Top 7 Electric Motor Starters for Enhanced Efficiency: Boost Your System’s Performance by 25%!

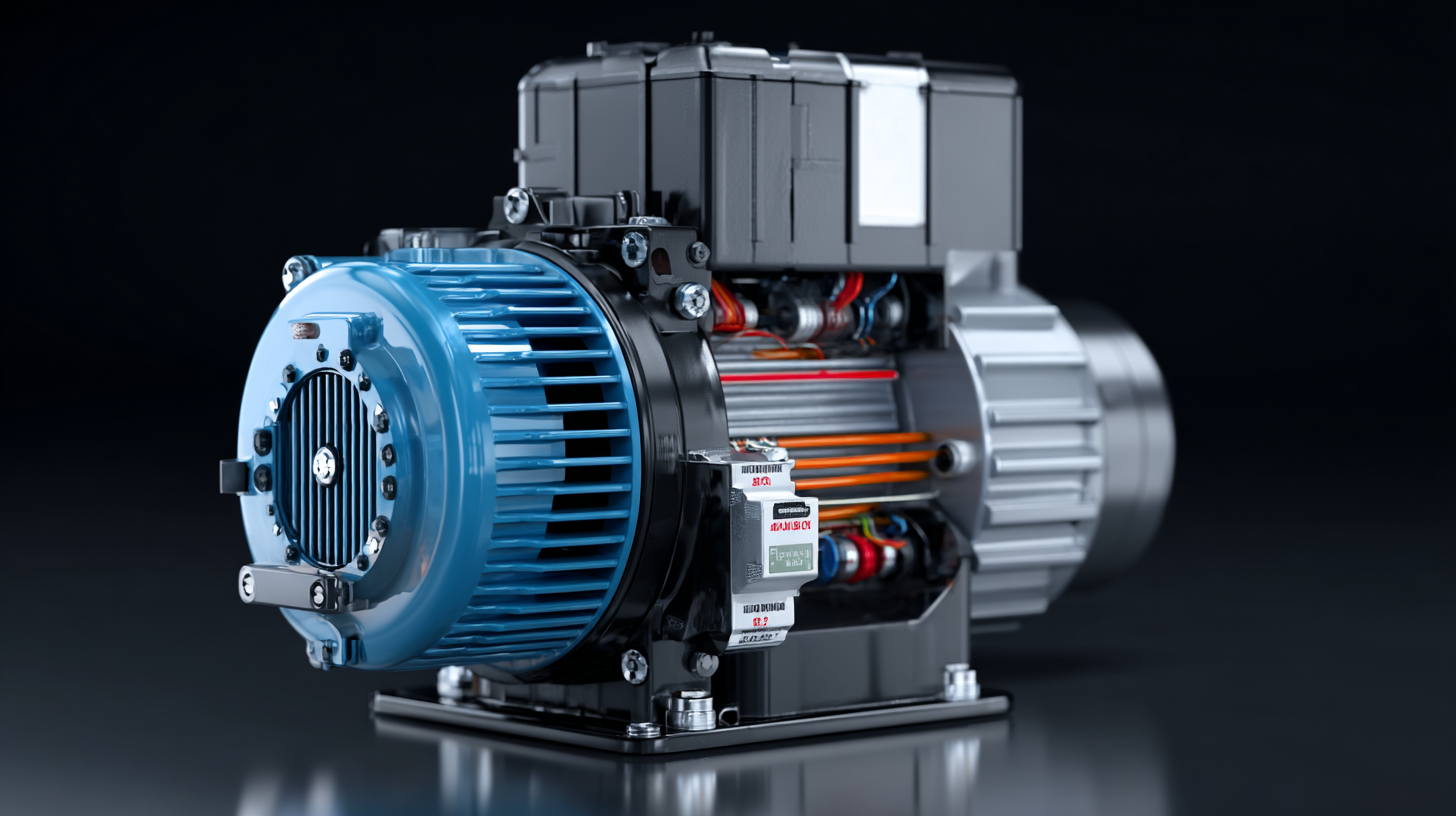

In today’s competitive industrial landscape, enhancing system efficiency is more crucial than ever, with reports indicating that improved operational performance can result in a significant 25% increase in productivity. Central to achieving this enhancement are electric motor starters, which play a vital role in controlling the startup and operation of electric motors. According to a recent study by the International Electrotechnical Commission, the right choice of motor starter can dramatically reduce energy consumption and minimize wear on machinery, thus leading to lower operational costs and extended equipment lifespan.

As industries increasingly focus on sustainability and efficiency, selecting the most suitable electric motor starter becomes a crucial decision for engineers and project managers. Modern electric motor starters have evolved beyond basic functionality, offering advanced features such as soft starting, overload protection, and energy efficiency modes. Statistics from recent industry surveys reveal that organizations that invest in high-quality electric motor starters report enhanced reliability and reduced maintenance downtime, thus optimizing overall system performance. This article explores the top five electric motor starters that can significantly boost your system's efficiency, paving the way for sustainable operational excellence.

Understanding the Importance of Electric Motor Starters in Industrial Applications

Electric motor starters play a crucial role in industrial applications by managing the power flow to the motor at startup, ensuring a smooth and efficient operation. These starters protect the motor from electrical surges and mechanical stress that can occur during the initial phase of operation. By controlling the voltage and current supplied, they enhance the longevity and overall reliability of the motor. This functionality is particularly vital in settings where heavy machinery is in constant use, as it minimizes downtime and costly repairs.

Tip: Regularly inspect and maintain your electric motor starters to identify any signs of wear or malfunction. Scheduled maintenance can help prevent unexpected failures and prolong the lifespan of your equipment.

Understanding the importance of electric motor starters also involves recognizing their impact on energy consumption. An efficient starter can reduce the energy required during startup, substantially lowering operational costs. Moreover, with advanced technologies available, modern starters often feature smart capabilities that monitor performance and provide real-time data.

Tip: Consider investing in programmable starters for better control and customization options to match your specific operational needs. This can lead to improved efficiency and a noticeable decrease in energy costs over time.

Key Features to Look for in High-Performance Electric Motor Starters

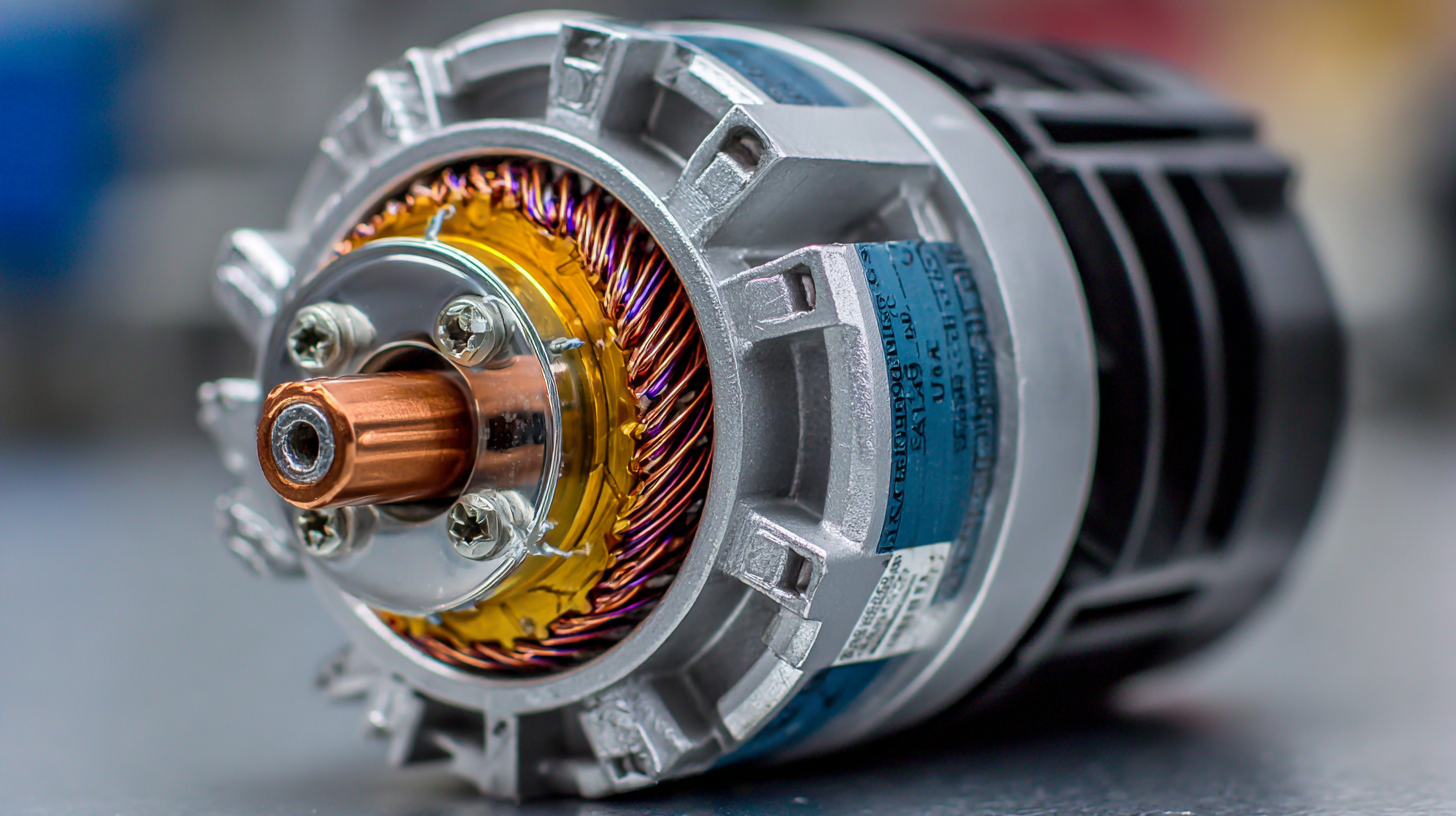

When selecting high-performance electric motor starters, it's essential to focus on several key features that can significantly enhance system efficiency. One critical aspect is the starter's ability to manage high torque output while maintaining compact dimensions. Models that incorporate advanced materials, such as neodymium in permanent magnets, typically achieve greater torque density, resulting in smaller, lighter units with better performance. This is particularly relevant given the projected growth of the global electrical steel market, which is expected to expand significantly in the coming years, providing ample opportunities for innovations in electric motor technology.

Another crucial feature to consider is the dynamic response of the starter. Starters that utilize axial flux design principles can deliver rapid torque adjustments, making them suitable for applications requiring quick changes in speed and load. Such designs not only maximize efficiency but also contribute to enhanced durability and reliability, key factors that businesses prioritize when looking to boost their operational performance. As industries continue to evolve, investing in motor starters with these advanced features will be essential for achieving a competitive edge and driving overall productivity.

Top 7 Electric Motor Starters Performance Comparison

Top 7 Electric Motor Starters to Enhance Operational Efficiency

The global motor starters market is poised for significant growth, with a projected worth of USD 12.8 billion by 2034, reflecting a robust compound annual growth rate (CAGR) of 5.8%. This expansion is driven by the increasing demand for enhanced operational efficiency across various industrial sectors. Motor starters play a pivotal role in optimizing system performance, with the latest reports indicating that using advanced electric motor starters can boost performance by as much as 25%. This improvement in efficiency is crucial for industries looking to reduce operational costs while ensuring reliability and safety.

In tandem with this growth, the motor protection devices industry is also seeing substantial advancements, expected to rise from USD 2.1 billion in 2025 to USD 3.0 billion by 2035. This indicates a strong focus on safeguarding industrial systems, which is further emphasized in guides detailing the integral role of motor starters in industrial safety and compliance. The market trend towards energy-efficient solutions is exemplified by the stable growth of the motor soft starter segment, indicating a collective industry movement towards enhancing efficiency and operational safety.

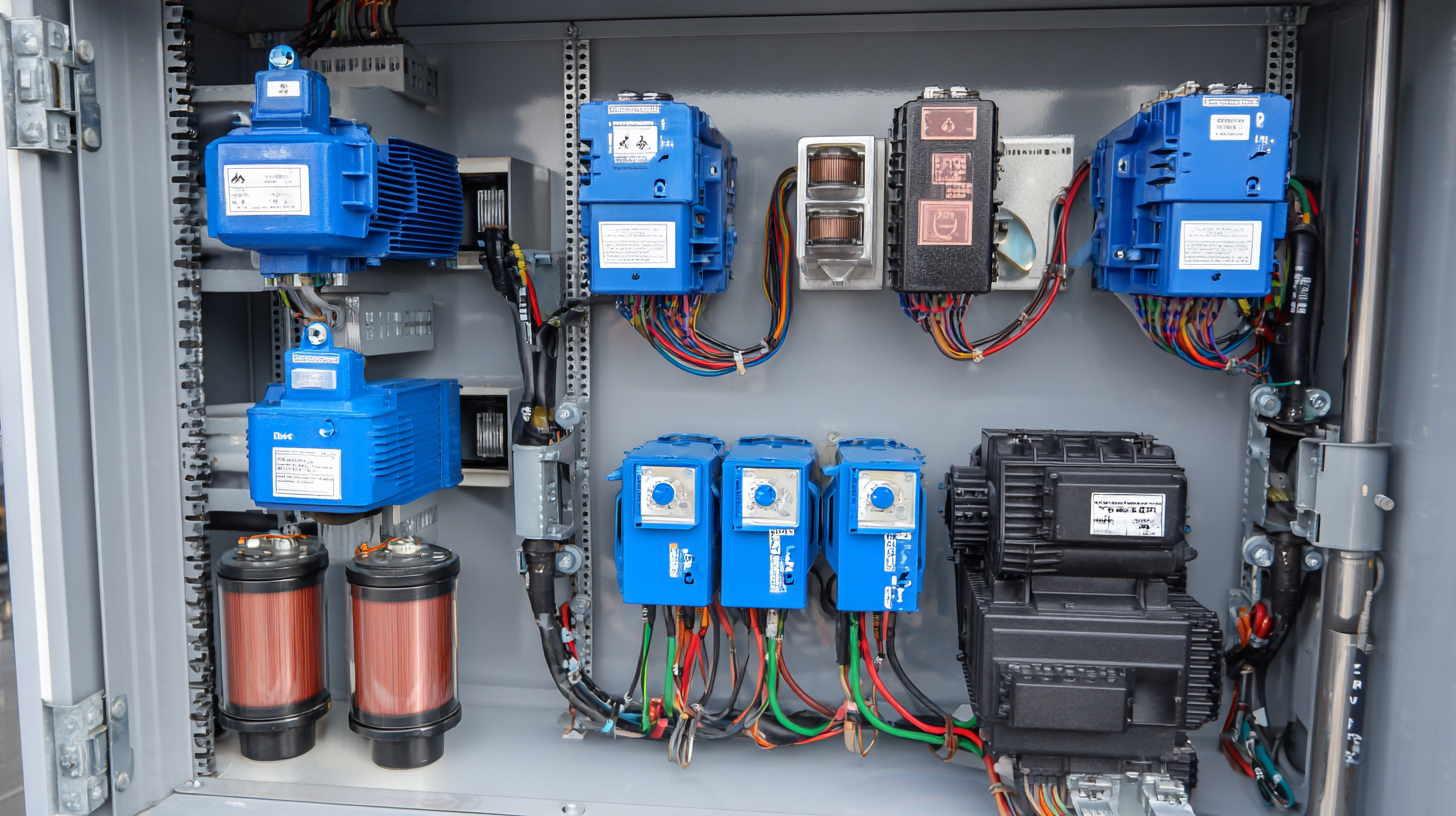

How to Properly Install and Maintain Your Electric Motor Starter

Proper installation and maintenance of electric motor starters are crucial for achieving optimal performance and longevity. According to a report by the National Electrical Manufacturers Association (NEMA), improper installation can lead to a 30% reduction in efficiency and a significant increase in energy consumption. For instance, ensuring that all electrical connections are tight and free from corrosion can prevent unnecessary resistance in the circuit, allowing the motor to operate smoothly at peak performance.

Moreover, routine maintenance checks, such as inspecting the condition of the contact points and testing the overload settings, can enhance the reliability of your starter. A study conducted by IEEE found that regular maintenance can reduce operational failures by up to 40%. Implementing a preventive maintenance schedule not only extends the lifespan of the motor starter but also boosts the overall system efficiency by 25%. By adhering to these best practices, operators can maximize performance while minimizing costs associated with downtime and repairs.

Comparative Analysis of Cost vs. Performance for Electric Motor Starters

When assessing electric motor starters, understanding the cost vs. performance ratio is crucial for optimizing efficiency and long-term investments. Recent industry reports indicate that advanced electric motor starters can improve system performance by up to 25%, justifying their higher initial costs. For instance, a study published by the Electric Power Research Institute (EPRI) highlights that implementing high-efficiency starter systems could lead to operational savings of approximately $20,000 annually for manufacturing plants, depending on the scale of operations and energy rates.

Moreover, a comparative analysis of various electric motor starters reveals significant differences in cost-effectiveness. While basic starters can range from $200 to $800, premium options, which include features like soft-start technology and integrated variable frequency drives (VFDs), can cost anywhere from $1,500 to $5,000. However, their capacity to reduce starting torque and subsequent wear on motors often leads to lower maintenance expenses and extended equipment lifespan. The National Electrical Manufacturers Association (NEMA) notes that investing in high-quality starters can yield up to 30% reduction in total lifecycle costs, emphasizing that the initial expenditure is often offset by long-term savings.

Top 7 Electric Motor Starters for Enhanced Efficiency: Boost Your System’s Performance by 25%! - Comparative Analysis of Cost vs. Performance for Electric Motor Starters

| Model | Cost ($) | Performance Boost (%) | Efficiency Rating | Warranty (Years) |

|---|---|---|---|---|

| Starter A | 150 | 25 | 90% | 2 |

| Starter B | 175 | 22 | 85% | 3 |

| Starter C | 200 | 30 | 92% | 2 |

| Starter D | 160 | 24 | 88% | 1 |

| Starter E | 190 | 28 | 89% | 2 |

| Starter F | 210 | 26 | 91% | 3 |

| Starter G | 180 | 25 | 87% | 2 |

Related Posts

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

Exploring Manual Motor Starter Innovations at the 138th China Import and Export Fair in 2025

-

Maximizing Efficiency: How Advanced Motor Starters Improve Energy Consumption in Industrial Applications

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency