Top 10 Motors and Controls: Best Technologies for Optimal Performance

In today's fast-evolving industrial landscape, the significance of motors and controls has reached unprecedented levels. According to a recent report by the Global Electric Motor Market, the industry is projected to grow at a compound annual growth rate (CAGR) of 6.2%, reaching an estimated value of over $160 billion by 2027. This growth is driven by increasing demand for energy-efficient solutions and advancements in automation technologies across various sectors including manufacturing, automotive, and renewable energy. As organizations seek to enhance productivity and reduce operational costs, selecting the best technologies for motors and controls becomes critical.

Furthermore, the integration of smart technologies into motors and controls is reshaping operational efficiencies. The World Economic Forum emphasizes that digitally-enabled motors can improve energy efficiency by up to 30%. With the growing emphasis on sustainability and reduced carbon footprints, these technologies are not just improving performance but also contributing to a greener future. As businesses navigate through these changes, understanding and adapting to the latest motor and control technologies will be pivotal for maintaining competitive advantage in the marketplace. This article aims to explore the top ten motors and controls that stand out in providing optimal performance and efficiency, enabling industries to thrive in this dynamic environment.

Top 10 Motors for Enhanced Energy Efficiency in Industrial Applications

In today's fast-paced industrial landscape, enhancing energy efficiency is more crucial than ever. The top motors designed for industrial applications not only deliver superior performance but also significantly reduce energy consumption. With the integration of advanced technologies, these motors optimize operation while lowering costs and minimizing environmental impact. Selecting the right motor can result in remarkable energy savings and improve overall operational efficiency.

Tips for enhancing energy efficiency include regular maintenance checks to ensure all components are functioning optimally. Over time, wear and tear can lead to inefficiencies. Additionally, consider implementing variable frequency drives (VFDs) to better control motor speed and reduce energy usage based on actual demand, rather than running at full capacity all the time. Investing in smart motors with built-in monitoring systems can provide real-time feedback, enabling proactive decisions to maintain energy efficiency.

When integrating new technologies, training your team on proper usage and maintenance practices is essential. Empowering workers to understand the benefits of energy-efficient motors and how to optimize them can lead to a culture of sustainability within your organization. By focusing on these strategies, businesses can not only achieve enhanced energy efficiency but also foster a more responsible and eco-friendly industrial operation.

Advanced Control Technologies Driving Precision in Automation Systems

Advanced control technologies are at the forefront of enhancing precision in automation systems, making them indispensable in various industrial applications. These technologies enable precise control of motors, which is vital for achieving optimal performance in production lines and robotic systems. By integrating advanced sensors and smart algorithms, manufacturers can ensure real-time feedback and enhance the responsiveness of their automation setups. This not only improves efficiency but also significantly reduces operational downtime and maintenance costs.

Tips: To leverage the benefits of advanced control technologies, begin by conducting a thorough assessment of your current automation system. Identify areas where smart sensors and control algorithms can be integrated for better performance. Implementing a phased approach can also help in gradually refining your processes without disrupting ongoing operations.

Another key aspect is the data feedback loop. Utilizing analytics tools that process performance data can help you make informed decisions and adjustments to enhance precision. Regularly reviewing this data will allow for continual improvements, ensuring that your automation systems remain agile and responsive to changing demands in production.

Top 10 Motors and Controls: Best Technologies for Optimal Performance

| Technology | Type | Efficiency (%) | Features | Applications |

|---|---|---|---|---|

| Servo Motor | DC | 90 | High precision, feedback control | Robotics, CNC machines |

| Stepper Motor | Hybrid | 85 | Discrete steps, low cost | 3D printers, automation systems |

| Induction Motor | AC | 92 | Durable, low maintenance | Blowers, pumps |

| Brushless DC Motor | DC | 95 | High efficiency, reduced noise | Electric vehicles, HVAC systems |

| Variable Frequency Drive | Control System | 98 | Speed control, energy savings | Fans, compressors |

| Programmable Logic Controller | Control System | N/A | Customizable, robust | Manufacturing lines |

| Soft Starter | Control Device | N/A | Reduced inrush current | Heavy machinery |

| Integrated Motion Control | Control System | N/A | Seamless communication | Complex automation |

| Human-Machine Interface | UI System | N/A | User friendly, customizable | Control panels |

| Motion Control Software | Software | N/A | Advanced algorithms, data analysis | Robotics, manufacturing |

Key Metrics for Evaluating Motor Performance and Efficiency Ratings

When evaluating motor performance and efficiency ratings, certain key metrics come into play that can provide insights into their operational effectiveness. One of the primary measures is the efficiency rating, typically expressed as a percentage. This rating indicates how well the motor converts electrical energy into mechanical energy. A higher efficiency rating generally means lower energy losses in the form of heat, ultimately leading to reduced operating costs and enhanced sustainability. Understanding the efficiency class of a motor is crucial for selecting the right technology for specific applications.

Another important metric is the power factor, which describes the relationship between the real power used by the motor and the apparent power flowing in the circuit. A power factor closer to one signifies better performance; motors with higher power factors can help maximize the energy usage in a system. Additionally, torque characteristics, including starting torque and running torque, are vital for evaluating how well a motor can perform under various load conditions. Analyzing these metrics collectively allows for a comprehensive assessment of motor performance, ensuring that the chosen technology meets both efficiency and operational requirements effectively.

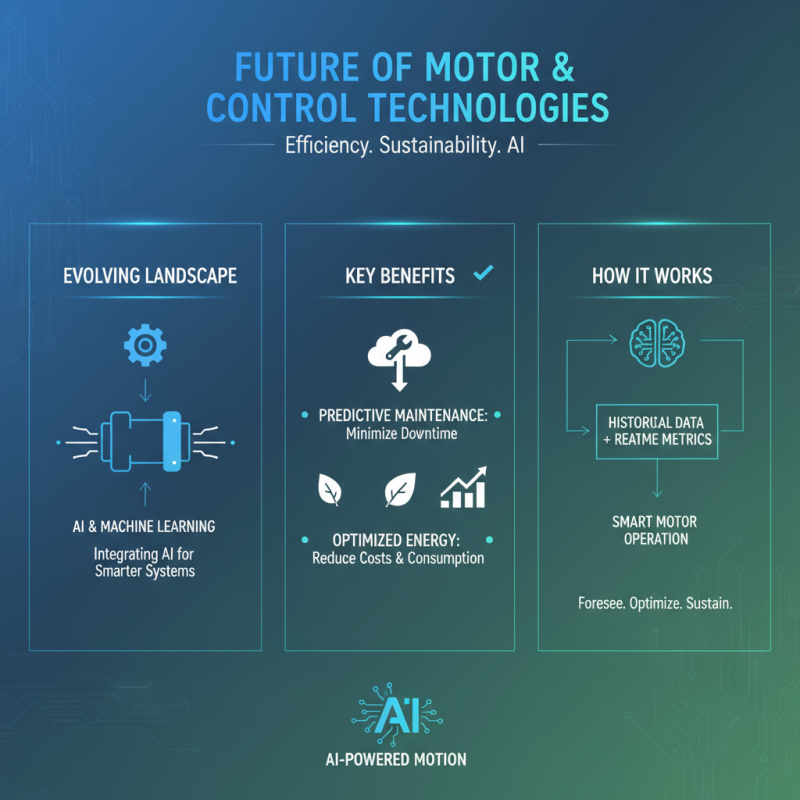

Emerging Trends in Motor and Control Technologies for Future Applications

The landscape of motor and control technologies is evolving rapidly, driven by the need for greater efficiency and sustainability in various applications. One of the emerging trends is the integration of artificial intelligence (AI) and machine learning into control systems. These advanced algorithms enable predictive maintenance, allowing operators to foresee potential failures and thus minimize downtime. By analyzing historical data and real-time performance metrics, AI-driven motors can adapt their operations, optimizing energy consumption and reducing operational costs.

Another significant trend is the development of smart motors that communicate seamlessly with other components within a system, forming an interconnected ecosystem. This new level of connectivity enhances the capabilities of automation, allowing for more sophisticated control strategies and better responsiveness to changing conditions. These smart motors can leverage IoT technologies to gather data from their environment and make autonomous decisions, leading to improved operational efficiencies and enabling more complex applications in industries such as manufacturing, transportation, and renewable energy.

Moreover, sustainability is a key focus, with ongoing research into materials and designs that reduce environmental impact. Innovations such as energy-efficient designs and the use of recyclable materials are becoming critical considerations in the development of future motor technologies. As industries strive for greener solutions, these advancements not only promise better performance but also align with global initiatives to reduce carbon footprints, making motor and control technologies a vital component of future sustainable practices.

Integrating Smart Technologies into Motors for Improved Operational Insights

The integration of smart technologies into motors marks a significant advancement in the realm of industrial performance and operational efficiency. By incorporating sensors and connectivity features, modern motors can now collect real-time data on their performance and environment. This data includes temperature, vibration, and operational load, which contribute to a comprehensive understanding of a motor's health and efficiency. With this information, operators can identify potential issues before they lead to failure, ultimately reducing downtime and maintenance costs.

Moreover, the implementation of advanced analytics and machine learning algorithms enhances the operational insights derived from these smart motors. By analyzing patterns and trends in the collected data, businesses can optimize motor operations for energy consumption and performance output. This not only boosts productivity but also supports sustainability efforts by minimizing waste and energy usage. As industries strive for smarter and more efficient solutions, the integration of these technologies into motors is proving to be a pivotal step towards achieving optimal performance and reliability in today's competitive landscape.

Related Posts

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

2025 Top 5 Motor Soft Starter Options for Efficient Energy Management

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters

-

How to Choose the Right Circuit Breakers for Your Home and Business Needs

-

Exploring Electric Motor Controller Innovations at the 2025 China 138th Canton Fair

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications