How to Choose the Right Electrical Switchgear for Your Industrial Needs

In today's rapidly evolving industrial landscape, the importance of selecting the right electrical switchgear cannot be overstated. Electrical switchgear plays a crucial role in controlling, protecting, and isolating electrical equipment, thereby ensuring operational efficiency and safety. According to a report by Technavio, the global electrical switchgear market is projected to grow by over 7% annually, driven by the increasing demand for renewable energy sources and the modernization of aging infrastructure. This growth underscores the need for industries to not only invest in high-quality electrical switchgear but also to understand the various types available in the market. By making informed decisions tailored to their specific industrial requirements, companies can enhance their operational reliability and significantly mitigate risks associated with electrical failures.

In today's rapidly evolving industrial landscape, the importance of selecting the right electrical switchgear cannot be overstated. Electrical switchgear plays a crucial role in controlling, protecting, and isolating electrical equipment, thereby ensuring operational efficiency and safety. According to a report by Technavio, the global electrical switchgear market is projected to grow by over 7% annually, driven by the increasing demand for renewable energy sources and the modernization of aging infrastructure. This growth underscores the need for industries to not only invest in high-quality electrical switchgear but also to understand the various types available in the market. By making informed decisions tailored to their specific industrial requirements, companies can enhance their operational reliability and significantly mitigate risks associated with electrical failures.

Understanding the Basics of Electrical Switchgear in Industrial Applications

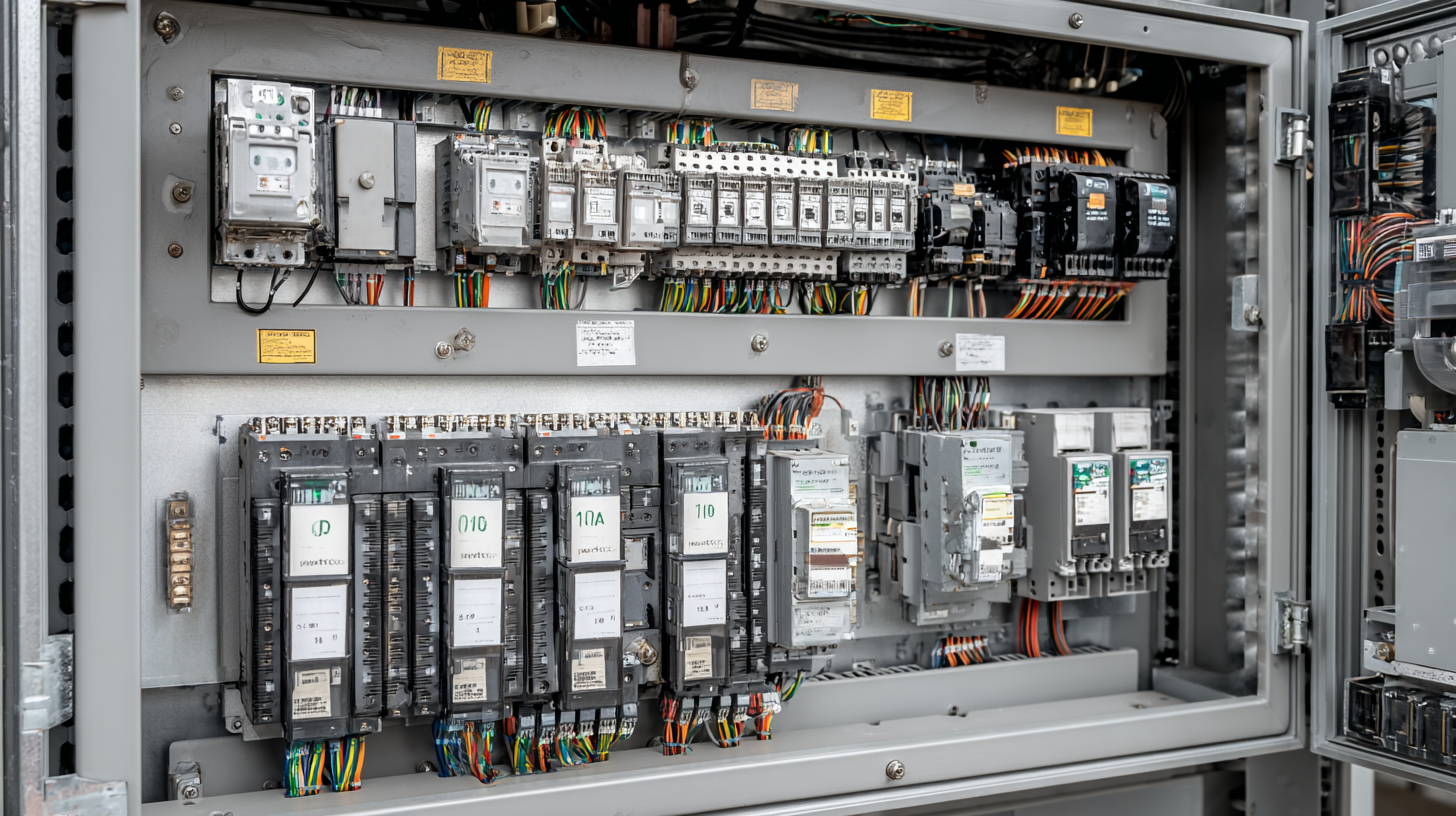

When selecting electrical switchgear for industrial applications, understanding the fundamentals is crucial. Electrical switchgear serves as the backbone of industrial electrical systems, offering protection, control, and isolation of electrical equipment. According to industry reports, the global switchgear market is expected to grow significantly, driven by the increasing demand for reliable and efficient power distribution solutions. This growth highlights the necessity for businesses to invest in high-quality switchgear that meets their specific operational needs.

One of the key factors to consider when choosing switchgear is its modularity and scalability. Modern switchgear systems, such as molded case circuit breakers, are designed to offer flexibility and adaptability, allowing industries to customize their setups based on changing requirements. A report from industry analysts suggests that integrating advanced features such as smart monitoring and maintenance capabilities can enhance operational efficiency and reduce downtime. Moreover, opting for switchgear solutions that incorporate advancements in thermal management can significantly improve performance and longevity, thereby ensuring a reliable power supply for critical industrial processes.

Key Considerations When Selecting Electrical Switchgear for Your Facility

When selecting electrical switchgear for your industrial facility, several key considerations can guide you towards making the right choice.

Power availability has emerged as a primary factor driving site selection decisions, especially for data centers. As industrial facilities often require reliability and flexibility in power management, ensuring that the switchgear can accommodate the available power capacity is crucial.

One of the first things to assess is the operational load requirements of your facility. Consider not only the current demands but also future growth projections. This foresight can help in choosing switchgear that can handle increased loads without needing frequent upgrades.

Another important aspect is the type of switchgear technology. Options vary from traditional air-insulated switchgear to more advanced digital solutions. Digital switchgear can provide enhanced monitoring and diagnostics, offering greater operational insights.

Tips:

- Always collaborate with electrical engineers to analyze the specific requirements of your operations and select switchgear that matches these needs effectively.

- Evaluate the total cost of ownership, including installation, maintenance, and potential upgrades, to ensure long-term benefits outweigh initial expenditures.

Comparing Different Types of Electrical Switchgear: Pros and Cons

When it comes to choosing the best gripping technique in table tennis, players primarily lean towards either the shakehand grip or the penhold grip. The shakehand grip, resembling a traditional handshake, offers a versatile well-rounded style, allowing players to execute a wide array of strokes — from powerful forehands to effective backhands. This grip is favored by many, especially in Western countries, due to its adaptability in both offensive and defensive play. However, it can sometimes limit wrist motion, potentially affecting the quickness of certain shots.

On the other hand, the penhold grip is particularly popular among Asian players, especially in China. This technique allows for remarkable wrist flexibility, leading to quick and precise shots, especially on the forehand side. The penhold grip can be advantageous for aggressive play styles, enabling players to perform rapid spins and slams. However, it may limit reach on the backhand side, requiring players to invest more practice into compensating for this weakness. Each grip offers distinct advantages and disadvantages, ultimately depending on personal preference and playing style.

How to Choose the Right Electrical Switchgear for Your Industrial Needs - Comparing Different Types of Electrical Switchgear: Pros and Cons

| Type of Switchgear | Pros | Cons | Ideal Use Cases |

|---|---|---|---|

| Air-insulated Switchgear (AIS) | Cost-effective, easy maintenance, good performance under normal conditions. | Larger footprint, sensitive to environmental conditions. | Substations, industrial facilities. |

| Gas-insulated Switchgear (GIS) | Compact size, high reliability, lower maintenance costs. | Higher initial cost, complex to install. | Urban areas, space-constrained sites. |

| Hybrid Switchgear | Combines benefits of both AIS and GIS, flexible layout options. | Higher complexity, requires specialized knowledge. | Smart grids, renewable energy applications. |

| Compact Switchgear | Space-saving design, easy installation. | Limited capacity, not suitable for large loads. | Commercial buildings, small industrial setups. |

Safety Standards and Compliance in Electrical Switchgear Selection

When selecting electrical switchgear for industrial applications, safety standards and compliance are of utmost importance. Ensuring that your equipment meets established guidelines, such as those provided by NFPA 70, 70B, and 70E, is critical for maintaining a safe working environment. These standards outline essential practices for electrical maintenance and safety, helping to create a robust compliance framework that protects both personnel and equipment. By adhering to these regulations, industries can minimize risks associated with electrical faults and optimize operational efficiency.

In addition to understanding safety standards, it’s vital to consider the specific needs of your facility when choosing switchgear. Factors such as the type of switchgear—fused or non-fused—and the mounting options like panel or DIN rail—play a significant role in compliance. Furthermore, evaluating the voltage requirements and ensuring compatibility with surge protection devices can enhance safety measures. By carefully navigating these considerations and aligning your choices with regulatory standards, you can ensure that your electrical switchgear not only meets legal requirements but also supports the overall safety and functionality of your industrial operations.

Maintenance and Durability: Ensuring Longevity of Your Electrical Switchgear

Electrical switchgear plays a crucial role in maintaining the reliability and safety of industrial operations. One of the key factors in ensuring the longevity of electrical switchgear is its maintenance and durability. Research by the International Energy Agency (IEA) highlights that regular inspections and maintenance can improve lifespan by up to 30%, drastically reducing the likelihood of unexpected failures. This emphasizes the importance of implementing a proactive maintenance strategy, which includes routine cleaning, testing, and timely replacement of worn components.

Moreover, the durability of switchgear is heavily influenced by the environmental conditions in which it operates. According to a report from the IEEE, switchgear exposed to extreme temperatures, humidity, or corrosive substances can experience a significant decrease in lifespan, often falling below 10 years. By selecting materials designed to withstand specific environmental challenges and adhering to rigorous maintenance schedules, organizations can enhance the performance and reliability of their switchgear systems. Investing in high-quality components and training staff on best maintenance practices will further contribute to the overall durability, ensuring that the switchgear remains operational for years to come.

Related Posts

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications