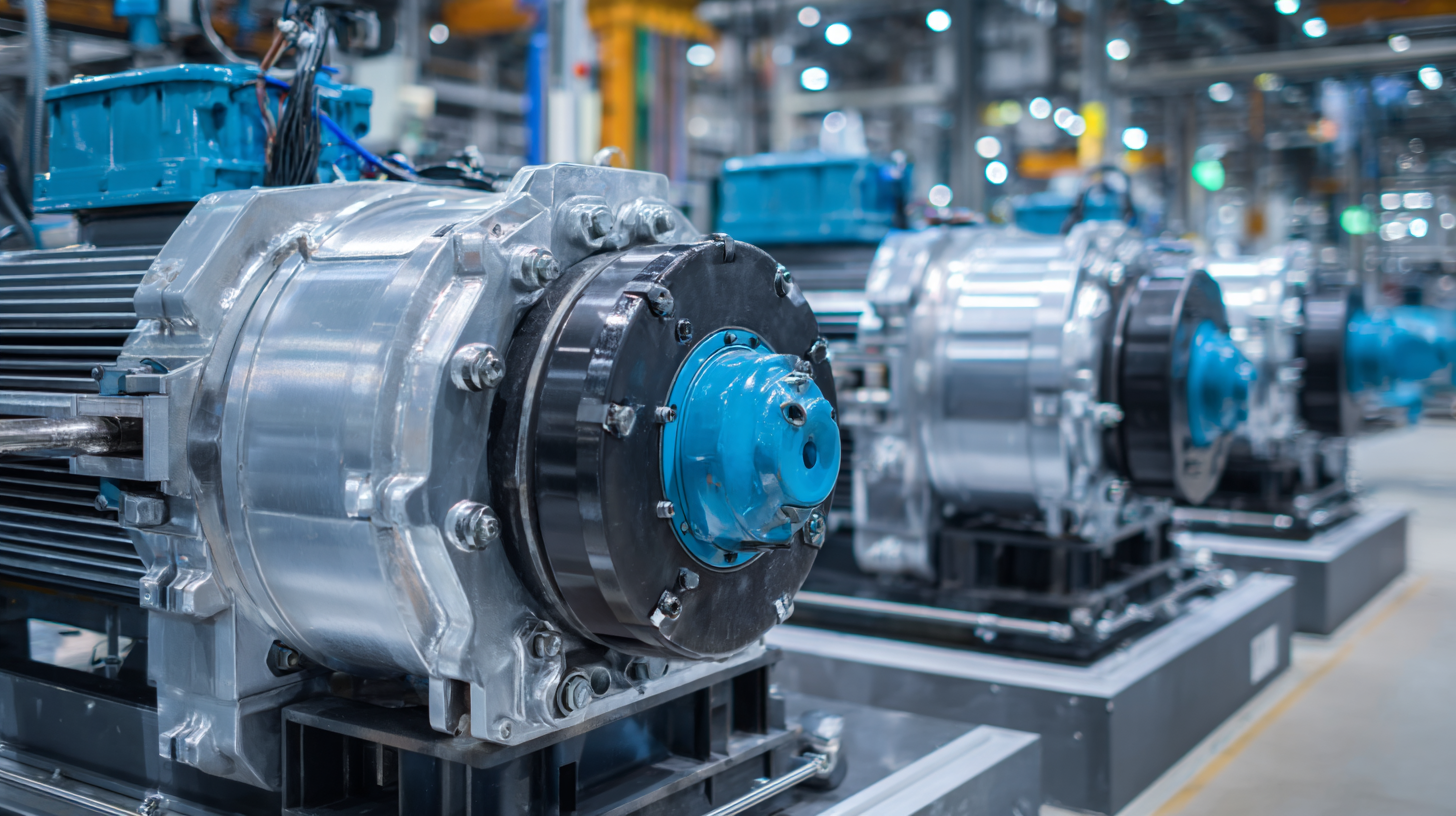

Types of Industrial Electric Motors Used in Automation Systems

In the realm of automation systems, industrial electric motors play a pivotal role, with various types tailored to specific applications. The global low voltage electric motor market is projected to expand significantly, anticipated to grow from $67.11 billion in 2025 to $108.09 billion by 2032, showcasing a compound annual growth rate (CAGR) of 7.05%. This growth reflects the increasing reliance on electric motors in advancing automation technologies, seamlessly integrating with Internet of Things (IoT) and artificial intelligence (AI) to optimize operational efficiency.

Among the types of motors prevalent in industrial automation, AC motors and DC motors are the most common. AC motors are particularly favored for their robustness and efficiency in driving heavy loads, making them ideal for manufacturing and processing industries. On the other hand, DC motors are valued for their precision and controllability, often employed in applications requiring variable speed and torque. With the industrial motor market expected to reach USD 1.04 billion by 2033, the demand for these diverse motor types underscores their essential contribution to modern industrial automation systems.

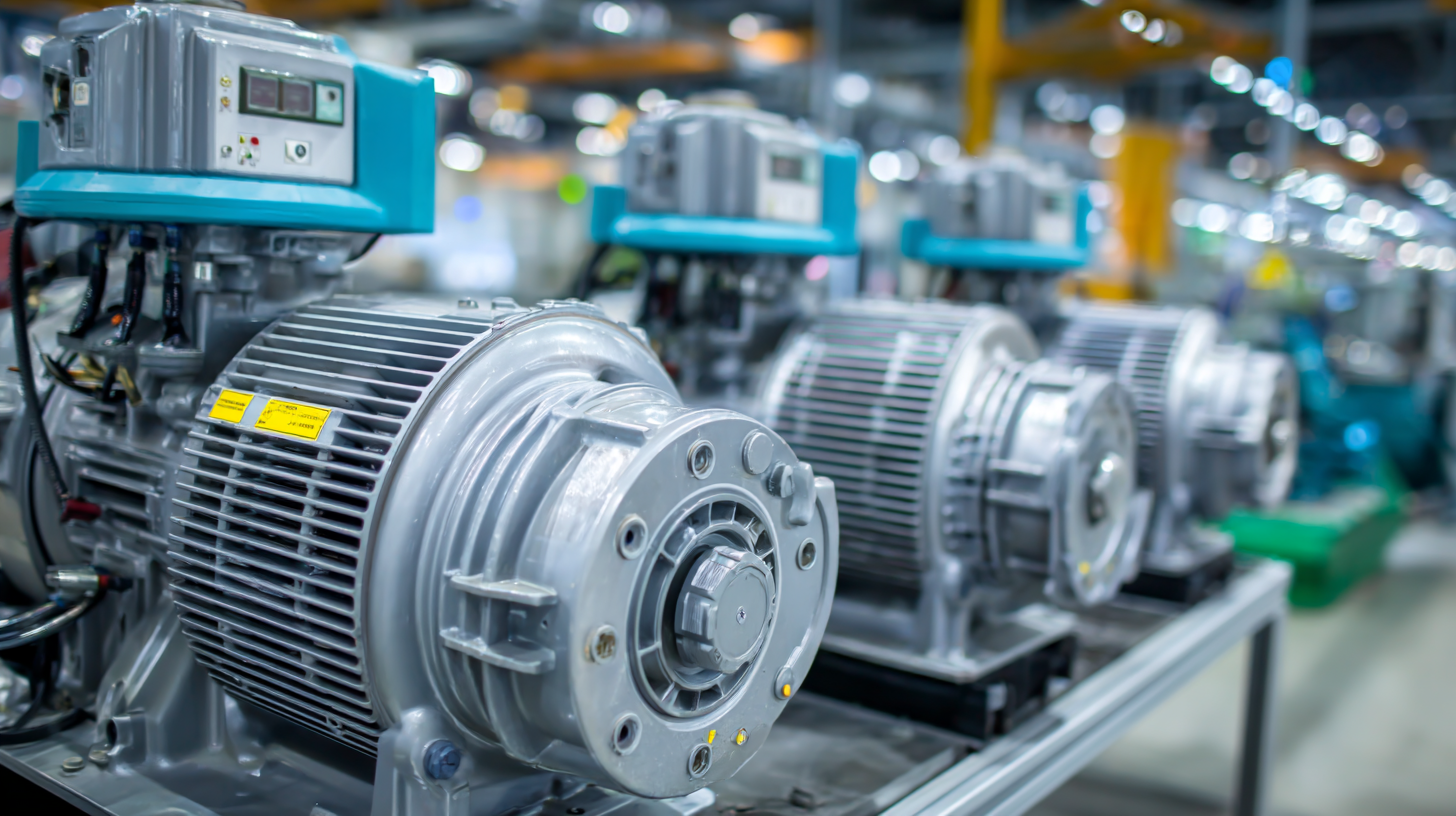

Key Features and Benefits of Electric Motors in Automation

Electric motors are pivotal components in modern automation systems, bringing numerous key features and benefits that enhance operational efficiency. One of the standout features is their ability to provide precise control over speed and torque. This level of control is essential in manufacturing processes where the accuracy of movement directly impacts product quality. Moreover, advancements in motor technology, such as brushless and servo motors, allow for smoother operations with reduced mechanical wear, resulting in prolonged equipment lifespan.

In addition to precision, electric motors contribute significantly to energy efficiency. Compared to their hydraulic or pneumatic counterparts, electric motors consume less power, leading to lower operational costs and a reduced carbon footprint. Their integration into automated systems allows for seamless coordination with other machinery, facilitating a quicker response to changing production demands. Furthermore, the reduced maintenance requirements associated with electric motors lower downtime, ensuring that production lines remain operational. Overall, the role of electric motors in automation represents a blend of reliability, efficiency, and innovation, driving industries towards smarter and more sustainable practices.

Understanding the Role of Industrial Electric Motors in Modern Automation Systems

| Feature | Description | Benefits |

|---|---|---|

| Efficiency | Electric motors convert electrical energy into mechanical energy with high efficiency. | Reduces energy costs and enhances overall system performance. |

| Compact Size | Electric motors can be designed to be smaller than traditional motor types while maintaining power output. | Saves space in automation systems and allows for more flexible designs. |

| Low Maintenance | Electric motors typically require less maintenance than mechanical counterparts. | Minimizes downtime and reduces maintenance costs. |

| Control Precision | Advanced control systems can modulate the speed and torque of electric motors easily. | Enhances process control and improves product quality. |

| Environmental Impact | Electric motors produce no emissions during operation. | Helps organizations meet sustainability goals and regulatory requirements. |

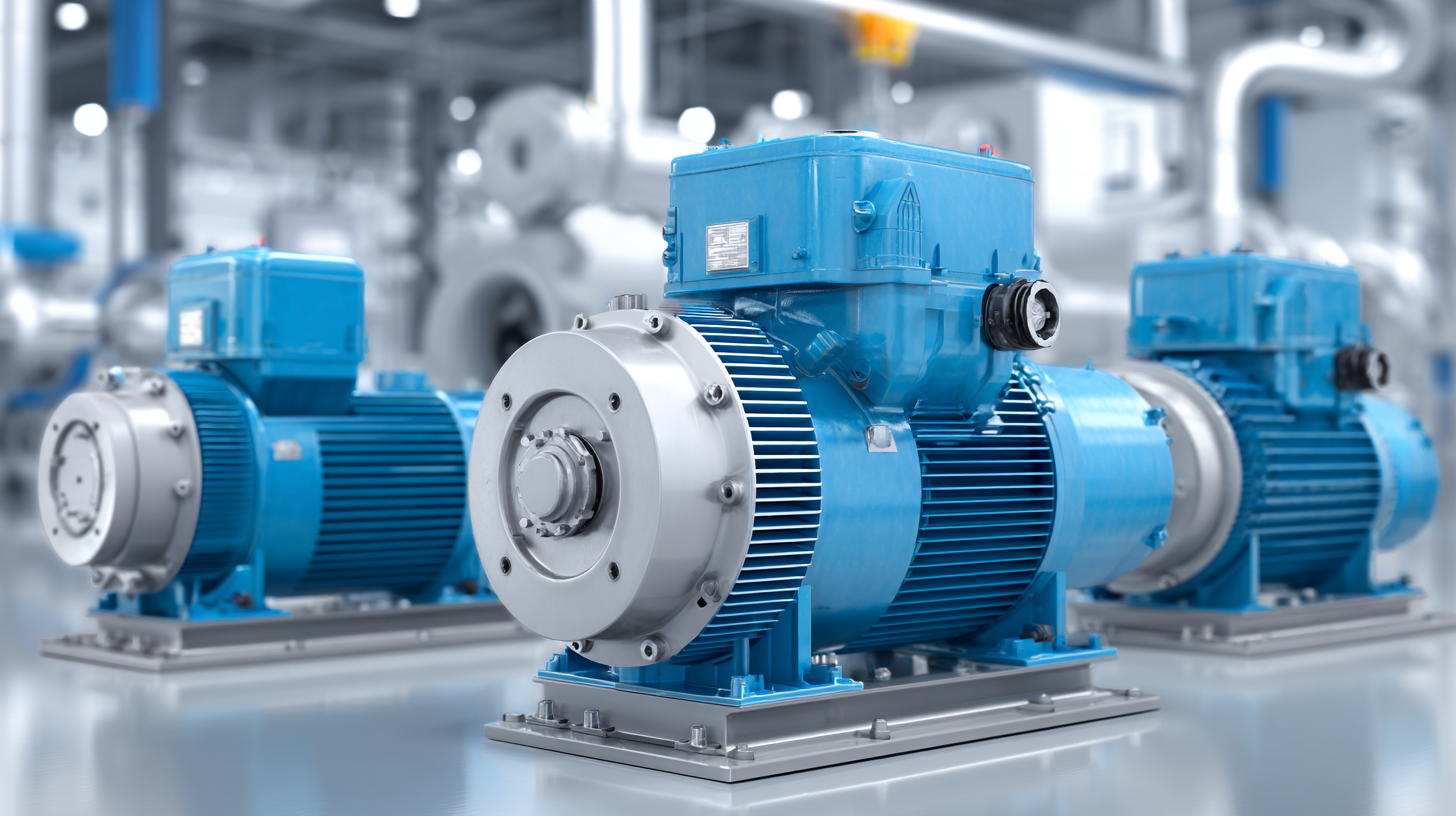

Selecting the Right Electric Motor for Your Automation Needs

Selecting the right electric motor for your automation needs is crucial for optimizing productivity and ensuring efficient operations. According to a report by MarketsandMarkets, the global industrial electric motor market is projected to grow from USD 98.01 billion in 2020 to USD 140.83 billion by 2026, indicating a robust demand fueled by advancements in automation technologies. Selecting the appropriate motor not only impacts energy efficiency but also influences maintenance costs and overall system reliability.

When evaluating options, consider the motor's type—AC or DC—based on your application's power requirements and operational characteristics. For instance, AC motors are often favored for their durability and cost-effectiveness in fixed-speed applications, while DC motors provide higher torque and variable speed control, ideal for dynamic processes.

Tips: Always assess the torque and speed requirements specific to your process; mismatches can lead to inefficiencies and premature motor failure. Additionally, look into energy-efficient models that adhere to the latest IE (International Efficiency) standards, as they can substantially reduce operational costs over time while meeting environmental compliance.

Integrating Electric Motors into Automated Systems: Best Practices

Integrating electric motors into automated systems requires a thorough understanding of the specific application and its requirements. The selection of the right motor type—AC, DC, or stepper—depends on factors such as load characteristics, speed, and torque requirements. It’s essential to align the motor specifications with the automation system’s goals to ensure seamless operation and efficiency. Proper sizing and selection help prevent mechanical failures and optimize performance, extending the lifespan of both the motor and the entire system.

Additionally, establishing effective communication between the electric motors and the control systems plays a crucial role in automation. Utilizing advanced feedback systems such as encoders and sensors can enhance the precision and responsiveness of the motors in various applications. Moreover, adhering to best practices like implementing proper wiring, ensuring adequate cooling, and conducting regular maintenance will significantly improve reliability and performance. By focusing on both the technical specifications and practical integration strategies, businesses can maximize the potential of industrial electric motors within their automated environments.

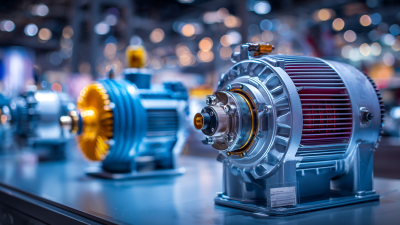

Future Trends in Industrial Electric Motors for Automation Applications

The future of industrial electric motors in automation applications is poised for significant transformation, driven by advancements in technology and increasing demands for efficiency. As industries strive to enhance productivity and reduce energy consumption, smart electric motors equipped with IoT capabilities are becoming increasingly prevalent. These motors enable real-time monitoring and predictive maintenance, allowing companies to address potential issues before they result in costly downtime.

Another key trend is the integration of artificial intelligence and machine learning into motor control systems. This evolution allows motors to operate more intelligently, adapting their performance based on changing workload conditions. Moreover, the rise of sustainable manufacturing practices is leading to a greater emphasis on energy-efficient motor designs, such as those utilizing permanent magnet technology. These innovations not only help reduce operational costs but also support corporate sustainability goals, making industrial electric motors a critical component of future automation systems.

Future Trends in Industrial Electric Motors for Automation Applications

Related Posts

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

Exploring Electric Motors Innovations at the 2025 China Import and Export Fair

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Exploring the Future: Motor Starters at the 138th Canton Fair 2025 and Industry Trends

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

How to Choose the Right Circuit Breaker for Your Home Electrical System