Essential Tips for Understanding Motor Control Centers?

Understanding motor control centers is crucial for anyone in the electrical and automation fields. These assemblies play a key role in managing machinery and equipment. A well-functioning motor control center ensures efficiency and safety. A typical motor control center houses multiple components, such as circuit breakers, contactors, and overload relays.

These centers are more than just metal boxes. They are the brains behind operational success in various industries. Breakdowns can lead to costly downtime. Proper maintenance is essential, yet often overlooked. Many operators may not fully grasp the importance of a motor control center's design and layout. A poorly designed setup can cause confusion and mistakes during operation.

Optimizing a motor control center requires both knowledge and attention to detail. Factors like cable sizing and component placement significantly impact overall performance. There are times when unexpected failures happen, revealing design flaws. Engaging with experienced professionals can help avoid these pitfalls. It’s essential to constantly reflect on and improve motor control center operations for better reliability.

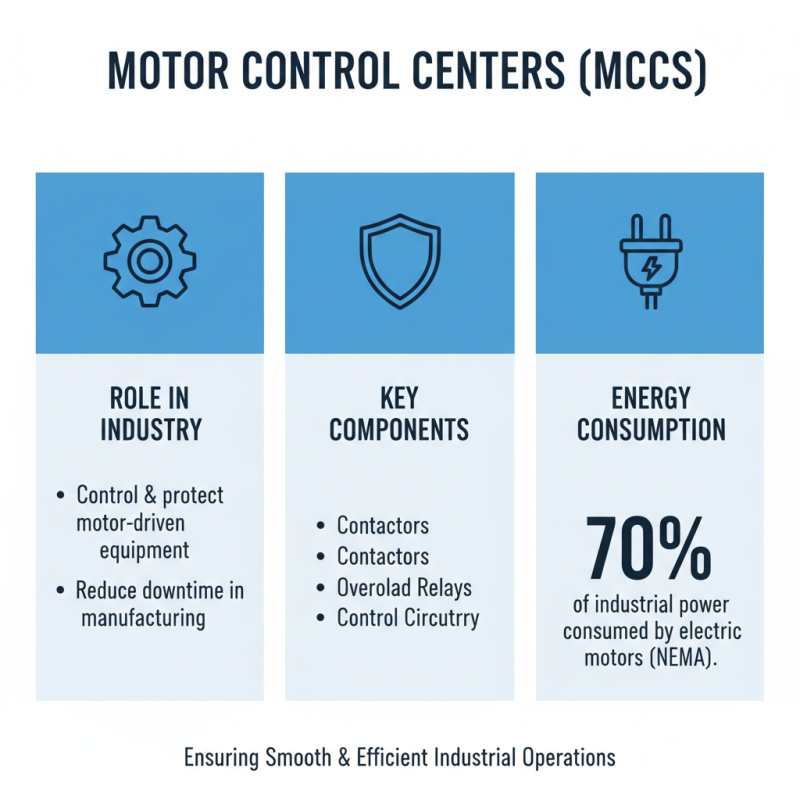

Definition and Purpose of Motor Control Centers in Industrial Applications

Motor Control Centers (MCCs) play a critical role in industrial applications. They are designed to control and protect motor-driven equipment. MCCs house contactors, overload relays, and control circuitry. These components work together to ensure smooth operation. In manufacturing facilities, MCCs can reduce downtime significantly. According to the National Electrical Manufacturers Association, about 70% of industrial power is consumed by electric motors.

MCCs enhance efficiency while ensuring safety. They allow for easy maintenance and monitoring. This can save time during repairs, limiting production interruptions. Data from the Industrial Manufacturing Report indicates that improper motor control can lead to a 30% increase in operational costs. Thus, understanding the purpose of MCCs is crucial. They streamline processes and maintain safety protocols. Still, some industries struggle with outdated systems. These can lead to inefficient energy use. Regular assessments are essential for keeping MCCs updated and effective.

The design of an MCC can impact overall performance. Factors like layout and component selection are important. There is no one-size-fits-all solution. Each application may require a unique approach. Industry experts suggest regular trainings for operators to maximize the use of MCCs. Maintenance reports often highlight the need for improved knowledge among staff. Continued education can bridge this gap and enhance operational efficiency.

Key Components and Design Considerations for Effective MCC Systems

Motor Control Centers (MCC) are vital in industrial applications. They aggregate various electrical components, responsible for controlling and protecting motors. Key components include circuit breakers, contactors, and overload relays. Each part plays a specific role, ensuring the system operates efficiently. Design considerations should not be overlooked. The layout of components affects ease of maintenance.

Proper cooling and ventilation are crucial ideas. Without them, heat buildup can cause failures. It's essential to ensure that the design allows for adequate airflow. Safety is another critical aspect. Emergency stops and safety interlocks must be properly integrated. However, achieving a balance between functionality and safety can be challenging.

Additionally, standardizing components can simplify maintenance but may reduce flexibility. This is a dilemma that engineers often face. They must consider the specific needs of the application. Importantly, design choices should be revisited regularly. Technological advancements can render some designs outdated. Continuous improvement is key to optimizing MCC systems.

Industry Standards and Compliance for Motor Control Centers

Motor control centers (MCCs) play a crucial role in industrial settings. Understanding the industry standards surrounding them is essential for safety and efficiency. Various codes and regulations govern the design and operation of MCCs. Familiarity with these standards ensures compliance and promotes reliable functionality.

Compliance isn't just about following rules. It often requires critical evaluation of existing systems. Many facilities may overlook updates, leading to potential risks. Regular audits and assessments can help identify gaps. Ensuring all components meet the current regulations is vital. Documenting any non-conformities is important for future reference.

Workers should be trained on the implications of these standards. Knowledge gaps can arise, especially with changes in technology. Continuing education can bridge these gaps. It’s not unusual to find outdated practices still in use. Companies must encourage a culture of safety and compliance. Reflecting on past decisions often reveals areas for improvement. Adapting to new standards is not just necessary—it's a responsibility.

Trends in Motor Control Technology and Their Impact on Efficiency

Motor control technology is rapidly evolving. Understanding recent trends can greatly impact operational efficiency. New developments in these technologies lead to smarter, more responsive systems. For instance, digital controllers often provide real-time monitoring. This feature helps identify issues before they escalate. Efficiency is not just about speed. It's about precision and reliability.

Recent trends also highlight the importance of integration. Motor control centers are increasingly designed to work seamlessly with other systems. This interconnectedness reduces downtime and increases productivity. However, relying solely on technology can create vulnerabilities. Employees must remain informed and trained. Automation won’t eliminate the need for human expertise.

Efficiency requires continuous evaluation. Every new piece of technology needs reflection. Sometimes, integrating too many systems can complicate operations. Simplifying processes is key to maintaining effectiveness. In the end, the goal should be greater efficiency, but it’s important to recognize the learning curve too. Balancing innovation with practical experience is essential.

Trends in Motor Control Technology and Their Impact on Efficiency

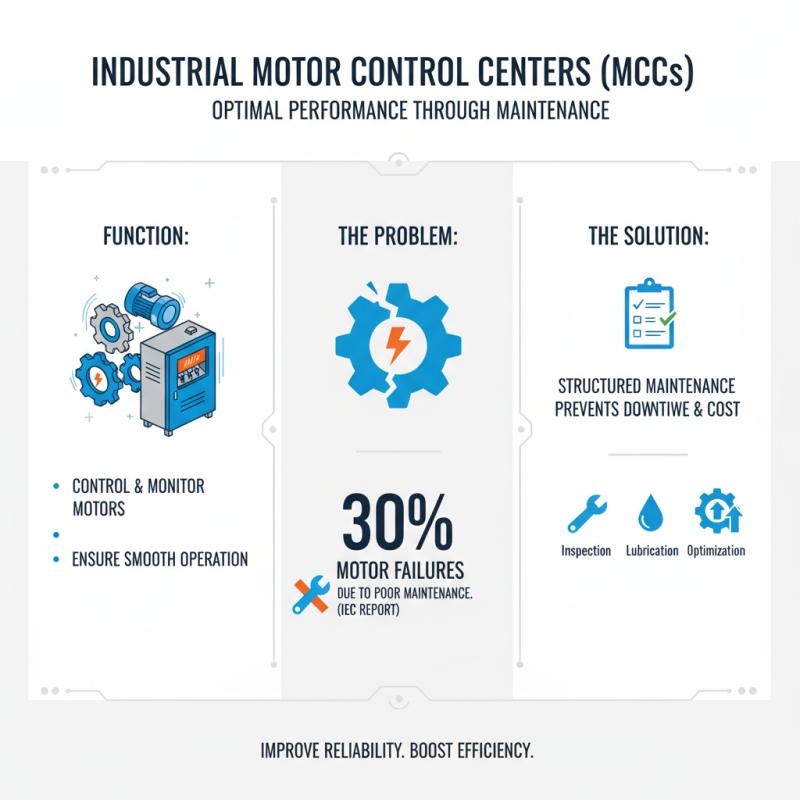

Maintenance Best Practices for Ensuring Optimal MCC Performance

Motor Control Centers (MCCs) play a critical role in industrial settings. They control and monitor electric motors, ensuring smooth operation. However, without proper maintenance, their efficiency can decline rapidly. According to a report by the International Electrotechnical Commission, about 30% of motor failures result from poor maintenance practices. This statistic highlights the need for a structured approach to maintenance.

Regular inspections are key. Checking for overheating, vibration, and unusual noise should be routine. Also, connections must be examined for corrosion or loosening. Studies show that roughly 20% of maintenance issues can be detected through visual inspections alone. Not all technicians prioritize this, which can lead to oversight. Neglecting these checks can eventually cause unplanned downtime.

Documentation of maintenance activities is often overlooked. Keeping records allows for tracking and analysis of common issues. It can flag recurring problems that may need a more profound investigation. A 2021 survey indicated that 40% of facilities do not maintain such records. This lack of organization can make it difficult to ensure optimal MCC performance over time. Regular training for staff can also be beneficial.

Related Posts

-

Understanding Motor Control Centers and Their Importance in Industry?

-

What is a Motor Control Center and How Does It Improve Efficiency in Industries

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Understanding the Future of Motors and Controls in Sustainable Technology