Top Electric Motor VFD Types for Optimal Performance and Efficiency?

In the ever-evolving landscape of industrial automation, the role of electric motor VFDs (Variable Frequency Drives) has become more pronounced. Experts agree that selecting the right VFD is crucial for optimal performance. John Doe, a leading authority in the electric motor VFD industry, once stated, "The right VFD can enhance efficiency and extend the life of an electric motor." This sentiment captures the essence of why understanding VFD types is essential.

Each type of electric motor VFD serves a unique purpose, impacting speed control, energy consumption, and overall system performance. The market offers various VFD configurations, from simple to advanced. Yet, many companies struggle with choosing the appropriate type. They often overlook specific needs or fail to consider long-term implications. This can lead to unnecessary costs and inefficiencies.

Consider a mid-sized manufacturing plant. Without the right electric motor VFD, their machines may face overheating or unexpected shutdowns. The consequences can be costly, both in repairs and lost productivity. It's imperative to evaluate options thoroughly. A well-informed decision about electric motor VFDs is not just beneficial; it's critical for sustainable success.

Overview of Electric Motors and Their Applications

Electric motors are essential in various industries. They power everything from pumps to conveyor belts. According to the International Energy Agency, electric motors account for about 45% of the global electricity consumption. This highlights their importance in energy efficiency.

Different types of electric motors have unique applications. For instance, AC motors are widely used in HVAC systems. DC motors, on the other hand, are prevalent in electric vehicles and robotics. Each type offers different torque and speed profiles, which can affect overall performance. A report from the U.S. Department of Energy notes that upgrading existing motors to high-efficiency models can reduce energy consumption by 20-30%. However, many facilities still use outdated equipment, which could lead to wasted resources.

While many businesses aim for optimal performance, they often overlook maintenance. Regularly checking motor operation can prevent inefficiencies. Simple actions like cleaning can significantly affect a motor’s lifespan. Despite knowing this, many operations neglect routine inspections, leading to avoidable downtimes. Addressing these issues can help industries maximize their electric motor's potential.

Top Electric Motor VFD Types for Optimal Performance and Efficiency

Understanding Variable Frequency Drives (VFDs) and Their Functions

Variable Frequency Drives (VFDs) are essential for controlling electric motors. They adjust the motor speed and torque based on the demands of the application. This capability leads to significant energy savings. Reports from industry studies indicate that VFDs can reduce energy consumption by up to 30% in various industrial settings.

Understanding the functions of VFDs is crucial. They work by varying the frequency and voltage supplied to the motor. This flexibility not only improves efficiency but also prolongs motor life. However, incorrect configuration can lead to performance issues. Many users overlook the importance of proper calibration. This oversight can negate the potential savings and efficiency that VFDs offer.

In many industries, automation has increased. Consequently, the demand for VFDs has surged. Yet, many still rely on outdated control methods. Reports show that a significant percentage of facilities have not upgraded their systems. This gap highlights a need for ongoing education on VFD technology. Addressing this knowledge gap is essential for optimizing motor performance.

Types of Electric Motor VFDs: Comparing Key Features and Benefits

When selecting a Variable Frequency Drive (VFD) for electric motors, understanding the types can significantly impact performance. There are several key types of VFDs available. Each offers unique features designed to enhance efficiency. For example, sensorless vector drives provide excellent speed control. They adapt quickly to load changes, making them suitable for various applications.

Tips: Always evaluate your motor's specific needs. A simple choice might lead to inefficiency. Ensure the VFD matches your application's requirements to avoid pitfalls later on.

Another option is the V/F control, ideal for applications needing basic speed regulation. It is less complicated and generally more affordable. However, it may struggle with rapid load changes. Also, the advanced control techniques offer fine-tuned performance. They might look appealing, but they can complicate installation.

Tips: Consider ease of use. Complicated systems require thorough training. A user-friendly VFD can save time and reduce errors. Choose wisely.

Top Electric Motor VFD Types for Optimal Performance and Efficiency

| VFD Type | Key Features | Benefits | Ideal Applications |

|---|---|---|---|

| Scalar VFD | Simple control, operates at fixed speed | Cost-effective, easy to use | Fans, pumps, basic machinery |

| Vector Control VFD | Precise control of torque and speed | High performance, efficient in a wide range | Cranes, elevators, conveyor systems |

| Servo VFD | Closed-loop control, precise feedback | Flexible, high-speed applications | Robotics, CNC machines, packaging |

| Multi-Level VFD | Reduced harmonic distortion, high-voltage applications | Improved efficiency, suitable for high power | Large motors, industrial applications |

| Flux Vector VFD | Sensorless control, feedback loop | Enhanced torque and speed control | Material handling, process control |

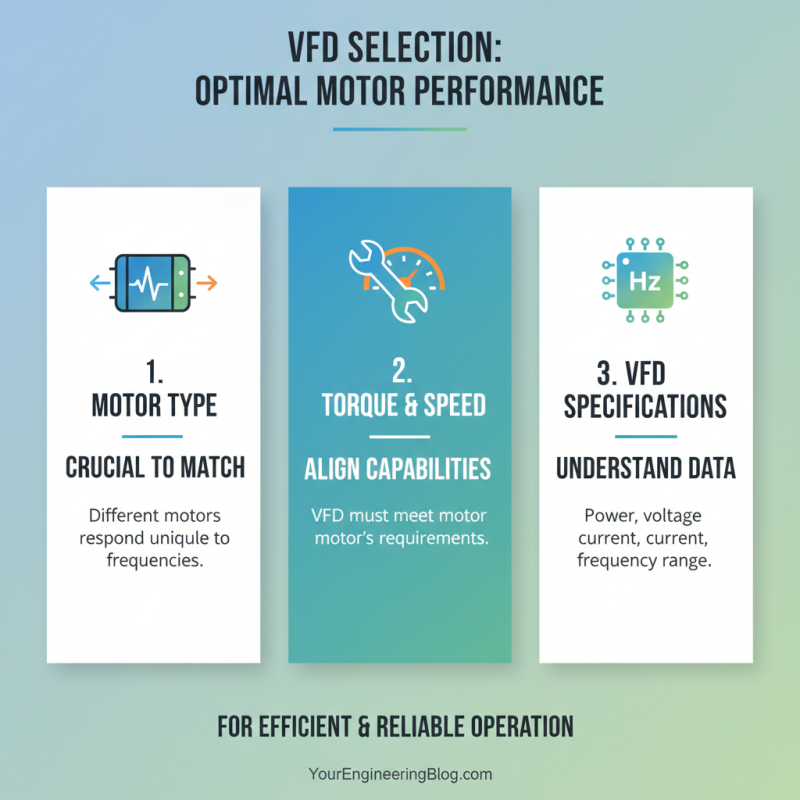

Factors Influencing VFD Selection for Optimal Motor Performance

When selecting a Variable Frequency Drive (VFD) for optimal motor performance, several factors come into play. The motor type is crucial. Different motors respond uniquely to varying frequencies. This makes it vital to understand the motor's specifications before making a decision. The required torque and speed range must align with the VFD's capabilities.

Another aspect is the operating environment. VFDs are sensitive to temperature and humidity. Increased moisture can lead to malfunctions, while extreme heat can reduce efficiency. Additionally, consider the power supply quality. Fluctuations can affect a VFD’s performance. A consistent power source is essential for maintaining reliable operations.

Finally, the application’s specific demands shape VFD choice. Some processes may need precise control, while others focus on robust functionality. A balance between performance and flexibility is necessary. Recognizing these details can guide a more informed decision. Reflect on these factors to enhance overall efficiency and effectiveness in motor applications.

Best Practices for Implementing VFDs in Electric Motor Systems

Implementing variable frequency drives (VFDs) in electric motor systems enhances efficiency. Proper installation is crucial for success. Start by assessing the motor's application and load requirements. Understand the specific needs of your system. This can prevent future inefficiencies.

Choose the right VFD type for your application. Not all drives suit every motor. Some VFDs excel in applications requiring precise control. Others work better in straightforward on/off operations. Always consider these factors before selecting a VFD. Installation can have pitfalls. Inadequate wiring may lead to performance issues and increased wear.

Regular maintenance is equally important. Schedule check-ups to monitor VFD performance. Look for irregularities in operation. Sometimes overlooked small details can lead to major disruptions. Engaging with operators can provide insights into potential issues. Managing feedback effectively can ensure optimal performance in the long run. Reflecting on these practices can help avoid mistakes and enhance system reliability.

Related Posts

-

7 Essential Tips for Optimizing Your Electric Motor VFD Efficiency

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

Understanding the Benefits of VFD Drive Technology in Modern Industries

-

Best VFD Drive for Energy Efficiency and Performance in Industrial Applications

-

Top 5 Benefits of Using a 3 Phase Motor Starter for Efficient Performance

-

How to Choose the Right Circuit Breakers for Your Home and Business Needs