Top Motor and Control Solutions for Enhanced Efficiency and Performance

As industries strive for increased efficiency and performance, the role of motor and control solutions has never been more critical. According to a recent report by the International Energy Agency, electric motors account for nearly 45% of global electricity consumption in industrial applications. This staggering figure highlights the necessity for advanced motor and control solutions that not only optimize energy use but also enhance operational performance across various sectors.

Renowned industry expert Dr. Emily Parker, a leading authority on automation technology, emphasizes the importance of innovation in this field, stating, “The future of industrial productivity lies in how effectively we harness motor and control solutions to integrate smart technologies and improve energy efficiency.” As manufacturers adopt more sophisticated systems, the demand for high-performance motors and intelligent control solutions will continue to grow, driving advancements that can lead to significant cost reductions and sustainability benefits.

In this context, the exploration of cutting-edge motor and control solutions is essential for businesses aiming to remain competitive. By leveraging the latest technologies, organizations can not only enhance productivity but also contribute to sustainable practices that are increasingly vital in today's eco-conscious environment.

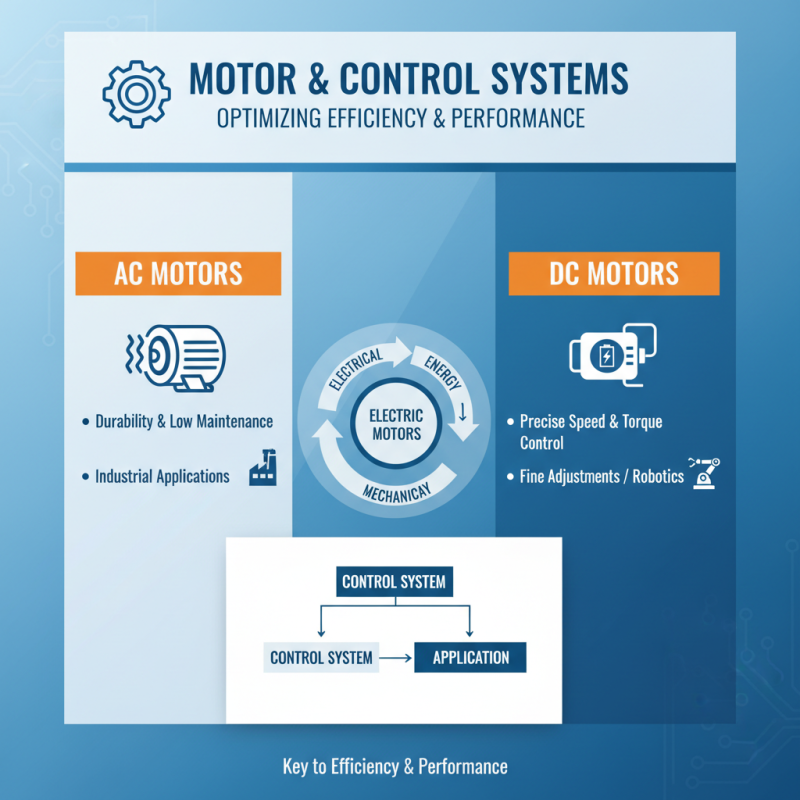

Understanding the Basics of Motor and Control Systems

Understanding motor and control systems is fundamental for optimizing efficiency and performance in various applications. At the core of these systems are electric motors, which convert electrical energy into mechanical energy. Different types of motors, such as AC and DC motors, each serve specific functions depending on the requirements of the application. AC motors are often preferred for their durability and low maintenance, making them suitable for industrial settings, whereas DC motors offer precise control over speed and torque, making them ideal for applications where fine adjustments are necessary.

Control systems play a pivotal role in how motors operate, providing the necessary commands to maintain desired performance levels. These systems can be as simple as basic on/off switches or more complex, involving programmable logic controllers (PLCs) and variable frequency drives (VFDs). By regulating the power supply to the motor, control systems optimize performance and energy consumption. They enable features such as speed regulation, torque control, and soft start capabilities, which can significantly enhance the overall efficiency of a motor-driven system. Understanding the interplay between motors and their control systems is essential for engineers and technicians looking to improve performance and reduce energy wastage in their operations.

Key Factors Influencing Motor Efficiency and Performance

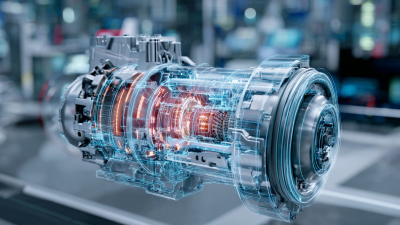

The efficiency and performance of motors are influenced by several key factors that play a significant role in their operation. One of the primary aspects is the design of the motor itself, including the choice of materials and construction techniques.

High-quality materials contribute to reduced energy loss, while advanced design strategies can enhance the magnetic and thermal characteristics of the motor, leading to improved performance. Additionally, optimization of the rotor and stator configurations can lead to a better power-to-weight ratio and increased torque output, which are critical for achieving higher efficiency.

Another crucial influence on motor performance is the type of control system employed. Advanced control strategies, such as vector control or direct torque control, allow for precise regulation of motor speed and torque, ensuring that the motor operates at its optimal efficiency under varying loads. Additionally, the integration of smart technologies, which utilize sensors and feedback loops, enables real-time adjustments that can further enhance performance and energy savings. By focusing on these factors—motor design and control systems—manufacturers and engineers can significantly elevate the operational efficiency of motors, thereby meeting the growing demand for energy-efficient solutions in various applications.

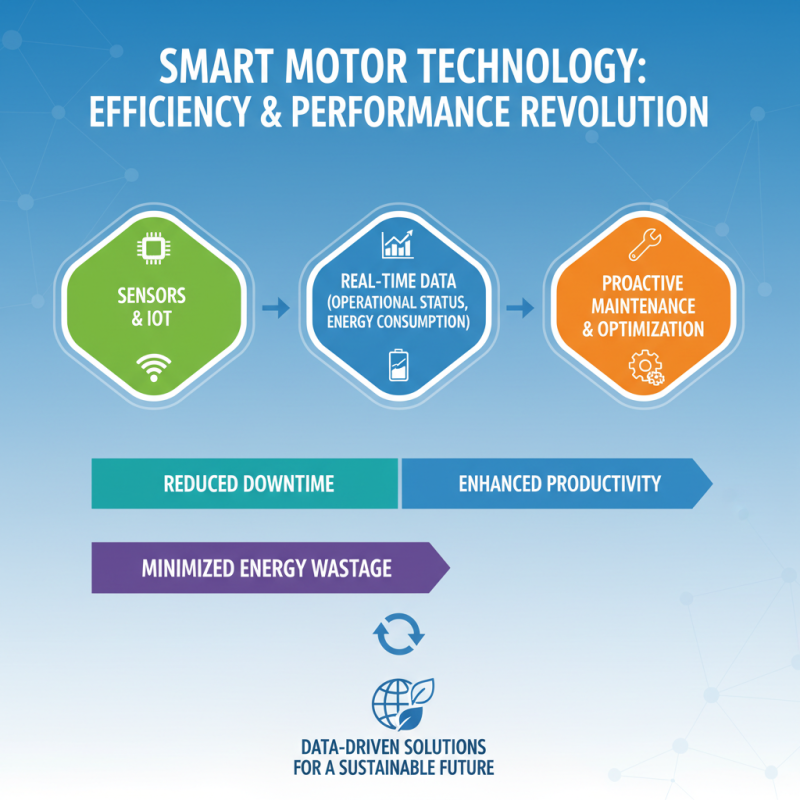

Latest Innovations in Motor Technologies

Recent advancements in motor technologies have paved the way for significant improvements in efficiency and performance across various industries. One of the most notable innovations is the development of smart motors, equipped with sensors and IoT capabilities. These motors can communicate real-time data regarding their operational status and energy consumption, allowing for proactive maintenance and optimization. This shift towards data-driven solutions empowers manufacturers to reduce downtime and enhance productivity while minimizing energy wastage.

Another breakthrough in motor technology is the rise of high-efficiency designs, which incorporate advanced materials and innovative cooling techniques. By optimizing the magnetic properties and thermal management of motors, engineers are achieving higher power densities and reduced energy losses. These improvements not only lead to lower operating costs but also contribute to sustainability goals by decreasing overall energy consumption. The integration of these cutting-edge technologies ensures that modern motors can meet the demands of today's dynamic industrial landscape, providing greater reliability and performance.

Advanced Control Solutions for Optimal Motor Operation

In today's fast-paced industrial environment, optimizing motor operation through advanced control solutions plays a critical role in enhancing both efficiency and performance. With the integration of sophisticated algorithms and real-time data analysis, modern control systems can significantly improve motor responsiveness and adaptability. These solutions not only ensure precise control of motor speed and torque but also contribute to energy savings and reduced wear and tear on mechanical components.

Tips for achieving optimal motor operation include implementing predictive maintenance protocols, which can help identify potential issues before they lead to downtime. Additionally, utilizing variable frequency drives can optimize energy consumption by adjusting motor speed based on actual load requirements. This not only improves overall efficiency but also contributes to lower operational costs.

Another effective strategy is the integration of IoT technology for real-time monitoring and control. This allows operators to gather performance data and adjust parameters accordingly, ensuring that the motors operate within their ideal performance ranges. By leveraging these advanced control solutions, industries can unlock greater productivity while maintaining sustainability goals.

Top Motor and Control Solutions for Enhanced Efficiency and Performance

This chart displays the efficiency levels and performance metrics of various motor control solutions. The data reflects the average efficiency percentage and performance ratings based on real-world applications.

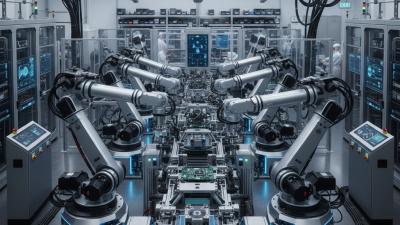

Applications of Enhanced Motors in Various Industries

Enhanced motors play a crucial role in optimizing efficiency and performance across various industries. In manufacturing, for example, these advanced motors can be integrated into robotic systems, leading to improved precision and speed during production processes. This results not only in higher output but also in reduced energy consumption, aligning with the growing emphasis on sustainable practices. By utilizing these motors, manufacturers can minimize downtime and significantly decrease operational costs.

In the renewable energy sector, enhanced motors are pivotal in wind and solar applications. In wind turbines, they transform wind energy into electrical energy with remarkable efficiency. Similarly, in solar energy systems, these motors ensure that solar panels are optimally positioned to catch the maximum sunlight, thus boosting energy generation. This technology is not only about enhancing performance but also about embracing eco-friendly solutions and contributing to a more sustainable future.

**Tips:** When considering the implementation of enhanced motors in your operations, focus on energy efficiency ratings and compatibility with existing systems. Regular maintenance schedules can also prolong the lifespan of these motors, ensuring consistent performance over time. Additionally, training staff on the benefits and functionalities of these motors can maximize their potential in your specific applications.

| Industry | Motor Type | Control Solution | Efficiency (%) | Performance Metric |

|---|---|---|---|---|

| Manufacturing | AC Induction Motor | VFD (Variable Frequency Drive) | 95 | Torque Output (Nm) |

| Transportation | Permanent Magnet Synchronous Motor | Field-Oriented Control | 90 | Speed (RPM) |

| Agriculture | Brushless DC Motor | PID Control | 97 | Efficiency Metric |

| HVAC | EC Motor (Electronically Commutated) | Smart Control Systems | 99 | Energy Consumption (kWh) |

| Renewable Energy | Wind Turbine Motor | MPPT Control (Maximum Power Point Tracking) | 85 | Output Power (kW) |

Related Posts

-

Comprehensive Guide to Optimizing Your Motor and Control Solutions for Enhanced Efficiency

-

Understanding the Future of Motors and Controls in Sustainable Technology

-

Why Motor and Control Solutions Are Essential for Modern Automation Systems

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency

-

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

-

How to Choose the Right Circuit Breakers for Your Home and Business Needs