How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

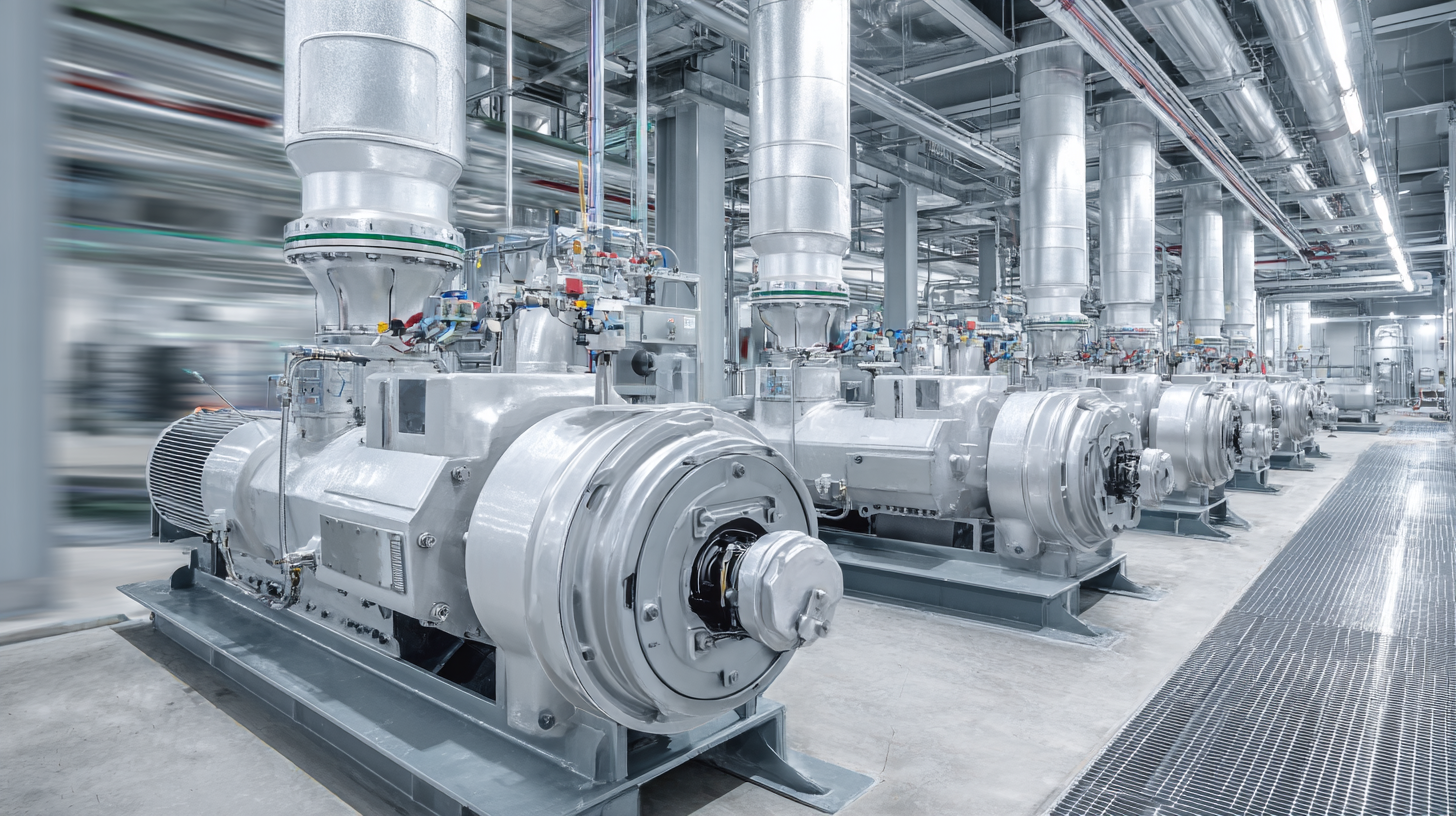

In the pursuit of maximizing energy efficiency, optimizing electric motor controller performance has become a critical focus for industries reliant on electric motors. According to a report by the International Energy Agency (IEA), electric motors are responsible for approximately 45% of global electricity consumption within industrial applications. With the increasing demand for energy efficiency and sustainability, enhancing the functionality of electric motor controllers can lead to significant reductions in energy usage, operational costs, and greenhouse gas emissions.

In the pursuit of maximizing energy efficiency, optimizing electric motor controller performance has become a critical focus for industries reliant on electric motors. According to a report by the International Energy Agency (IEA), electric motors are responsible for approximately 45% of global electricity consumption within industrial applications. With the increasing demand for energy efficiency and sustainability, enhancing the functionality of electric motor controllers can lead to significant reductions in energy usage, operational costs, and greenhouse gas emissions.

Furthermore, the U.S. Department of Energy (DOE) estimates that improving motor systems, which includes optimizing electric motor controllers, can yield energy savings of up to 20%. Given these statistics, it is essential for engineers and facility managers to adopt best practices in optimizing electric motor controller performance to remain competitive and environmentally responsible in today's market.

Identifying Key Factors Affecting Electric Motor Controller Efficiency

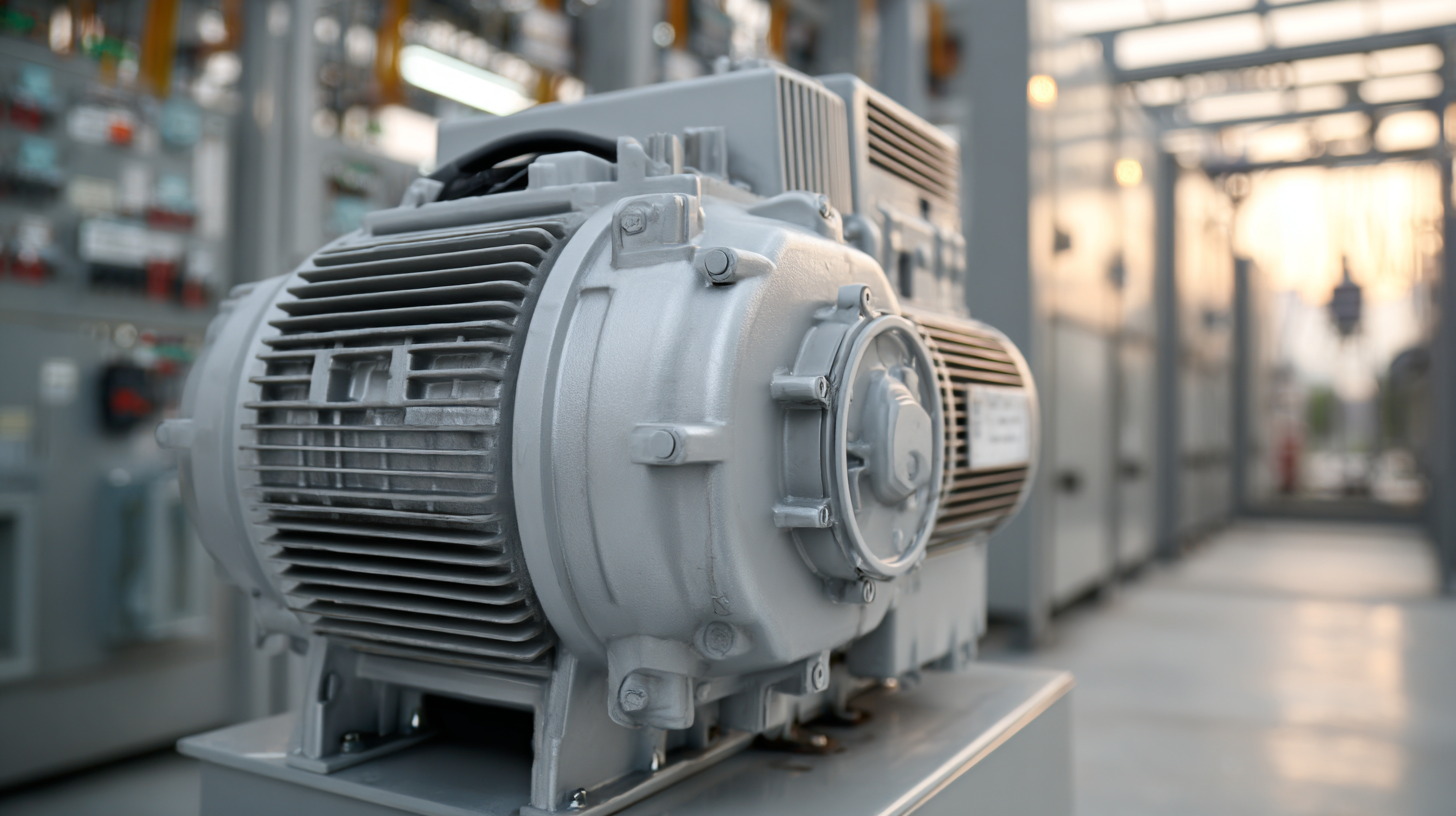

Electric motor controllers play a crucial role in determining the overall

energy efficiency of electric motors. Several key factors influence the efficiency of these controllers.

One significant element is the quality of power electronics used in the design. High-performance transistors, such as

silicon carbide (SiC) devices, have been shown to reduce energy losses by up to 50% compared to traditional silicon-based transistors.

According to a report by the International Energy Agency (IEA), improving power electronics can lead to a potential increase in efficiency ratings, which can enhance overall system performance significantly.

Electric motor controllers play a crucial role in determining the overall

energy efficiency of electric motors. Several key factors influence the efficiency of these controllers.

One significant element is the quality of power electronics used in the design. High-performance transistors, such as

silicon carbide (SiC) devices, have been shown to reduce energy losses by up to 50% compared to traditional silicon-based transistors.

According to a report by the International Energy Agency (IEA), improving power electronics can lead to a potential increase in efficiency ratings, which can enhance overall system performance significantly.

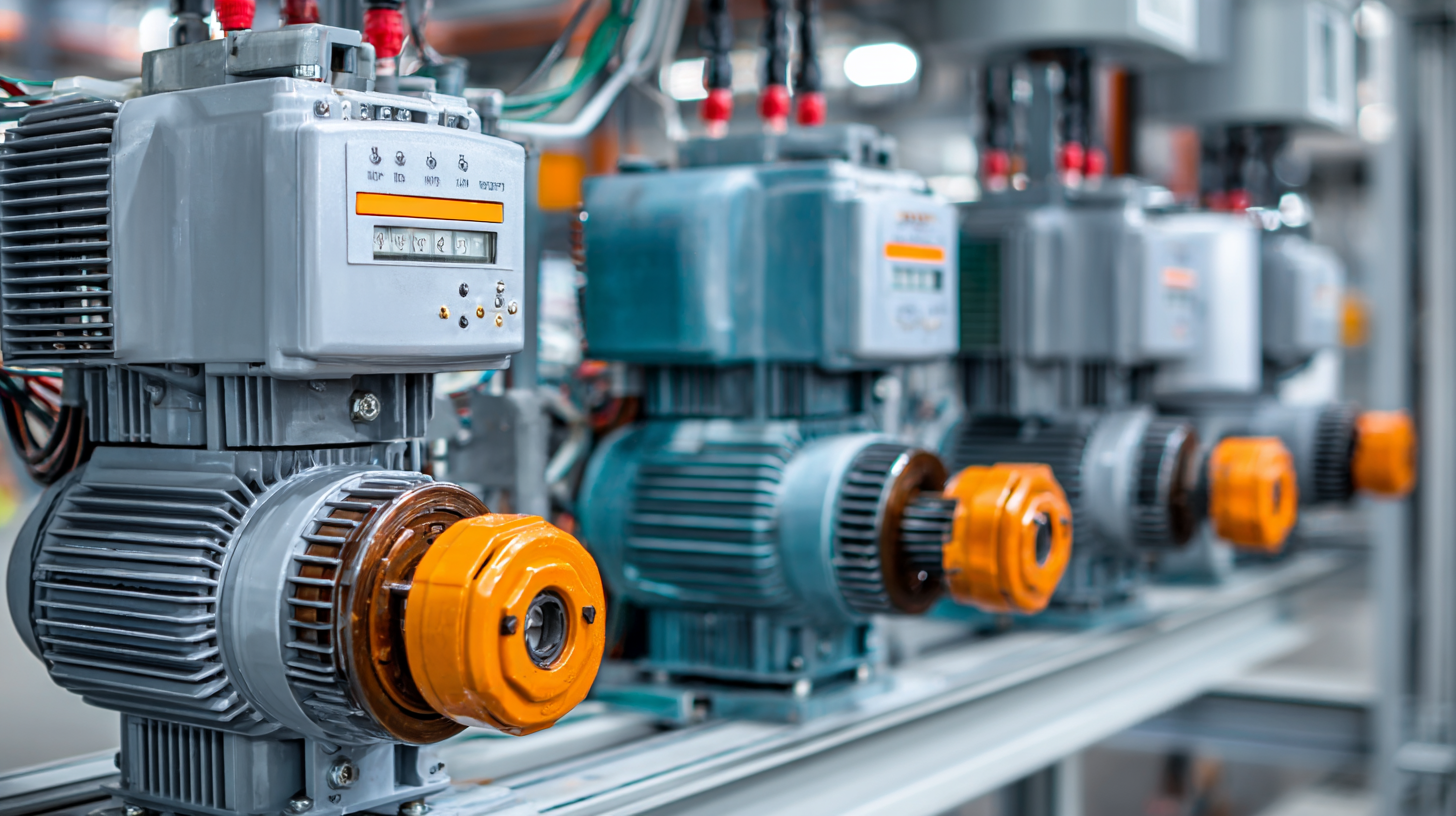

Another critical factor is the control algorithm implemented within the motor controller. Advanced algorithms, such as model predictive control (MPC) and field-oriented control (FOC), optimize the motor's operation by adapting to varying load conditions. Research from the Electric Power Research Institute (EPRI) indicates that employing sophisticated control strategies can improve energy efficiency by 10–20% in industrial applications. Moreover, thermal management also plays a vital role; ensuring that controllers operate within optimal temperature ranges can prevent energy losses and extend system longevity, further contributing to efficiency gains.

Selecting the Right Controller Architecture for Energy Optimization

Selecting the right controller architecture is crucial for optimizing the efficiency of electric motor systems. According to a report by the International Energy Agency (IEA), motors account for approximately 45% of global electricity consumption in industrial applications. Thus, implementing advanced control strategies can lead to significant energy savings. For instance, adopting field-oriented control (FOC) enables precise control of motor torque and flux, enhancing performance and efficiency, particularly in variable-speed applications.

Furthermore, the choice of architecture—whether it be a digital, analog, or hybrid controller—plays a vital role in energy optimization. A study published in the IEEE Transactions on Industrial Electronics highlighted that digital controllers, with their ability to process complex algorithms in real-time, can improve overall energy efficiency by up to 20% compared to traditional analog systems. This shift allows for better integration with modern sensors and IoT devices, facilitating smart grid applications. By selecting an appropriate controller architecture, manufacturers can not only reduce operational costs but also contribute to greener energy practices in the long run.

Energy Efficiency of Different Electric Motor Controllers

Implementing Advanced Control Algorithms to Enhance Performance

Implementing advanced control algorithms is crucial for enhancing the performance of electric motor controllers, particularly in striving for maximum energy efficiency. Modern algorithms, such as model predictive control (MPC) and fuzzy logic, offer adaptability to changing operational conditions, optimizing the torque and speed of electric motors. According to a report by the International Energy Agency, optimizing control strategies can lead to energy savings of up to 30% in industrial applications, significantly lowering operational costs and reducing carbon footprints.

Tips for Optimization: Regularly update control algorithms to align with the latest technological advancements. Experimenting with machine learning models can also facilitate predictive maintenance, ultimately prolonging the lifespan of equipment and improving performance metrics. Additionally, ensure that sensor data is accurately calibrated to provide real-time feedback for more responsive control actions.

Incorporating advanced techniques like artificial intelligence into control systems allows for dynamic adjustments based on environmental factors, boosting overall efficiency. Research from the IEEE Transactions on Industrial Electronics indicates that such integrations can improve system efficiency by approximately 15% compared to traditional control methods, making a compelling case for industries to invest in cutting-edge technology for their electric motors.

Regular Maintenance Practices to Sustain Motor Controller Efficiency

Regular maintenance practices are crucial for sustaining the efficiency of electric motor controllers. Conducting routine inspections can help identify potential issues before they escalate. This includes checking for loose connections, inspecting wiring for signs of wear or damage, and ensuring proper alignment of components. By addressing these small problems promptly, operators can prevent efficiency drops and costly repairs.

In addition to inspections, cleaning is an essential aspect of maintenance. Dust and debris can accumulate within the motor controller, interfering with heat dissipation and causing overheating. Regularly cleaning the housing and ensuring that ventilation paths are unobstructed can significantly enhance performance and lifespan. Furthermore, updating software and firmware as necessary helps to optimize functions and safeguards the system against compatibility issues, contributing to overall energy efficiency. By implementing these proactive maintenance practices, users can ensure that their motor controllers continue to operate at peak efficiency, maximizing energy savings and reducing operational costs.

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

| Maintenance Practice | Frequency | Impact on Efficiency (%) | Recommended Tools |

|---|---|---|---|

| Visual Inspection | Monthly | 5 | Inspection Checklist |

| Cleaning of Components | Quarterly | 10 | Compressed Air, Brushes |

| Lubrication of Moving Parts | Bi-annually | 8 | Lubricants, Grease Gun |

| Firmware Updates | Annually | 15 | Computer, Software |

| Electrical Connections Check | Semi-annually | 12 | Multimeter, Wrenches |

Utilizing Monitoring Tools for Real-Time Performance Assessment

Real-time performance assessment tools have become essential in various sectors, including electric motor controller optimization. Just as performance management tools allow companies to measure employee performance, integrating real-time monitoring systems in electric motor controllers provides valuable insights into operational efficiency. Utilizing such monitoring tools enables engineers to track energy consumption, operational parameters, and potential inefficiencies as they occur, facilitating prompt adjustments that lead to enhanced performance and energy savings.

Moreover, advancements in data collection and analysis have revolutionized how performance is evaluated across different fields. For instance, in educational settings, real-time performance data allows for the continuous monitoring of instructors' methods and students' progress, contributing to more effective learning experiences. Similarly, the implementation of real-time monitoring in electric motor systems can lead to proactive maintenance and immediate performance optimization, minimizing downtime and extending the lifespan of equipment. This integration of cutting-edge technology not only boosts energy efficiency but also supports the transition towards smarter, more sustainable industrial practices.

Related Posts

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications

-

Top Strategies for Maximizing Efficiency with Electrical Switch Innovations

-

7 Essential Tips for Optimizing Your Electric Motor VFD Efficiency

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits