Top 10 Industrial Motors: Key Features and Buying Guide for 2023

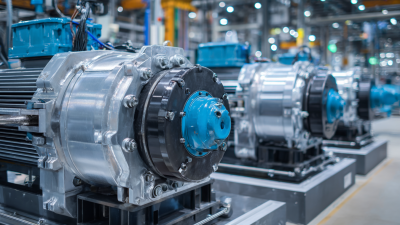

In the ever-evolving landscape of manufacturing and production, industrial motors play a pivotal role in powering machinery and driving efficiency. As businesses strive to optimize their operations and increase productivity, the selection of the right industrial motors becomes crucial. With a plethora of options available, it’s essential to understand the key features that distinguish one motor from another and to navigate the intricacies of selecting the ideal model for specific applications.

This guide delves into the top 10 industrial motors for 2023, outlining the fundamental characteristics, performance metrics, and technological advancements that define each type. Whether you are in the market for reliable AC motors, efficient DC motors, or advanced servo systems, knowing the essential specifications and operational capabilities will empower you to make informed decisions that align with your operational needs. Join us as we explore the vital aspects of industrial motors, enabling you to harness the power of these essential components effectively.

Key Considerations When Choosing Industrial Motors for Your Needs

When selecting industrial motors, understanding key considerations is crucial for ensuring optimal performance and efficiency within your specific application. First and foremost, the type of motor is fundamental to your decision-making process. Induction motors are commonly chosen for their reliability in various environments, while servo motors offer precision control for applications requiring high accuracy. Additionally, the environment where the motor will operate plays a significant role; factors such as temperature, humidity, and exposure to contaminants can influence the choice of motor type and protective features.

Another essential consideration is the motor's power rating and torque requirements. It’s important to accurately assess the demands of your application to avoid underperformance or overloading the motor. Similarly, evaluating the speed range is imperative, as different processes may require varying RPM (revolutions per minute). Furthermore, energy efficiency should not be overlooked, especially with growing requirements for sustainability. Selecting a motor with an appropriate efficiency rating can lead to significant cost savings in the long run, as well as compliance with energy regulations. These factors collaboratively impact not only the functionality but also the overall operational cost of the equipment in which the motor will be integrated.

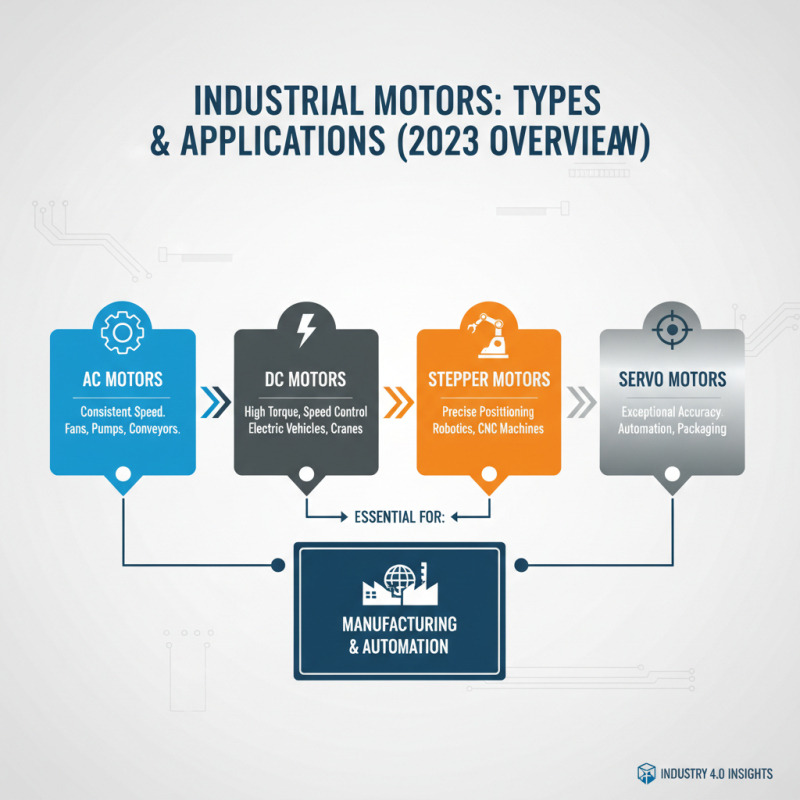

Overview of the Types of Industrial Motors Available in 2023

Industrial motors are essential components in a wide array of applications, ranging from manufacturing to automation. In 2023, the market offers several types of industrial motors, each designed to meet specific operational demands and application requirements. The most common types include AC motors, which are ideal for consistent speed applications, and DC motors, known for their high torque and speed control capabilities. Additionally, stepper motors serve precise positioning needs in robotics and CNC machinery, while servo motors provide exceptional accuracy for motion control in dynamic environments.

Furthermore, specialized motors such as variable frequency drives (VFDs) allow for adjustable speed and efficiency, making them favorable for applications with fluctuating loads. On the other hand, brushless motors, celebrated for their durability and reduced maintenance needs, are increasingly used in advanced automation systems. Each type of motor comes with unique features such as thermal protection, torque ratings, and efficiency class, which are vital considerations for buyers. Understanding the distinctions and advantages of these various industrial motors will assist in selecting the right option for specific operational needs in today’s industrial landscape.

Essential Features of High-Quality Industrial Motors to Look For

When selecting industrial motors, it's crucial to understand the essential features that define high-quality options for efficient operation. A well-constructed industrial motor should have a robust design that can withstand harsh environments and heavy workloads. Look for models with high durability ratings, which indicate the ability to operate under prolonged use without failures. Additionally, energy efficiency is a vital criterion; motors that meet high efficiency standards can significantly reduce operational costs over time.

Consider the motor's power rating and torque capabilities, as these will determine its suitability for specific applications. A motor should provide consistent performance under varying load conditions, which is particularly important in industrial settings. Moreover, features like thermal protection mechanisms and built-in overload sensors can prevent motor damage and enhance safety.

Tips: Always check for compatibility with your existing systems and the motor's ease of installation. Investing in a motor that offers smart technology integration, such as IoT compatibility, can lead to improved monitoring and maintenance, ultimately increasing productivity. Lastly, consider whether the motor comes with a solid warranty, which can offer peace of mind regarding its longevity and reliability.

Top 10 Recommended Industrial Motors and Their Unique Benefits

When selecting the right industrial motor for your applications in 2023, it's essential to consider the unique benefits offered by various models. Industrial motors are pivotal in driving machinery, with efficiency being a primary factor. According to a recent report from the International Electrotechnical Commission (IEC), approximately 70% of industrial electrical energy consumption is attributed to motor systems. Opting for high-efficiency motors not only enhances performance but also significantly reduces operational costs over time.

Among the top recommended industrial motors, features such as high torque capabilities, variable speed control, and robust designs are paramount. For instance, motors designed with advanced cooling systems can operate effectively in high-temperature environments, while those with integrated smart technology can optimize performance and reduce energy waste. These enhancements not only improve productivity but also extend the lifespan of the motor, making them a cost-effective solution in the long run.

**Tips:** When evaluating industrial motors, always assess the total cost of ownership, which includes initial purchase price, energy consumption, and maintenance costs. Additionally, consider the motor's compatibility with existing systems to minimize integration challenges. Lastly, take note of the availability of after-sales support, as this can significantly impact the operational efficiency of your equipment.

Top 10 Industrial Motors: Key Features and Buying Guide for 2023

| Motor Type | Power Rating (HP) | Voltage (V) | Efficiency Class | Unique Features |

|---|---|---|---|---|

| AC Induction Motor | 1 - 300 | 230/460 | IE2 | Robust design, low maintenance |

| DC Motor | 0.5 - 200 | 12/24/48 | N/A | High torque, speed control |

| Servo Motor | 0.1 - 50 | 230 | IE3 | Precision control, high responsiveness |

| Stepper Motor | 0.1 - 100 | 12/24 | N/A | Open-loop control, easy to integrate |

| Synchronous Motor | 5 - 1000 | 400 - 690 | IE4 | High efficiency, constant speed |

| Gear Motor | 0.5 - 200 | 220/380 | IE2 | Torque multiplication, compact design |

| Universal Motor | 0.1 - 5 | 120/240 | N/A | High speed, low cost |

| Permanent Magnet Motor | 1 - 500 | 230 | IE3 | Compact, high efficiency, low heat |

| Wound Rotor Motor | 5 - 3000 | 400 | IE2 | Slip control, high starting torque |

Buying Guide: Factors to Assess Before Purchasing an Industrial Motor

When considering the purchase of an industrial motor, several critical factors must be evaluated to ensure the right choice for your specific application. First and foremost, assess the motor's power requirements. Different processes demand varying power levels, so identifying the appropriate voltage and horsepower is essential. Additionally, understanding the motor's torque output is vital, particularly for applications that require high starting torque or precise speed control.

Another key aspect to consider is the motor's efficiency rating. An efficient motor not only lowers operational costs but also contributes to sustainability efforts by reducing energy consumption. Look for motors with high efficiency ratings and consider the impact of variable frequency drives (VFDs) that can further enhance performance and energy savings.

Furthermore, evaluate the environmental conditions where the motor will operate, such as temperature, exposure to dust or moisture, and potential vibration. Choosing a motor designed to withstand these conditions will ensure optimal performance and longevity, reducing maintenance and replacement costs in the long run.

Related Posts

-

Understanding the Role of Industrial Electric Motors in Modern Automation Systems

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs

-

2025 Top 5 Motor Soft Starter Options for Efficient Energy Management

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

What are Electrical Breakers and Their Role in Electrical Safety Standards