Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions

Recent studies highlight the critical role of frequency drives in revolutionizing energy efficiency within industrial automation. According to the International Energy Agency, variable frequency drives (VFDs) can enhance motor efficiency by up to 50%, significantly reducing energy costs and greenhouse gas emissions. As automation solutions continue to evolve, the integration of frequency drives becomes not just advantageous but essential for achieving sustainability goals. With energy consumption accounting for nearly 30% of global CO2 emissions, optimizing these systems is paramount. Leveraging advanced frequency drive technology not only streamlines operations but also provides measurable savings; reports suggest that industries implementing VFDs can reduce energy consumption by as much as 30-50%. By unlocking the power of frequency drives, businesses position themselves at the forefront of energy-efficient automation, paving the way for a greener and more profitable future.

Understanding Frequency Drives and Their Role in Automation

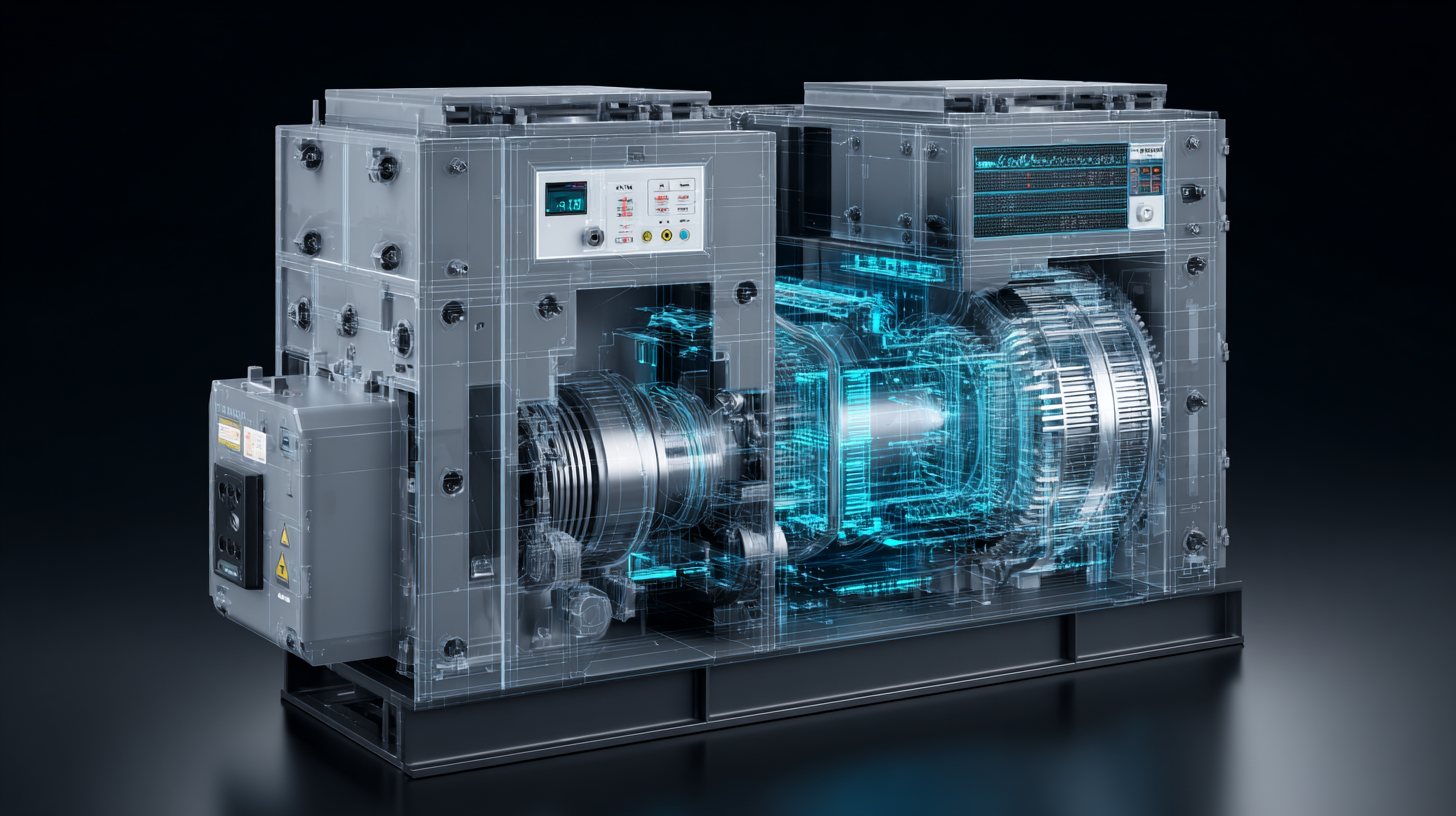

Frequency drives, also known as variable frequency drives (VFDs), play a crucial role in the automation landscape by optimizing the control of motor speed and torque. By adjusting the frequency and voltage supplied to electric motors, these drives enhance equipment efficiency and reduce energy consumption. This capability is particularly beneficial in industrial settings where machinery often operates at varying speeds. With the implementation of frequency drives, businesses can achieve significant energy savings while maintaining optimal performance across their operations.

In addition to improving energy efficiency, frequency drives contribute to better process control and equipment longevity. They allow for soft starting of motors, which minimizes mechanical stress and reduces maintenance costs associated with wear and tear. Moreover, their versatility enables integration into a wide range of automation systems, from simple pumps to complex manufacturing lines. As industries increasingly prioritize sustainability and cost-efficiency, understanding the functionalities and advantages of frequency drives becomes essential for driving innovation and achieving automation goals.

Key Benefits of Frequency Drives for Energy Efficiency

Frequency drives, also known as variable frequency drives (VFDs), have become essential in modern automation solutions, particularly in improving energy efficiency across various industrial applications. According to a report by the U.S. Department of Energy, implementing VFDs can lead to energy savings of up to 50% in motor-driven systems. This significant reduction in energy consumption not only lowers operational costs but also contributes to a greener environment by minimizing carbon footprints.

Frequency drives, also known as variable frequency drives (VFDs), have become essential in modern automation solutions, particularly in improving energy efficiency across various industrial applications. According to a report by the U.S. Department of Energy, implementing VFDs can lead to energy savings of up to 50% in motor-driven systems. This significant reduction in energy consumption not only lowers operational costs but also contributes to a greener environment by minimizing carbon footprints.

The benefits of frequency drives extend beyond mere energy savings. A study published by the International Energy Agency (IEA) highlighted that VFDs enhance the lifespan of motors and other equipment by allowing for smoother operation and reduced wear and tear. By optimizing the speed and torque of electric motors according to real-time demand, frequency drives prevent unnecessary energy expenditure and improve overall system reliability. This optimization can result in increased productivity and reduced maintenance costs, making VFDs a vital investment for companies aiming to streamline their operations while maintaining sustainability goals.

Integration of Frequency Drives in Modern Automation Systems

The integration of frequency drives into modern automation systems represents a pivotal shift in enhancing energy efficiency and operational effectiveness. Frequency drives, or variable frequency drives (VFDs), adjust the speed and torque of electric motors by varying the frequency and voltage of the power supplied. This capability allows for precise control over machinery, reducing energy consumption by adapting motor performance to the actual demand of the system. In industries where operational demands fluctuate, such as manufacturing and HVAC, VFDs enable significant energy savings and reduce wear and tear on equipment.

Moreover, the seamless incorporation of frequency drives into existing automation frameworks can streamline processes and enhance overall productivity. With advanced communication protocols, modern frequency drives can easily integrate with programmable logic controllers (PLCs) and other automation components, allowing for real-time monitoring and adjustment. This connectivity not only facilitates improved energy management but also enhances predictive maintenance by enabling data analytics. By harnessing the full potential of frequency drives, companies can optimize their operations, achieve sustainability goals, and remain competitive in a rapidly evolving market landscape.

Energy Efficiency of Automation Solutions with Frequency Drives

Best Practices for Implementing Frequency Drives in Industrial Applications

Implementing Variable Frequency Drives (VFDs) in industrial applications can significantly enhance energy efficiency and operational performance. With the growing focus on sustainability, the cement industry has embraced advanced technologies to reduce energy consumption, achieving notable reductions in operational costs and emissions. According to a recent market report, effective use of VFDs can contribute to up to 20-50% savings on energy bills in various industrial settings. This impactful reduction not only supports environmental goals but also aligns with stricter regulatory requirements in the industrial sector.

Tip: When integrating VFDs, ensure that proper training is provided to your workforce. Knowledgeable operators can maximize the benefits of these systems and identify potential issues before they escalate, thus maintaining continuous operational efficiency.

Additionally, it is crucial to prioritize cybersecurity measures when deploying VFDs, especially in applications tied to national security and public safety. Reports indicate that as the adoption of Industrial Internet of Things (IIoT) technologies expands, so does the vulnerability to cyberattacks. Implementing robust cybersecurity protocols can protect these systems from malicious threats, ensuring both operational integrity and safety.

Tip: Regularly update your cybersecurity strategies and conduct assessments to identify potential vulnerabilities within your automation systems.

Future Trends in Frequency Drive Technology and Energy Management

The future of frequency drive technology is set to revolutionize energy management across various sectors, significantly boosting efficiency and sustainability. According to recent insights, the North American Variable Frequency Drives (VFD) market is anticipated to grow substantially, driven by the rising adoption of VFDs in renewable energy applications. With the market projected to reach $25 billion by 2025, industries are increasingly recognizing the potential of frequency drives to reduce energy consumption and costs while enhancing process control.

Incorporating frequency drives not only optimizes energy usage but also aligns with sustainability goals and regulatory demands. As industries prioritize automation, the momentum for advanced drive technologies will likely accelerate. Notably, the integration of low-power AC drives into smart systems offers companies a means to significantly improve energy efficiency.

Tips:

1. Evaluate your current energy usage to identify areas where VFD technology could improve efficiency.

2. Stay informed about emerging trends in frequency drive technology to leverage advancements that can enhance operational productivity.

3. Consider participating in training programs to ensure your team is skilled in implementing and managing new drive technologies effectively.

Related Posts

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Top Strategies for Maximizing Efficiency with Electrical Switch Innovations

-

What are Electrical Breakers and Their Role in Electrical Safety Standards

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance