What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

In recent years, the advancement of electric motors has been pivotal in reshaping industry efficiency and sustainability. According to a report by the International Energy Agency (IEA), electric motors account for approximately 45% of the global electricity consumption in industrial applications, underlining their significance in energy use. Moreover, a study referenced by McKinsey highlights that optimizing electric motor systems can yield energy savings of up to 30%. Innovations such as advanced materials and smart technologies are propelling the development of more efficient electric motors, enabling industries to reduce their carbon footprint and operational costs. As companies strive for greater sustainability, the ongoing improvements in electric motors represent a crucial step towards greener industrial practices, promising not only enhanced efficiency but also a profound impact on the global transition to renewable energy sources.

Recent Advances in Electric Motor Design Enhancing Energy Efficiency in Industrial Applications

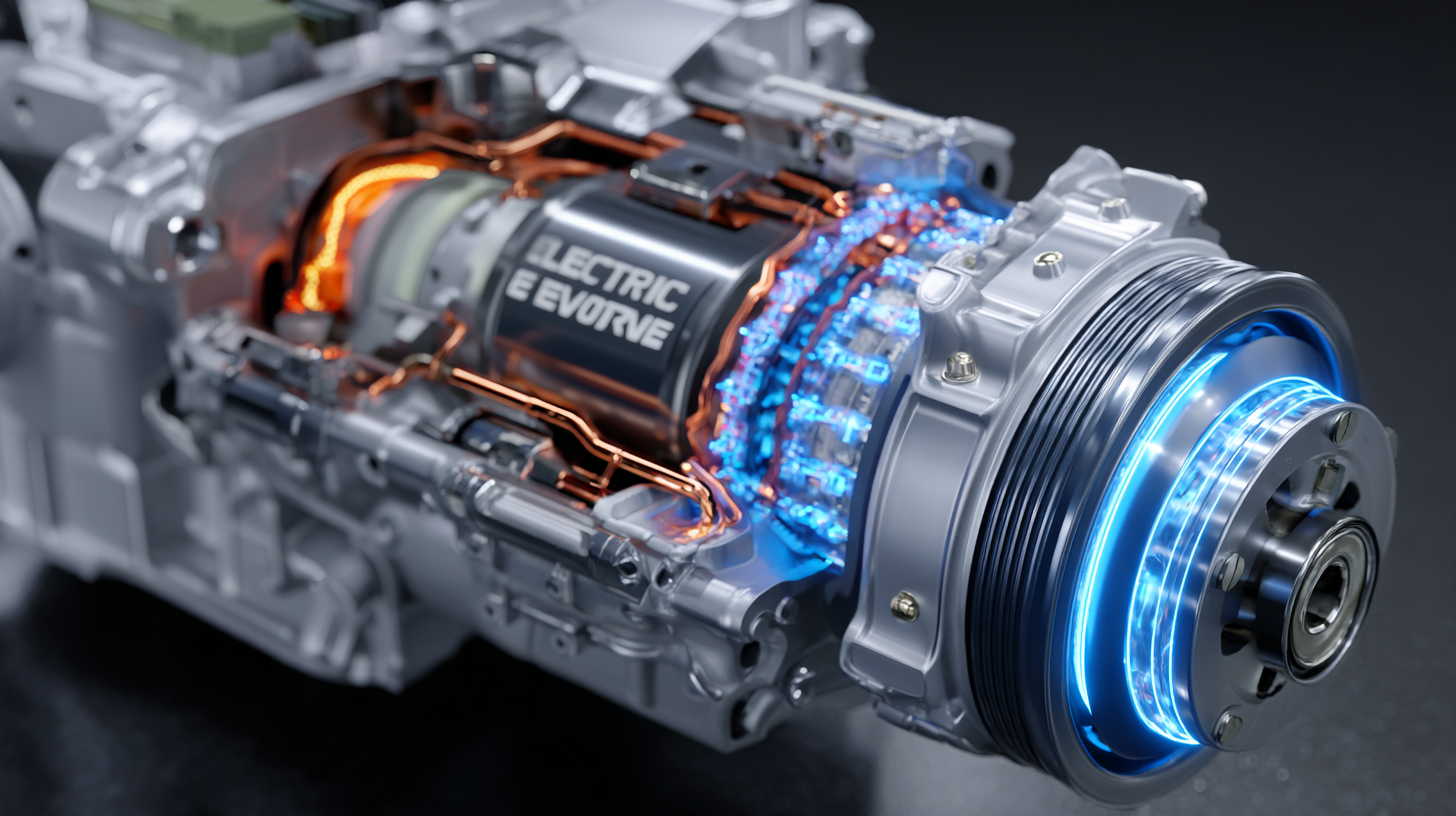

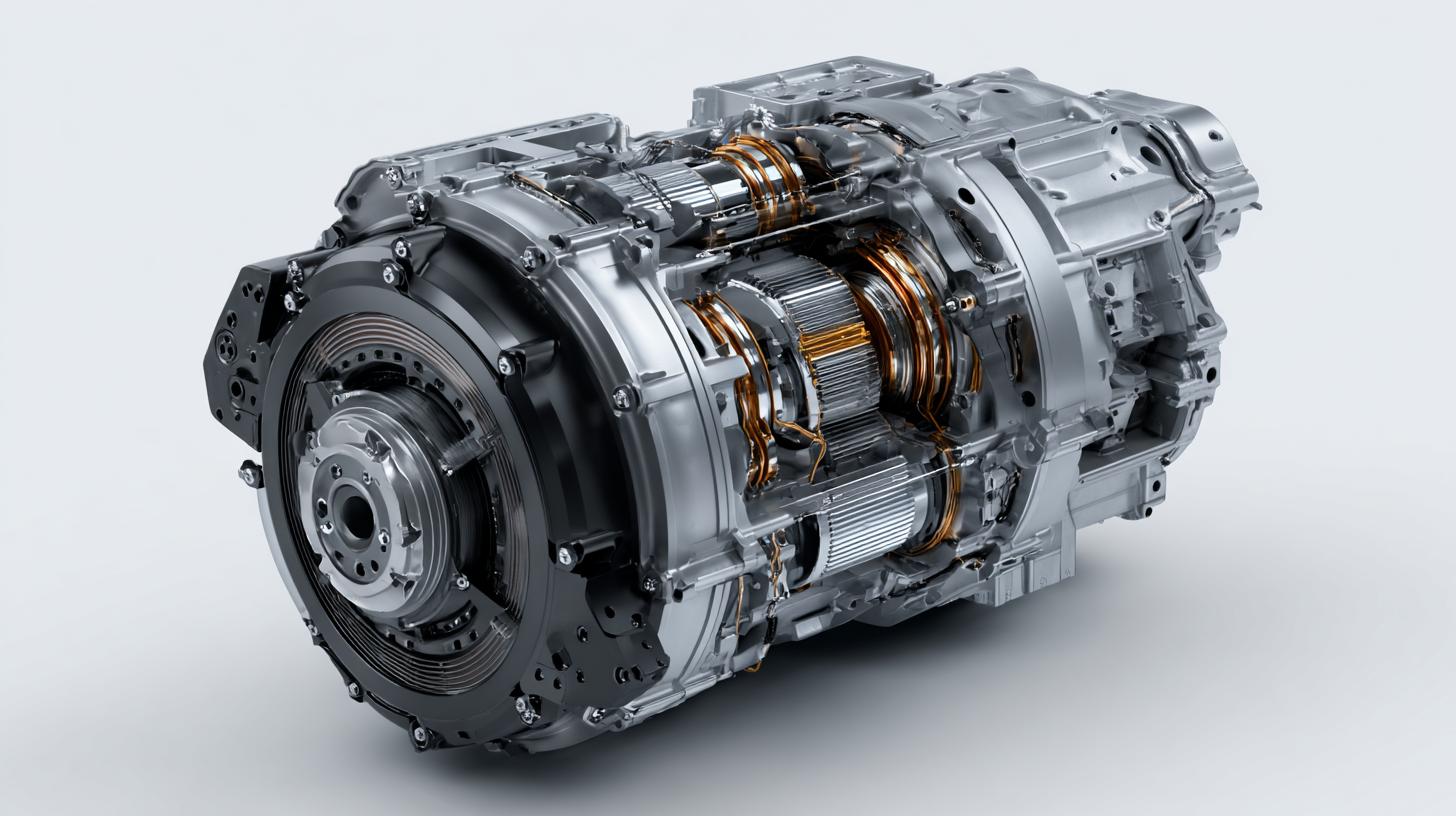

Recent advances in electric motor design have significantly enhanced energy efficiency in various industrial applications, responding to the growing demand from the industrial sector for more sustainable solutions. As industries strive for operational excellence, the shift towards energy-efficient motors has gained momentum. These innovations not only optimize performance but also reduce overall energy consumption, contributing to a more sustainable industrial environment. Improved designs incorporate features such as advanced materials and innovative cooling techniques, which collectively enhance the longevity and effectiveness of electric motors.

In parallel, the evolution of electric vehicle technologies has further propelled the energy-efficient motor market. Research focusing on electric vehicle traction motors emphasizes maximizing mechanical efficiency, which is crucial for improving overall vehicle performance and battery life. Strategies for better thermal management are central to these developments, ensuring that motors operate at optimal temperatures, thus enhancing reliability and efficiency. As both industries continue to push the boundaries of what electric motors can achieve, the integration of these advanced systems promises not only to drive efficiency but also to pave the way towards a more sustainable future.

The Role of Smart Technology in Optimizing Electric Motor Performance and Lifespan

The integration of smart technology in electric motors is revolutionizing their performance and longevity, marking a significant stride towards industry efficiency and sustainability. By utilizing advanced sensors and algorithms, these smart systems optimize energy consumption and reduce wear and tear, ultimately extending the lifespan of electric motors. This is particularly crucial in applications like electric vehicles, where enhanced thermal management technologies can mitigate energy losses due to heat generation, ensuring that more power is effectively used for propulsion.

**Tip 1:** When selecting electric motors or related technologies, prioritize those that incorporate smart features such as real-time monitoring and predictive maintenance. This can significantly enhance overall system efficiency and reduce downtime.

Moreover, the growing demand for electric motors in various sectors underscores the importance of continuous innovation. As the market is projected to reach $23.87 billion in 2023, the emphasis on smart technology not only improves operational efficiency but also aligns with sustainability goals. Innovations in electric motor design, coupled with smart technology, will play a pivotal role in meeting the increasing energy efficiency standards and environmental regulations.

**Tip 2:** Keep an eye on emerging technologies in electric motor design that focus on reducing environmental impact. Innovations like regenerative braking systems and energy-efficient driving modes can contribute greatly to sustainability while optimizing motor performance.

Latest Innovations in Electric Motors for Industry Efficiency and Sustainability

This chart illustrates the improvements in electric motor efficiency and lifespan driven by smart technology innovations over recent years. The data represents the percentage increase in efficiency and lifespan attributed to various technological advancements.

Impact of Electric Motor Innovations on Reducing Carbon Emissions in Manufacturing

The manufacturing sector is undergoing a transformation through the latest innovations in electric motors, which are significantly impacting carbon emissions. Advances in motor design, such as increased efficiency and reduced size, enable industries to adopt electric systems that consume less energy while delivering higher performance. This shift not only enhances productivity but also plays a crucial role in decreasing the overall carbon footprint associated with manufacturing processes.

Moreover, the use of smarter electric motors equipped with IoT capabilities allows for real-time monitoring and optimization of energy consumption. By integrating predictive maintenance and automation, these motors can function at peak efficiency, further minimizing environmental impact. As manufacturers increasingly prioritize sustainability, the innovations in electric motors are not just beneficial for operational efficiency; they are essential for achieving corporate sustainability goals and complying with stricter environmental regulations. The result is a powerful synergy between technological advancement and ecological responsibility, paving the way for a greener industrial future.

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

| Innovation | Description | Impact on Efficiency (%) | Reduction in Carbon Emissions (kg CO2/year) |

|---|---|---|---|

| Permanent Magnet Motors | Utilize high-performance magnets to increase efficiency. | 15 - 20 | 2000 |

| High-Efficiency Induction Motors | Designed for minimal losses and greater output. | 10 - 15 | 1500 |

| Integrated Motor Drives | Combined motor and controller in one unit for better performance. | 12 - 18 | 1800 |

| Electromechanical Actuators | Precise motion control applications for enhanced operations. | 20 - 25 | 2200 |

| Switched Reluctance Motors | Robust design with high efficiency for variable speed applications. | 15 - 22 | 2100 |

Comparative Analysis of Electric Motor Types: Energy Consumption and Sustainability Metrics

Electric motors are at the forefront of advancing energy efficiency and sustainability across various industries. Different types of electric motors exhibit varying energy consumption levels and sustainability metrics, making it essential to evaluate their performance against industry needs. For instance, brushless DC motors are often more efficient than their brushed counterparts, resulting in lower energy consumption and longer service life, while induction motors provide robust solutions for high-power applications. Understanding these differences helps businesses make informed decisions that align with their sustainability goals.

In line with these innovations, companies like the one in Jiangxi Province have adopted advanced management techniques to significantly reduce energy consumption. By optimizing processes and integrating high-efficiency electric motors, they have exceeded their production targets while minimizing their environmental footprint. This shift towards greener practices not only enhances operational efficiency but also supports broader initiatives for sustainable industrial transformation. As industries continue to innovate in electric motor technologies, the potential for improved sustainability becomes increasingly viable, paving the way for further advancements in energy-conserving practices.

Future Trends in Electric Motor Technology: Predictions for Industry Transformation by 2030

The electric motor industry is on the cusp of a transformative era as we look towards 2030. With rapid advancements in technology, several trends are emerging that promise to enhance efficiency and sustainability across multiple sectors. One of the key developments is the integration of AI and IoT in electric motor systems, allowing for real-time monitoring and predictive maintenance. This minimizes downtime and optimizes energy consumption, leading to significant cost savings and reduced carbon footprints for manufacturing plants.

Another notable trend is the shift towards more sustainable materials and innovative manufacturing processes. As the demand for greener solutions intensifies, manufacturers are increasingly adopting recyclable materials and environmentally friendly production methods. Additionally, advancements in motor design, such as the use of high-temperature superconductors, are likely to improve the performance and reduce the size of electric motors, making them more suitable for a wider range of applications. By 2030, the combination of these innovative technologies and sustainable practices will revolutionize the electric motor industry, making it a cornerstone of a more efficient and eco-friendly future.

Related Posts

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

Comprehensive Guide to Optimizing Your Motor and Control Solutions for Enhanced Efficiency

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications