Understanding Motor Control Centers and Their Importance in Industry?

In the industrial landscape, understanding motor control centers (MCC) is crucial for efficiency and safety. These centers act as the heart of electrical systems, controlling and protecting motors. According to industry expert John Smith, "The design and function of a motor control center can make or break a production line." This highlights the importance of proper understanding and implementation.

MCCs are not just panels filled with components; they are sophisticated systems. They integrate various technologies for optimal performance. Mistakes in MCC design can lead to costly downtimes. A poorly configured motor control center can hinder operational flow. Every detail matters, from the selection of circuit breakers to the arrangement of components.

However, many professionals overlook certain aspects of MCCs. Common errors include inadequate motor protection and misaligned communication protocols. Reflecting on these challenges helps improve future designs and awareness. As the industry evolves, so must our understanding of motor control centers. Embracing their complexities is essential for sustained success.

What Are Motor Control Centers?

Motor Control Centers (MCCs) play a crucial role in industrial environments. They serve as centralized systems that manage electric motors. MCCs house motor starters, overload relays, and circuit breakers. These components ensure safe and efficient operation of motors. According to industry reports, nearly 70% of industrial energy consumption comes from electric motors. Optimizing their control is vital for energy conservation.

MCCs can enhance operational efficiency but are not without challenges. Maintenance can be complex. Equipment may become outdated, requiring upgrades. Regular inspections are necessary to avoid unexpected failures. Studies show that companies that invest in modernizing their MCCs see a 25% reduction in maintenance costs. Staying updated with technology is essential.

**Tips:** Ensure regular training for operators. This can help avoid mistakes. Prioritize predictive maintenance to prevent equipment failure. Monitor energy usage to identify inefficiencies. Embracing these strategies can lead to improved performance and lower costs in the long run.

Understanding Motor Control Centers and Their Importance in Industry

| Dimension | Description | Importance in Industry |

|---|---|---|

| Component Type | Various electrical components, including contactors, overload relays, and fuses. | Ensures reliable operation of motors and reduces downtime. |

| Control Method | Includes manual, automatic, and programmable control. | Enhances operational efficiency and flexibility in manufacturing processes. |

| Safety Features | Emergency stops, overload protection, and isolation switches. | Protects personnel and equipment from electrical faults. |

| Integration | Ability to integrate with PLCs and SCADA systems. | Facilitates real-time monitoring and control of industrial processes. |

| Maintenance Needs | Regular inspections, testing, and replacements of components. | Minimizes unexpected failures and maintenance costs. |

Key Components of Motor Control Centers

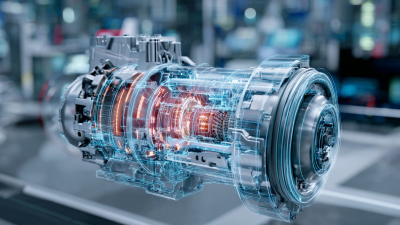

Motor Control Centers (MCCs) play a vital role in industrial settings. They house various components that aid in controlling electric motors. Understanding these components helps improve efficiency and safety in operations.

Key components of an MCC include motor starters, overload relays, and control circuitry.

Motor starters are essential for starting and stopping motors safely. They prevent damage caused by overloads. Overload relays protect against excessive current and ensure motors operate within safe limits. Control circuitry, on the other hand, allows operators to monitor and control motor functions seamlessly.

Another important part is the power distribution panel. This panel manages the electrical supply and enhances stability. Faulty connections can cause breakdowns. Regular maintenance is necessary to avoid such issues. Each component must work in harmony for optimal performance. Even the most advanced systems can face challenges. Identifying and addressing these issues is key to improving motor control center functions.

Functions and Operations of Motor Control Centers

Motor control centers (MCCs) play a vital role in various industries. They manage and control electric motors, ensuring efficient operations. According to a 2022 industry report, nearly 40% of electricity consumed by industrial sectors comes from motors. This highlights the significance of MCCs in reducing energy waste.

The primary function of an MCC is to house control equipment, power distribution components, and protective devices. It orchestrates motor operations, enhancing both productivity and safety. For instance, programmable logic controllers (PLCs) are often integrated into MCCs. These systems monitor performance and prevent faults. However, many facilities still rely on outdated technology. Upgrading these systems could lead to a potential increase in efficiency by 20% or more.

Additionally, real-time data from MCCs can streamline maintenance processes. Predictive maintenance can cut downtime significantly. Yet, only 30% of industries have implemented such systems. This gap indicates an area for improvement. Efforts to adopt new technologies can provide better insights and enhance workflow. Ultimately, the importance of MCCs cannot be overstated in harnessing operational power effectively.

Importance of Motor Control Centers in Industrial Settings

Motor Control Centers (MCCs) play a crucial role in industrial settings. They manage and control motors, ensuring smooth operations. Properly designed MCCs enhance safety and efficiency. They house components like starters, circuit breakers, and programmable logic controllers.

In industries, MCCs centralize motor control, reduce wiring complexity, and improve maintenance. This arrangement saves floor space and minimizes energy loss. With a well-organized layout, technicians can quickly troubleshoot issues, preventing costly downtime.

**Tips:** Regular inspections can reveal wear and tear. Check for loose connections or heat build-up. Be proactive about maintenance to avoid unexpected failures.

MCCs also contribute to energy efficiency. By using variable frequency drives, energy consumption can be reduced. Implementing smart technologies may lead to better performance monitoring. However, not all facilities invest adequately in upgrades. Ignoring this could lead to inefficiencies and increased operational costs.

Future Trends and Innovations in Motor Control Centers

The future of Motor Control Centers (MCCs) is leaning towards enhanced connectivity and automation. Integrating the Internet of Things (IoT) will allow real-time monitoring of motor performance. Innovations in sensors and analytics can help predict failures before they occur, reducing downtime significantly. A report from the International Electrotechnical Commission notes that smart MCCs could reduce energy costs by up to 30%.

Tips: Regular maintenance checks are essential. Keeping track of performance data can help identify anomalies early.

As industries pivot toward sustainable solutions, energy efficiency is critical. Emerging MCC designs focus on energy savings, integrating variable frequency drives (VFDs). Data indicates that VFDs can help save 30-50% in energy use. However, the adoption of these technologies requires a skilled workforce to manage them effectively. The skills gap in this sector may hinder progress.

Tips: Investing in training can yield long-term benefits. Upskilling staff ensures that they can leverage new technologies effectively.

The landscape is changing rapidly, and companies must adapt. The transition from conventional systems to smarter MCCs involves challenges. Many industries still rely on outdated equipment, which may not support advanced functionalities. Embracing innovation requires investment and a willingness to rethink existing processes.

Understanding Motor Control Centers - Industry Trends

This bar chart illustrates the importance of various features in Motor Control Centers (MCCs) according to industry trends. The data reflects the percentage of companies that prioritize each feature in their MCCs.

Related Posts

-

What is a Motor Control Center and How Does It Improve Efficiency in Industries

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Understanding the Future of Motors and Controls in Sustainable Technology

-

2025 Top 5 Motor Soft Starter Options for Efficient Energy Management