Understanding the Role of 3 Phase Electric Motors in Modern Industrial Applications

In modern industrial applications, the significance of the 3 phase electric motor cannot be overstated, as it serves as a cornerstone for various machinery and automation systems. According to the International Electrotechnical Commission (IEC), approximately 70% of the electrical energy consumed in industrial settings is attributed to electric motors, with 3 phase electric motors making up a substantial portion of this consumption due to their efficiency and reliability. Recent reports from the U.S. Department of Energy indicate that the implementation of efficient motor systems can lead to energy savings of over 15%, emphasizing the critical role these motors play in reducing operational costs and carbon footprints.

Furthermore, as industries pivot towards sustainable practices, the demand for advanced 3 phase electric motors that integrate digital technologies is increasing, paving the way for innovations such as predictive maintenance and improved performance analytics. This evolution not only enhances productivity but also aligns with global energy efficiency goals, making the understanding of 3 phase electric motors essential for industry stakeholders.

Furthermore, as industries pivot towards sustainable practices, the demand for advanced 3 phase electric motors that integrate digital technologies is increasing, paving the way for innovations such as predictive maintenance and improved performance analytics. This evolution not only enhances productivity but also aligns with global energy efficiency goals, making the understanding of 3 phase electric motors essential for industry stakeholders.

The Importance of 3 Phase Electric Motors in Modern Industry

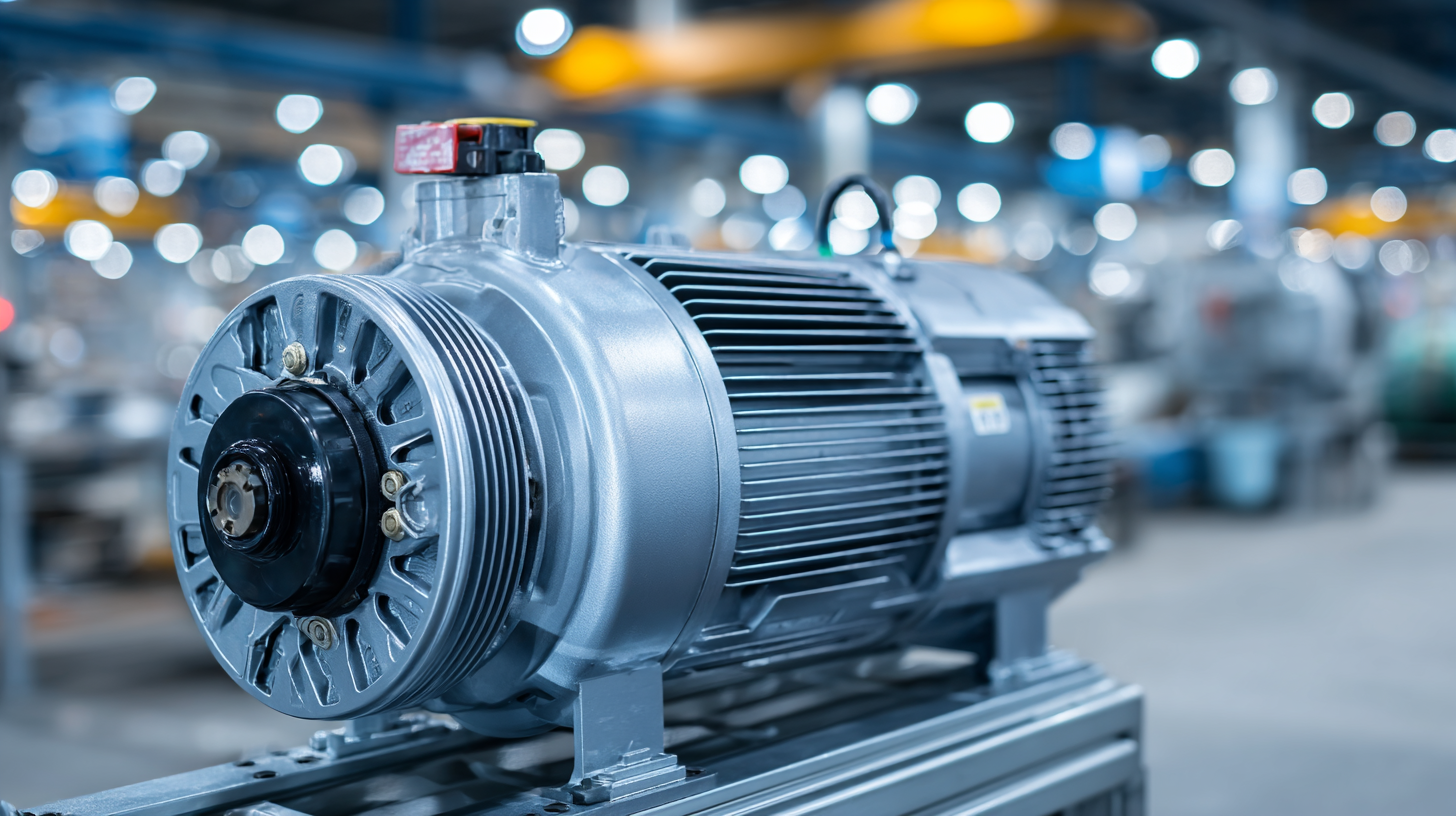

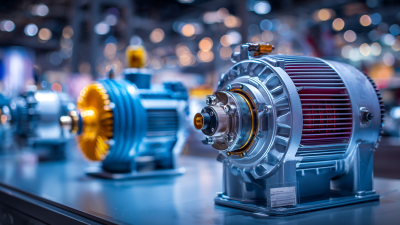

Three-phase electric motors play a crucial role in modern industrial applications due to their efficiency and reliability. These motors are widely used in various sectors, powering equipment such as conveyors, pumps, and compressors. Their ability to deliver constant torque and high starting torque makes them ideal for heavy-duty industrial operations. Moreover, energy regulations, such as the European Union's Ecodesign Regulation, emphasize the importance of high-efficiency standards for electric motors. This not only encourages industries to adopt more energy-efficient solutions but also aligns with global sustainability efforts.

Three-phase electric motors play a crucial role in modern industrial applications due to their efficiency and reliability. These motors are widely used in various sectors, powering equipment such as conveyors, pumps, and compressors. Their ability to deliver constant torque and high starting torque makes them ideal for heavy-duty industrial operations. Moreover, energy regulations, such as the European Union's Ecodesign Regulation, emphasize the importance of high-efficiency standards for electric motors. This not only encourages industries to adopt more energy-efficient solutions but also aligns with global sustainability efforts.

Tips: When selecting a three-phase motor for your application, consider factors such as motor efficiency ratings (e.g., IEC 60034-30) and the specific demands of your operation. Additionally, employing variable frequency drives (VFDs) can further enhance efficiency by allowing for precise speed control, ultimately reducing energy consumption and operational costs.

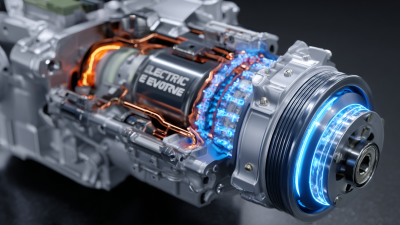

The ongoing advances in technology are also impacting the performance of three-phase motors. Innovations like AI-driven fault diagnosis and IoT-enabled monitoring systems are becoming increasingly popular. These approaches can help predict maintenance needs, ensuring that motors operate smoothly and reducing unexpected downtime. By integrating these technologies, industries can optimize their operations and respond swiftly to any potential issues.

Key Advantages of Using 3 Phase Motors Over Single Phase Models

Three-phase electric motors have become increasingly pivotal in modern industrial applications due to their superior performance and operational efficiency compared to single-phase models. The advantages of three-phase motors are particularly pronounced in scenarios requiring high power and continuous operation. According to a recent analysis, three-phase motors can be up to 30% more efficient than their single-phase counterparts, resulting in significant energy savings over time. This efficiency translates not only to lower operational costs but also supports sustainability initiatives in industrial operations, which is increasingly paramount in today's energy-conscious market.

Three-phase electric motors have become increasingly pivotal in modern industrial applications due to their superior performance and operational efficiency compared to single-phase models. The advantages of three-phase motors are particularly pronounced in scenarios requiring high power and continuous operation. According to a recent analysis, three-phase motors can be up to 30% more efficient than their single-phase counterparts, resulting in significant energy savings over time. This efficiency translates not only to lower operational costs but also supports sustainability initiatives in industrial operations, which is increasingly paramount in today's energy-conscious market.

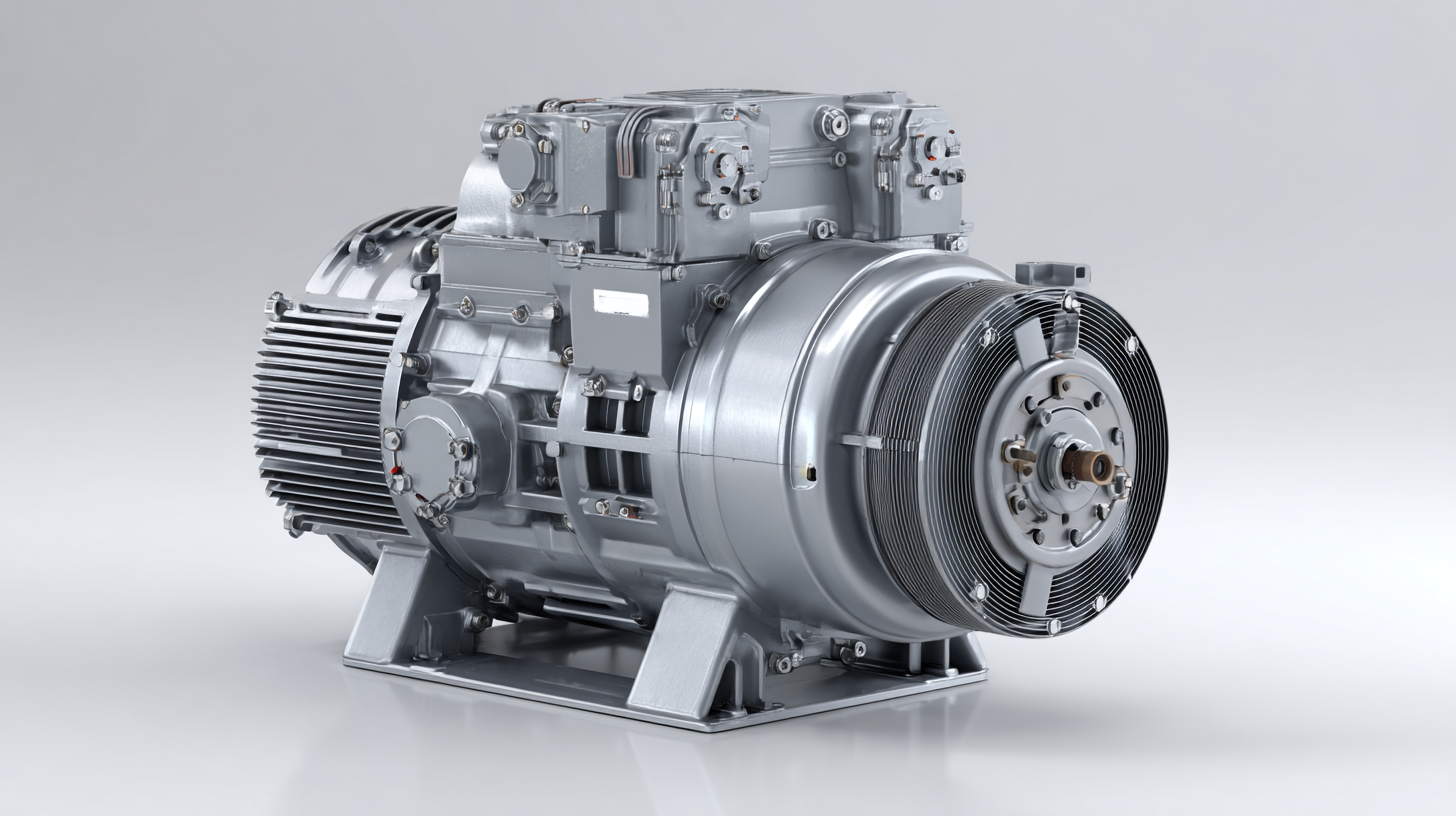

Moreover, the robustness of three-phase motors makes them ideal for demanding applications such as pump drives, conveyors, and automation systems. The capability to maintain a constant torque output while minimizing torque ripple enhances the overall performance of these motors. Recent advancements in torque control techniques, such as direct torque control (DTC) and adaptive control methods, further improve the stability and responsiveness of three-phase motors in real-time applications. These enhancements drive the adoption of three-phase motors in various sectors, including renewable energy systems, where optimized motor designs, like those for brushless DC motors, are crucial for efficiency in solar water-pumping applications and other green technologies.

Common Industrial Applications of 3 Phase Electric Motors

Three-phase electric motors play a crucial role in modern industrial applications due to their efficiency, reliability, and ability to handle substantial loads. Commonly found in manufacturing settings, these motors are integral to various processes, including pumps, conveyors, and compressors. Their ability to provide consistent torque and speed makes them suitable for continuous operation, which is essential in sectors like automotive production, oil and gas extraction, and HVAC systems.

In addition to traditional applications, three-phase motors are increasingly utilized in advanced technologies such as electric vehicles (EVs) and automated machinery. The growing demand for electric traction drives in EVs emphasizes the need for high-performance electric motors that can deliver smooth acceleration and deceleration. Furthermore, enhancements in motor control techniques, such as the use of variable frequency drives, have significantly improved the operational flexibility of three-phase induction motors, allowing for more nuanced speed control and energy efficiency. These advancements ensure that three-phase motors continue to be at the forefront of industrial innovation.

Understanding the Role of 3 Phase Electric Motors in Modern Industrial Applications

| Application | Motor Power (kW) | Efficiency (%) | Typical Voltage (V) | Control Method |

|---|---|---|---|---|

| Pumps | 5 - 500 | 85 - 95 | 380 - 480 | VFD |

| Conveyors | 1 - 250 | 80 - 90 | 380 - 480 | Direct On-Line |

| Fans and Blowers | 0.5 - 300 | 75 - 88 | 380 - 415 | VFD/Soft Start |

| Crushers | 30 - 600 | 85 - 95 | 380 - 690 | Direct On-Line |

| Mixers | 1 - 150 | 80 - 92 | 380 - 480 | VFD |

Tips for Selecting the Right 3 Phase Motor for Your Application

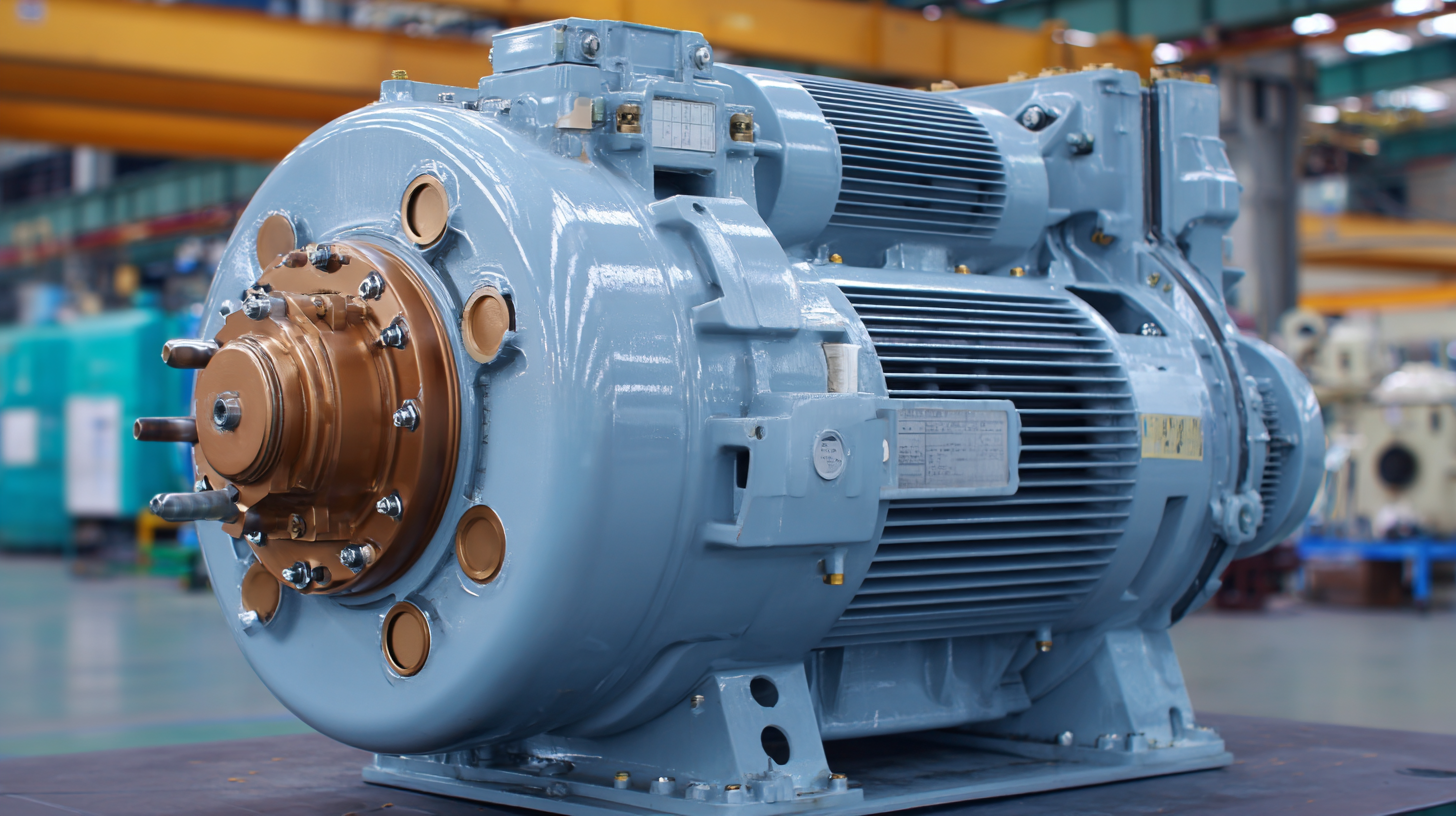

When selecting the right 3 phase electric motor for your application, various factors must be taken into account to ensure optimal performance and efficiency. According to the International Electrotechnical Commission (IEC), 3 phase motors represent approximately 90% of industrial electric motor applications globally, highlighting their critical role in manufacturing and production. The choice of motor type, whether it be a squirrel cage or a wound rotor design, can significantly influence energy consumption and overall system productivity.

Considerations such as the motor's efficiency class (IE1, IE2, IE3, or IE4) are crucial, as higher efficiency motors can result in considerable energy savings. The U.S. Department of Energy reports that upgrading to high-efficiency motors can lead to energy savings of 2% to 8%, which cumulatively can yield significant cost benefits over time. Additionally, it's essential to match the motor's power rating and torque characteristics to the specific requirements of your application, taking into account the load type, starting conditions, and operational environment. Proper selection not only enhances performance but also extends the lifespan of the motor, reducing maintenance costs and downtime.

Understanding the Role of 3 Phase Electric Motors in Modern Industrial Applications

This chart illustrates the efficiency levels of different types of 3 phase electric motors used in various industrial applications. The data represents typical efficiency percentages based on standard operating conditions.

Maintenance Best Practices for Ensuring Longevity of 3 Phase Motors

Proper maintenance of 3 phase electric motors is crucial for ensuring their longevity and efficiency in industrial applications. Regular inspections should be conducted to identify any wear and tear, such as bearing deterioration or insulation degradation. Keeping the motors clean and free from dust and debris helps prevent overheating and reduces the risk of electrical failure. Additionally, checking alignment and ensuring that the motor is properly mounted can minimize vibrations, which can cause mechanical damage over time.

Lubrication is another key aspect of maintenance that should not be overlooked. Using the correct type of lubricant and adhering to the manufacturer’s recommended schedules can significantly extend the life of the motor’s components. Monitoring operating temperatures and establishing a routine for testing electrical connections can preemptively address issues that could lead to more significant problems. Implementing these best practices can enhance the reliability of 3 phase motors, ensuring they operate optimally within various industrial settings.

Related Posts

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Exploring Electric Motors Innovations at the 2025 China Import and Export Fair

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

Exploring the Future: Motor Starters at the 138th Canton Fair 2025 and Industry Trends