Why Do You Need a Soft Starter for Your Electrical Motor System?

In the world of electrical motor systems, managing start-up efficiency is critical. A soft starter plays a vital role in achieving this. According to a report by the International Energy Agency, improper motor starts can cause up to a 40% increase in energy consumption. Implementing a soft starter can mitigate these issues by reducing the inrush current, which protects against mechanical wear and prolongs motor life.

Industry expert Dr. Michael Smith has noted, "Using a soft starter is essential for any operation aiming for reliability and efficiency." His insight highlights a common industry acknowledgment of the benefits soft starters provide. They not only enhance energy efficiency but also minimize the risk of damage to motor systems during harsh start conditions.

Many businesses overlook the importance of these devices. Without a soft starter, motors may face excessive stress, leading to costly downtime. It’s crucial for companies to reflect on their operational practices and consider integrating a soft starter to ensure longevity and efficiency in their electrical systems.

The Functionality of Soft Starters in Electrical Motor Systems

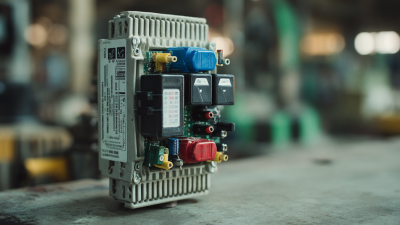

Soft starters are essential for managing electrical motor systems effectively. They gradually ramp up the current supplied to the motor, reducing the initial torque. This approach prevents sudden stress on mechanical components. As a result, wear and tear on gears and bearings is minimized. A soft starter can also lower the electrical load during startup, protecting both the motor and the wiring.

Implementing soft starters helps in reducing energy consumption during startup phases. When motors start abruptly, they consume a significant amount of energy. In contrast, soft starters control this energy use, providing a smoother experience. This often leads to increased longevity of the motor and enhances overall efficiency.

Sometimes, soft starters can complicate the system. Their installation may require time and expertise. If not deployed correctly, they can lead to operational issues. It's crucial to reflect on whether the addition of a soft starter aligns with the specific needs of your motor system. Conducting thorough assessments can help determine their real benefits.

Benefits of Using Soft Starters for Motor Efficiency and Longevity

Soft starters play a crucial role in enhancing motor efficiency and longevity. By gradually ramping up the motor speed, they reduce the inrush current, which can be up to six times the normal operating current. This gradual increase limits wear and tear on the motor and electrical components. Over time, this not only saves energy but extends the overall lifespan of the motor system.

When using soft starters, monitor the temperature of your motor regularly. High temperatures can signal potential issues. Adjust settings if needed, based on the motor's operating conditions. Also, remember to check the wiring and connections frequently. Proper connections reduce resistance, leading to better performance.

Consider implementing time delays for start and stop functions. This can streamline operations during peak load times, ensuring efficiency. Such simple tweaks can significantly improve overall performance and reliability. A soft starter may seem like a small addition, but its impact is substantial. Often, we overlook the value of controlled starts; making this change can highlight areas for improvement.

Common Applications of Soft Starters in Industrial Settings

Soft starters play a vital role in industrial settings, primarily by facilitating smoother starts for electric motors. They help mitigate issues like mechanical stress and electrical spikes. In applications where heavy machinery is used, a soft starter can reduce initial inrush current by up to 50%. This ensures that both the motor and the connected load experience less strain during startup.

Common applications for soft starters include conveyors, fans, and pumps. For example, in a water treatment facility, soft starters are employed to prevent sudden water hammer effects. This can lead to less wear and tear on pipes, ultimately saving maintenance costs. In manufacturing plants, using soft starters can enhance equipment lifespan and improve overall energy efficiency. According to industry reports, soft starters can save up to 30% in energy costs compared to direct-on-line starting.

Tips: Regularly review the soft starter settings based on load requirements. Ensure proper installation to avoid issues. Educate your team about the benefits to maximize efficiency. This promotes a culture of proactive maintenance. Remember, each application might need specific configurations. Don't overlook manufacturer guidelines.

Common Applications of Soft Starters in Industrial Settings

Comparison Between Soft Starters and Other Motor Control Devices

When it comes to controlling electrical motors, soft starters offer unique advantages over traditional motor control devices. Unlike direct-on-line starters, which apply full voltage instantly, soft starters gradually ramp up the voltage. This reduces inrush current, which can reach up to 600% of full load current. The reduced starting current minimizes stress on electrical components and enhances the motor's lifespan. Reports indicate that using a soft starter can extend motor life by as much as 50%.

Various motor control devices exist in the market. Variable frequency drives (VFDs) are among them, but they are often more complex and expensive to implement. While VFDs allow for speed control, soft starters focus strictly on the starting process. They are simpler and cheaper. Research shows that over 20% of businesses would benefit from installing soft starters instead of VFDs, depending on their operational needs.

Choosing the right device can be overwhelming. Soft starters can be inadequate in applications requiring precise speed control. It's essential to evaluate your specific needs. Not every application will benefit from the features of a soft starter. Failures can occur if not properly assessed.

Installation and Maintenance Considerations for Soft Starters

When considering soft starters for electrical motor systems, installation and maintenance play a vital role. Proper installation ensures that the soft starter integrates seamlessly with the motor and controls. It's essential to follow the manufacturer's guidelines closely. Mistakes during installation can lead to inefficiencies or equipment damage. Good placement can minimize cable lengths and electrical noise.

Regular maintenance is equally important. Checking connections and settings can prevent unexpected failures. Dust accumulation on components should be addressed promptly. Additionally, periodic testing of the control system helps ensure reliability. Some users might overlook this step, thinking that everything is functioning well. However, neglecting these maintenance checks can lead to a system breakdown. Being proactive is key to extending the life of both the soft starter and the motor. It might seem tedious, but the effort pays off in performance and longevity.

Why Do You Need a Soft Starter for Your Electrical Motor System? - Installation and Maintenance Considerations for Soft Starters

| Dimension | Description | Importance |

|---|---|---|

| Voltage Rating | The maximum voltage the soft starter can handle. | Ensures compatibility with the electrical system voltage. |

| Current Rating | The max current to which the soft starter can respond. | Prevents overheating and component failure. |

| Starting Method | Soft starters may use various methods like Voltage Ramp. | Reduces mechanical stress on the motor and load. |

| Control Options | Various control methods like manual or automatic settings. | Provides flexibility in starting and stopping processes. |

| Protection Features | Include overload, short circuit, and phase failure protections. | Enhances safety and longevity of the motor and system. |

| Installation Ease | How straightforward it is to install the soft starter. | Aids in reducing downtime during setup. |

| Maintenance Requirements | Frequency and type of maintenance needed. | Ensures optimal performance and reliability over time. |

Related Posts

-

Understanding Soft Starters: The Key to Smooth Motor Operation and Enhanced Energy Efficiency

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications

-

Exploring the Future: Motor Starters at the 138th Canton Fair 2025 and Industry Trends

-

What is a Motor Control Center and How Does It Improve Efficiency in Industries

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications