Why Do You Need an Electric Motor Controller for Your Project?

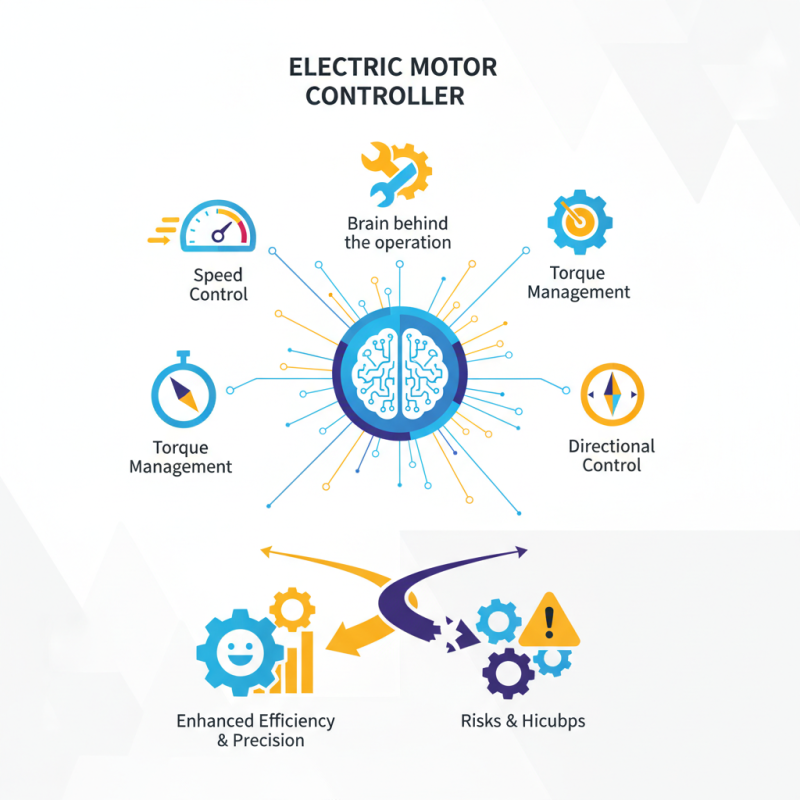

In the realm of electric motor technology, the importance of an effective electric motor controller cannot be overstated. Experts like Dr. Sarah Johnson remind us, “An electric motor controller is the brain behind the operation; it translates commands into action.” This statement encapsulates the essential role these controllers play in shaping performance and efficiency.

When embarking on any project involving electric motors, the selection of an appropriate controller is crucial. A well-chosen electric motor controller can greatly enhance efficiency and precision. In contrast, a poor choice may lead to unexpected risks and performance hiccups. It’s vital to analyze your needs before making a selection.

Consider that an electric motor controller impacts speed, torque, and direction. Without it, managing these factors can be cumbersome. Reflecting on the complexities of control systems encourages users to deeply understand their project requirements. In the world of electric motors, precision matters. Taking the time to choose wisely pays dividends in the long run.

Understanding the Basics of Electric Motor Controllers

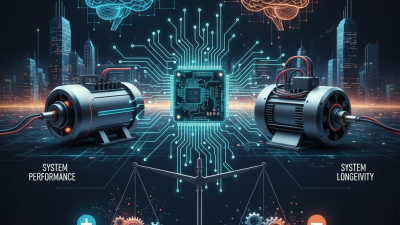

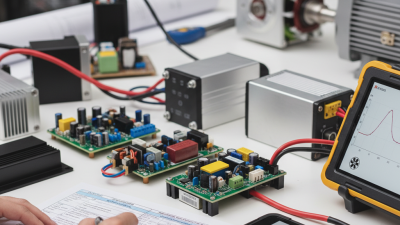

Electric motor controllers play a vital role in modern projects involving motors. They regulate the power sent to the motor, which directly impacts performance. By controlling voltage and current, these devices ensure motors run efficiently. They enable smooth acceleration and deceleration. This enhances the overall user experience.

The vast array of electric motor controllers can be confusing. Options include PWM (Pulse Width Modulation) and linear controllers. Not every type fits every project. You may need to experiment to find the right one. This trial and error process can be frustrating. However, understanding your specific needs can simplify this journey.

A basic grasp of electric motor controllers can lead to better project outcomes. They not only help in controlling speed but also in optimizing energy consumption. Faulty controllers can lead to motor damage. This emphasizes the need for careful selection. As you dive deeper into this subject, you will refine your understanding and improve your project results. Learn through mistakes; it's part of the process.

Why Do You Need an Electric Motor Controller for Your Project? - Understanding the Basics of Electric Motor Controllers

| Feature | Description | Importance |

|---|---|---|

| Speed Control | Regulates the speed of the electric motor effectively. | Allows precise control over the motor's operation. |

| Current Limiting | Protects the motor from drawing excessive current. | Prevents overheating and potential damage. |

| Direction Control | Allows the motor to run forward or backward. | Essential for applications requiring bidirectional movement. |

| Efficiency | Enhances overall efficiency of the motor operation. | Reduces energy wastage, leading to cost savings. |

| Thermal Protection | Monitors temperature to prevent overheating. | Ensures longevity and reliability of the motor. |

| Integration | Can be integrated with various control systems. | Enhances versatility for different applications. |

Key Functions and Benefits of Electric Motor Controllers

Electric motor controllers are crucial in various applications. They enhance

efficiency, provide precise control, and ensure safety. According to recent industry reports, around

60% of energy consumption in industrial sectors comes from electric motors.

Without controllers, this power could be wasted. These devices manage motor speed, torque, and direction

with precision.

One significant benefit is improved energy efficiency. Research shows that using electric motor

controllers can lead to energy savings of up to 30%. This reduction not only helps businesses

save money but also supports sustainability efforts. Precise control over the motor's performance can also

prevent overheating and extend its lifespan. However, many projects overlook this aspect, leading to

premature failures or inefficiencies.

Electric motor controllers also offer advanced features like regenerative braking.

This technology allows motors to recover energy during deceleration. Yet, not all projects implement this,

often missing out on substantial energy savings. Moreover, the complexity of integration can be a hurdle.

Engineers may find themselves grappling with compatibility issues. Nonetheless, the potential benefits

far outweigh these challenges. Embracing electric motor controllers is essential for

modern engineering projects.

Types of Electric Motor Controllers and Their Applications

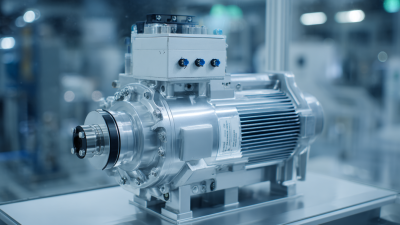

Electric motor controllers play a crucial role in various applications. They manage the speed, torque, and direction of electric motors. Understanding different types of controllers is key for effective project planning.

There are several types of electric motor controllers. DC motor controllers are popular in robotics. They offer straightforward control of speed and direction. Their simplicity makes them easy to use, though they can lack advanced features. AC motor controllers, like variable frequency drives (VFDs), are essential for industrial applications. They provide efficient power control, but they might be overkill for small projects.

Servo motor controllers are vital for precision tasks. They enable accurate position control. Nonetheless, they can be complex and costly to integrate. Choosing the right controller depends on the project’s specific needs. The wrong choice can lead to performance issues and wasted resources. It's a decision that requires careful consideration and reflection.

Factors to Consider When Choosing an Electric Motor Controller

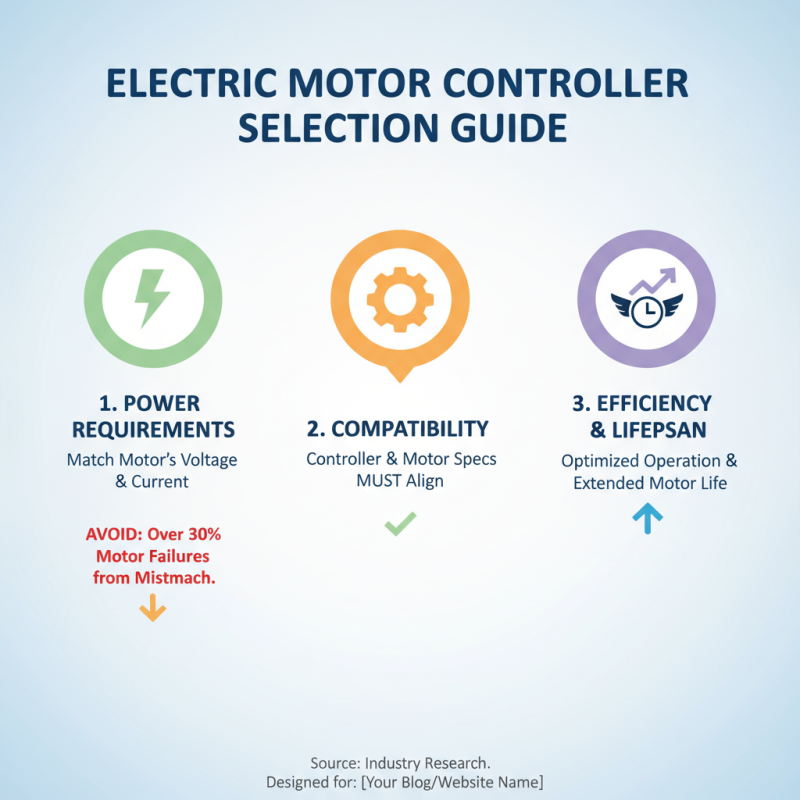

When selecting an electric motor controller, several key factors come into play. Understanding the power requirements of your project is critical. Research shows that over 30% of motor failures stem from improper power matching. Choose a controller that matches the motor's voltage and current specifications. This ensures efficient operation and prolongs the lifespan of your motor.

The type of control method is also essential. You can opt for open-loop or closed-loop systems. Open-loop systems are simpler and often less expensive. However, they may lack precision. In contrast, closed-loop systems provide more accuracy. They ensure feedback and can adapt to varying load conditions. This is vital for applications requiring precise speed control.

Another aspect to consider is thermal management. A controller needs to dissipate heat efficiently. Data from industry reports indicates that overheating can reduce performance by up to 20%. Look for controllers with built-in thermal protection features. This can prevent damage and improve reliability. Lastly, consider the size and form factor. Space constraints may necessitate a compact design without compromising functionality.

Common Challenges and Solutions in Electric Motor Control Systems

Electric motor control systems face various challenges. Overheating is a common issue. A study by the Electric Power Research Institute revealed that up to 30% of motor failures are due to excessive heat. Ensuring proper heat dissipation and temperature monitoring can prevent this.

Another challenge is precise speed control. Motors often need to operate at varying speeds for efficiency. Inconsistent power supply can lead to unstable performance. Researchers found that implementing advanced PID controllers can improve speed stability by 40%. This approach allows for better responsiveness to load changes.

Communication between the controller and the motor is crucial. Signal interference can cause errors in performance. Studies indicate that poor wiring and environmental factors often contribute to this problem. Shielded cables and robust connections can mitigate these issues. Maintaining clear communication is vital for optimal operation.

Related Posts

-

Top 10 Electric Motor Controllers You Should Consider?

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

How to Choose the Right Electric Motor Controller for Your Project?

-

What is Motor Control and How Does It Impact Movement?

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency

-

Exploring Electric Motor Controller Innovations at the 2025 China 138th Canton Fair