Why Motor and Control Solutions Are Essential for Modern Automation Systems

In today's rapidly evolving industrial landscape, the integration of motor and control solutions is crucial for the efficiency and effectiveness of modern automation systems. According to a report by MarketsandMarkets, the global market for industrial automation is projected to reach $295.69 billion by 2025, driven by rising demand for improved operational efficiency and precision in manufacturing processes. Motor and control solutions play a fundamental role in this transformative journey, providing the necessary framework to enhance productivity across various sectors, including automotive, food and beverage, and electronics.

The deployment of advanced motor and control solutions is not just a trend; it is becoming a necessity for businesses aiming to maintain competitiveness in a digital age. A recent survey from the International Society of Automation (ISA) highlighted that 70% of businesses plan to invest in smart manufacturing technologies, including sophisticated motor control systems, to facilitate real-time monitoring and data analytics. This commitment underscores the importance of reliable and adaptable motor and control solutions in achieving seamless automation, optimizing energy efficiency, and reducing operational risks in an increasingly automated world.

The Role of Motors in Modern Automation Systems

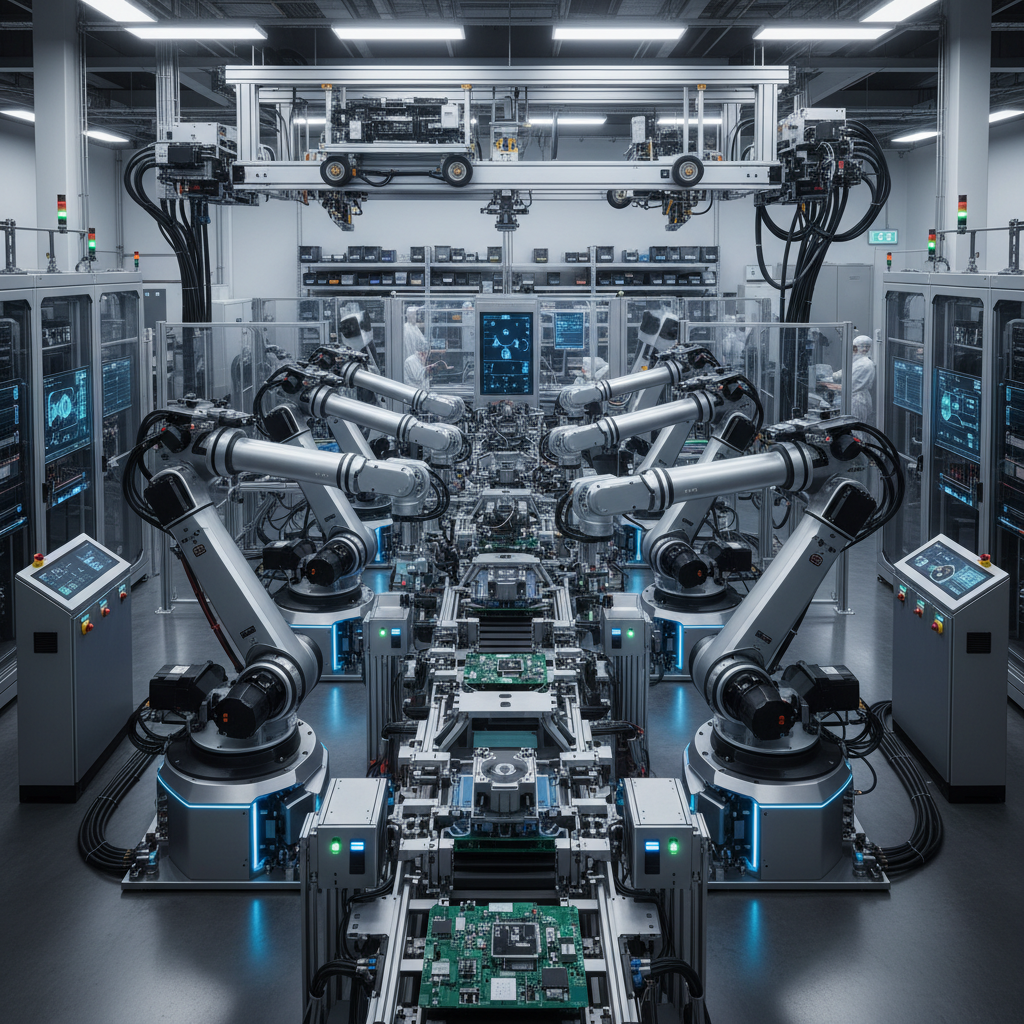

In modern automation systems, motors play a crucial role by providing the necessary mechanical power to drive various processes. These electric motors are the backbone of automation, enabling machines to perform complex tasks with precision and efficiency. From conveyor belts to robotic arms, motors control the motion and speed of equipment, allowing for seamless operations in manufacturing, packaging, and assembly lines. The advancement of motor technology, including brushless and stepper motors, has further enhanced performance, reliability, and energy efficiency, making them indispensable in today’s industrial landscape.

Moreover, the integration of motors within control solutions enhances their functionality, ensuring that automation systems can be easily monitored and adjusted. This synergy allows operators to optimize performance, reduce downtime, and implement real-time adjustments based on system demands. As industries increasingly embrace smart technologies and the Internet of Things (IoT), the role of motors will continue to evolve, providing the horsepower behind innovations that increase productivity and reduce operational costs. Without robust motor solutions, modern automation systems would struggle to meet the demands of efficiency and scalability in a rapidly changing market.

Types of Control Solutions for Enhanced Automation Efficiency

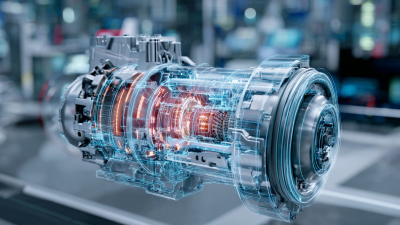

In the rapidly evolving landscape of automation, the significance of advanced motor and control solutions cannot be overstated. The International Society of Automation (ISA) projects that the automation sector will reach a market size of $296.70 billion by 2026, highlighting the demand for efficient and precise control systems. Among the various control technologies, PID (Proportional-Integral-Derivative) controllers remain a staple due to their reliability in maintaining system stability. With their ability to reduce process variability, they play a vital role in sectors such as manufacturing and aerospace, where precision is paramount.

Another noteworthy innovation is the advent of programmable logic controllers (PLCs) and industrial PCs, which enhance the scalability and flexibility of automation systems. According to a report by MarketsandMarkets, the PLC market alone is expected to grow from $10.33 billion in 2020 to $14.63 billion by 2025. This growth indicates a shift toward more complex control solutions that can easily integrate with IoT technologies. By leveraging these advancements, industries can optimize operations, improve response times, and ultimately drive efficiency, setting the stage for a more automated future.

Integration of Motor and Control Solutions in Industrial Applications

The integration of motor and control solutions in industrial applications is pivotal for enhancing efficiency and productivity in modern automation systems. Motors serve as the driving force behind various machinery, while control solutions ensure precise management of these motors to optimize performance. Together, they create a seamless synergy that allows for the smooth operation of automated processes, ultimately reducing downtime and increasing overall operational throughput.

Furthermore, the adaptability of motor and control solutions plays an essential role in meeting the diverse demands of different industries. Whether it's in manufacturing, logistics, or energy, these integrated systems can be customized to suit specific applications. Advanced control algorithms enable real-time adjustments based on varying load conditions or operational requirements, ensuring that machinery operates at peak efficiency. As industries evolve and seek to implement smart manufacturing processes, the role of motor and control solutions will continue to grow, driving innovation and facilitating the transition to more automated environments.

Benefits of Advanced Motor and Control Technologies for Automation

Advanced motor and control technologies play a crucial role in enhancing the efficiency and reliability of modern automation systems. According to a report by the International Society of Automation, the implementation of smart motor control solutions can lead to energy savings of up to 50%. This drastic reduction in energy consumption is vital for industries aiming to decrease operational costs while minimizing their environmental footprint. As automation continues to expand across various sectors, the demand for sophisticated motor and control solutions has never been more pronounced.

Furthermore, the integration of advanced motor control technologies enhances system responsiveness and flexibility. A study from the National Electrical Manufacturers Association reveals that automated systems using high-performance motor drives can increase production throughput by 20-30%. This boost in productivity is largely attributed to improved acceleration and deceleration rates, which allow for more precise control over machinery. With manufacturers under constant pressure to optimize processes and output, investing in these advanced technologies is essential for maintaining competitive advantage in today's fast-paced market.

| Dimension | Description | Benefits |

|---|---|---|

| Energy Efficiency | Advanced motor technologies reduce energy consumption. | Lower energy costs and reduced carbon footprint. |

| Precision Control | Enhanced algorithms provide precise control of motors. | Improved product quality and consistency. |

| Scalability | Easily adaptable to changing production needs. | Faster response to market demands. |

| Reliability | Robust designs minimize downtime and maintenance. | Increased overall productivity. |

| Intelligence | Integration with IoT for real-time data access. | Better decision-making and predictive maintenance. |

| Compact Design | Reduced size of motors saves valuable space. | More efficient use of factory floor space. |

Future Trends in Motor and Control Solutions for Automation Systems

The future of motor and control solutions in automation systems is set to be transformative, driven by advances in technology and the increasing demand for efficient and responsive systems. The global market for flight control systems is expected to grow significantly, illustrating the broader trend of automation across various sectors. By 2032, it is projected to reach $571.8 billion, marking a robust annual growth rate of 8.08%. This growth reflects the need for sophisticated solutions that enhance operational efficiency and meet the automation challenges of tomorrow.

As embedded systems become integral to more applications—from consumer electronics to industrial automation—designers face new considerations. Future automation systems will rely on advanced real-time and networked embedded solutions, which can provide enhanced connectivity and intelligence. Tips for professionals in this field include staying informed on the latest innovations in embedded technology and investing in flexible, scalable solutions that can adapt to the evolving landscape of automation. Embracing these trends will not only drive individual project success but also contribute to the overall advancement of industrial automation systems.

Related Posts

-

Comprehensive Guide to Optimizing Your Motor and Control Solutions for Enhanced Efficiency

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency

-

Understanding the Future of Motors and Controls in Sustainable Technology

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

10 Essential Tips for Choosing the Right Soft Start Motor Starter

-

How to Choose the Right Circuit Breakers for Your Electrical System Needs