How to Understand Motor Control Center Functionality in 2026?

In 2026, understanding the functionality of motor control centers (MCCs) is crucial. As industrial automation grows, the MCC's role becomes vital. Reports show that the global market for motor control centers is expected to reach $4 billion by 2026, reflecting a 7% growth rate. This highlights the increasing reliance on these systems in various industries.

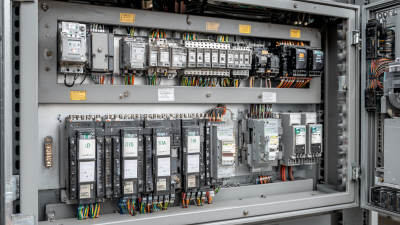

Motor control centers integrate multiple functions for efficient operation. They house circuit breakers, motor starters, and protective devices. However, challenges persist. Many facilities still rely on outdated systems. Their complexities can lead to inefficiencies. As innovation advances, companies must evaluate their current MCCs critically.

Today's operators face a steep learning curve. With technologies evolving rapidly, comprehensive understanding is essential. The evolving nature of the MCC means constant updates to training and operational protocols. This shift necessitates an adaptable workforce that can keep pace with changes. Exploring these trends ensures that organizations maximize performance while minimizing downtime.

Overview of Motor Control Centers and Their Importance

Motor control centers (MCCs) play a critical role in industrial automation. They manage the distribution of electrical power to various motor-driven equipment. In 2026, advanced MCCs will likely focus on efficiency and real-time performance monitoring. A recent report indicates that the global MCC market is projected to reach $12 billion by 2026, driven by the growing demand for automation in manufacturing sectors.

The functionality of motor control centers extends beyond just controlling motors. They provide essential safety features. For instance, integrated overload relays and short circuit protection are standard. However, many facilities still rely on outdated systems. This reliance can lead to safety risks and decreased productivity. Research shows that up to 30% of industrial failures are due to electrical issues.

Moreover, the integration of IoT with MCCs will redefine their importance. Real-time data analytics can enhance decision-making. These improvements can lead to a 20% reduction in energy consumption. Yet, not all organizations are prepared for this shift. Many face challenges in adopting new technologies, risking obsolescence. Incomplete system upgrades may hinder performance. Addressing these gaps will be essential for leveraging the full potential of motor control centers in the coming years.

How to Understand Motor Control Center Functionality in 2026? - Overview of Motor Control Centers and Their Importance

| Dimension | Description | Importance |

|---|---|---|

| Control Components | Includes relays, contactors, circuit breakers, and overload protectors. | Essential for protecting and managing motor operations, preventing failures. |

| Power Distribution | Facilitates efficient distribution of electrical power to motors. | Critical for minimizing energy losses and ensuring operational efficiency. |

| Communication Protocols | Integration of Ethernet, Modbus, and other communication standards. | Facilitates advanced monitoring and control in smart manufacturing systems. |

| Safety Features | Incorporation of safety relays and emergency stop functions. | Vital for ensuring worker safety and compliance with regulations. |

| Customization | Ability to tailor configurations to specific application needs. | Enhances reliability and performance in various industrial environments. |

Key Components and Technologies in Modern Motor Control Centers

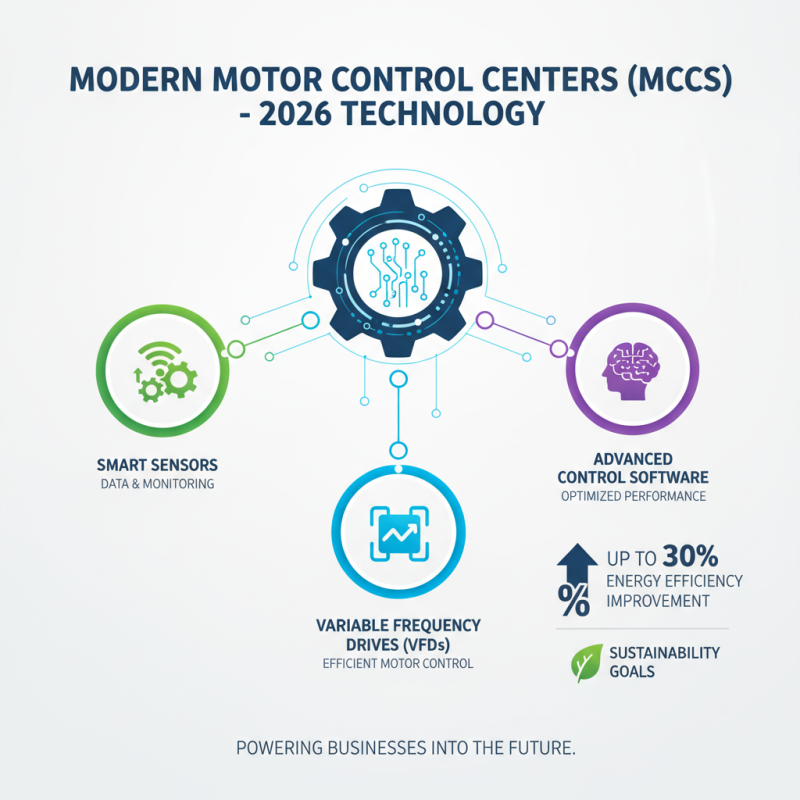

In modern motor control centers (MCCs), technology plays a crucial role. MCCs house various components that manage electrical motors efficiently. In 2026, these components include smart sensors, variable frequency drives, and advanced control software. Reports indicate that smart MCCs can improve energy efficiency by up to 30%. Such advancements are essential for businesses aiming for sustainability.

A significant aspect of MCC functionality is real-time monitoring. Sensors provide data on motor performance. This data assists in predictive maintenance, which can reduce downtime by 25%. However, many organizations still struggle with implementing these technologies effectively. Training staff to use new systems is often overlooked.

**Tips:** Regular training sessions can enhance skills. Ensure your team is aware of updates in technology. Adaptation is key to maintaining operational efficiency.

Communication between MCC components is also critical. Cloud technology allows for remote access to information. This practice enhances decision-making. Yet, data security remains a concern. Companies often fail to address this risk, leaving them vulnerable to threats. Maintaining robust security measures is vital for protecting sensitive information.

Functions and Operations of Motor Control Centers in 2026

In 2026, motor control centers (MCCs) are pivotal in industrial automation. These systems manage electrical motors to improve efficiency and safety in various processes. According to industry reports, the adoption of advanced MCCs has grown by over 30% since 2022. This shift reflects increasing demand for optimized machine performance and energy savings.

MCCs today offer features like remote monitoring, fault diagnostics, and load management. These functions ensure consistent performance and rapid troubleshooting. Some data suggests that smart MCCs can reduce operational costs by up to 15%.

Yet, integrating these advanced systems comes with challenges. Industries report concerns about compatibility with legacy equipment and the steep learning curve for technicians.

Moreover, high initial investment costs can deter some manufacturers. While the long-term benefits are clear, short-term financial strain may lead to hesitation. As industries navigate these choices, the balance between innovation and prudence will become crucial. Understanding the full capabilities of MCCs involves recognizing both their potential and their limitations.

Trends and Innovations Shaping the Future of Motor Control Centers

The evolving functionality of motor control centers (MCCs) is crucial for industries adapting to new technologies. Recent reports indicate that the global MCC market is projected to grow significantly, reaching approximately $5 billion by 2026. This growth hinges on innovations like smart MCCs, which integrate IoT capabilities. These systems enable remote operation and real-time monitoring, transforming operations and maintenance protocols.

As industries pursue automation, energy efficiency becomes paramount. Innovative designs focus on reducing energy consumption. Studies show that modern MCCs can lower energy costs by up to 30%. This significant reduction is linked to advanced control systems and predictive maintenance strategies. However, the shift towards smart technology presents challenges. Many facilities struggle to update legacy systems, leading to increased operational risks.

Data security also poses a concern as more devices get connected. Cybersecurity measures must adapt to protect sensitive information. While the advantages are clear, the transition requires careful planning. Companies must consider investing in training and resources to ensure effective implementation. Balancing innovation with operational stability is essential for success in this dynamic landscape.

Challenges and Solutions in Motor Control Center Implementation

The implementation of motor control centers (MCCs) faces many challenges in 2026. Complexity is rising as technology advances. Organizations struggle with integrating smart devices into their systems. According to a recent report by the International Energy Agency, 75% of manufacturing facilities report difficulties in adopting these new technologies. This poses significant obstacles to upgrading existing MCCs.

Training is another critical issue. A survey found that only 60% of technicians feel adequately trained to manage advanced MCCs. This gap in knowledge can lead to increased downtime and maintenance costs. The lack of effective training resources remains a barrier for many companies. Additionally, safety standards are becoming more rigorous, complicating compliance efforts.

Finally, cost management is a persistent concern. The initial investment for advanced MCC systems can be high. However, the potential long-term savings justify the expense. The challenge lies in balancing immediate costs with future benefits. Companies often find themselves torn between upgrading and maintaining legacy systems. In this dynamic landscape, confronting these challenges head-on is essential for success.

Challenges and Solutions in Motor Control Center Implementation (2026)

Related Posts

-

2025 Top 5 Motor Soft Starter Options for Efficient Energy Management

-

Top Motor and Control Solutions for Enhanced Efficiency and Performance

-

How to Choose the Right 3 Phase Motor Starter for Optimal Performance and Efficiency

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs

-

What is Electrical Switchgear and How Does it Work?

-

Understanding Motor Control Centers and Their Importance in Industry?