What is VFD Motor Control and How Does It Work?

VFD motor control is an essential technology in modern industry. It allows precise regulation of motor speed and torque. By adjusting the electrical frequency supplied to the motor, efficiency increases significantly. Imagine a factory where machines run smoothly, adapting to workload changes automatically.

This control method can lead to substantial energy savings. However, not all applications benefit equally from VFD motor control. Understanding where it works best is crucial for optimal performance. Users must evaluate their systems carefully. Challenges exist, such as initial costs and complexity.

The integration of VFD motor control can improve production processes. Yet, it requires ongoing maintenance and monitoring. Many operators may overlook this, leading to performance drops. Reflecting on these aspects enhances understanding and application of this powerful technology.

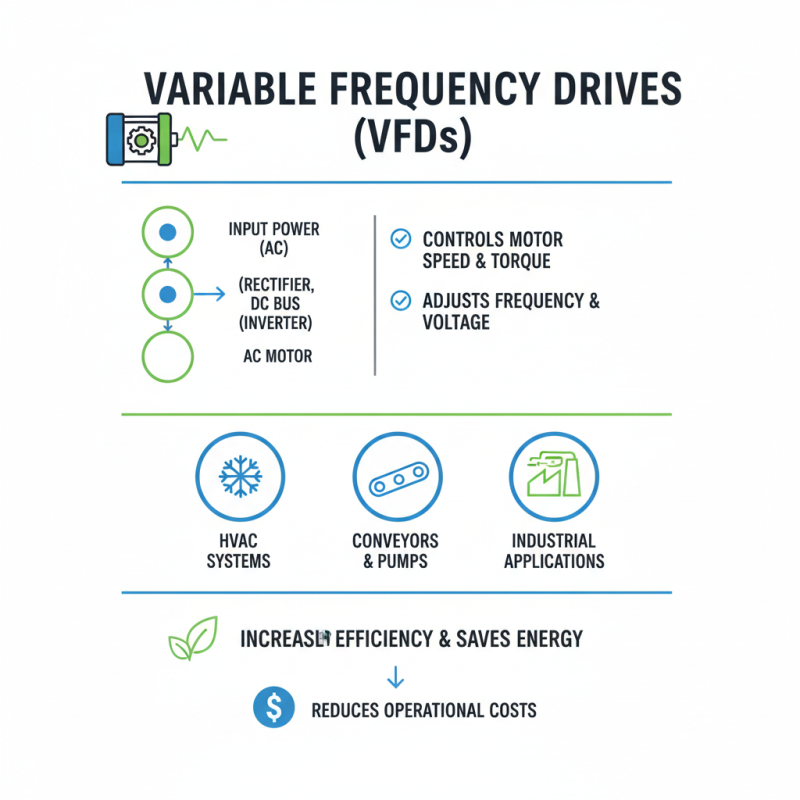

What is a Variable Frequency Drive (VFD)?

Variable Frequency Drives (VFDs) are essential for controlling motor speed and torque. They adjust the frequency and voltage sent to an electric motor. This process allows for precise control, enhancing efficiency. VFDs are commonly used in HVAC systems, conveyors, and pumps. They help reduce energy consumption and operational costs. By modifying the power supply, VFDs ensure optimal performance in various applications.

Using a VFD can lead to significant energy savings. Adjusting the speed of motors based on actual needs minimizes energy waste. However, implementing a VFD requires proper understanding. Incorrect setup can lead to inefficiencies or equipment damage. It’s crucial to analyze motor specifications and intended application beforehand.

Consider maintenance regularly. Over time, VFDs can develop issues like overheating or component wear. Monitoring the system can prevent unexpected failures. Keep an eye on temperature levels and vibrations. Small changes can indicate larger problems. Awareness is key for long-term efficiency.

Principles of VFD Motor Control Operation

Variable Frequency Drive (VFD) motor control is a method of regulating motor speed and torque. It achieves this by varying the frequency and voltage supplied to the motor. This method stands out for its efficiency and flexibility. By controlling motor speed, energy consumption can be reduced. This is crucial in many industrial applications.

The principles behind VFD operation revolve around converting electrical energy. The VFD first takes in AC power, rectifies it to DC, and then inverts it back to AC at the desired frequency. This process allows for precise control over motor operation. Sensors often feed data back to the drive. However, if the sensors fail, the system may not operate as intended.

VFDs can lead to complications too. Issues like harmonic distortion can arise, impacting nearby equipment. Regular maintenance is essential to prevent these problems. While modern VFDs come with advanced features, their complexity can overwhelm users. Lack of training can lead to improper setups. Understanding these principles is essential for effective motor control.

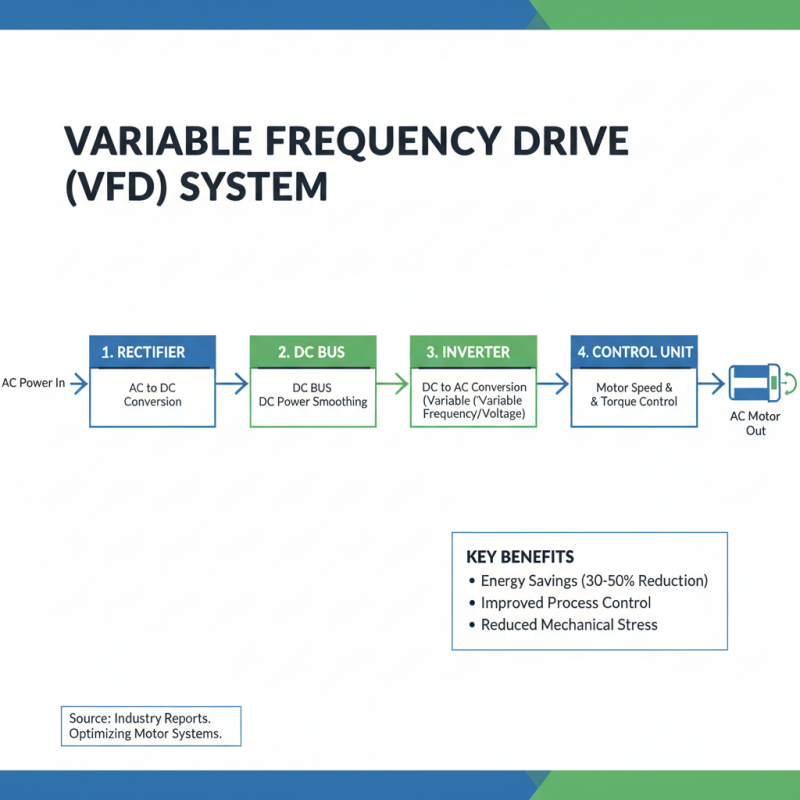

Components of a VFD System

A Variable Frequency Drive (VFD) system comprises several key components. These are vital for controlling motor speed and torque. The main elements include the rectifier, DC bus, inverter, and control unit. The rectifier converts AC to DC power. This process is essential for ensuring a stable power supply to the motor. According to industry reports, around 30-50% of energy is wasted in motor systems without VFDs.

The DC bus stores the converted power. It smoothens the voltage and ensures a consistent supply. The inverter then converts the DC back to AC with variable frequency. This change in frequency allows precise control over motor speed. Studies indicate that VFDs can improve energy savings by up to 60%. These systems are especially efficient in applications with variable load conditions.

The control unit is the brain of the VFD. It manages the operation based on user inputs and feedback from the motor. However, there's often a knowledge gap among operators regarding optimal control settings. Misconfigurations can lead to inefficiency or even equipment damage. Continuous training and improvements in user understanding are necessary for maximizing the benefits of a VFD system.

Benefits of Using VFDs in Motor Control

Variable Frequency Drives (VFDs) offer several advantages in motor control. They enhance energy efficiency, which is vital in today's industrial landscape. According to a report by the U.S. Department of Energy, VFDs can reduce energy consumption by up to 50%. This decrease directly translates to cost savings for facilities.

Additionally, VFDs improve equipment lifespan. By controlling motor speed smoothly, they prevent mechanical wear. A smoother operation leads to less vibration and reduced maintenance. However, some facilities struggle to implement these technologies effectively. Users may face initial setup challenges that can overshadow these benefits.

Another key benefit is precise process control. VFDs enable better automation and control over production parameters. At the same time, businesses often overlook the need for proper training. Ensuring that employees understand how to utilize VFD technology can maximize operational efficiency. Failure to address this can lead to underwhelming results in productivity.

What is VFD Motor Control and How Does It Work? - Benefits of Using VFDs in Motor Control

| Dimension | Description | Benefits |

|---|---|---|

| Speed Control | VFDs allow precise control of motor speed, enabling optimal performance for different applications. | Increased energy efficiency and reduced wear on motor components. |

| Torque Control | They can regulate the torque delivered by the motor, enhancing the operational capacity. | Improved process control and enhanced performance of machinery. |

| Soft Start | VFDs can start motors slowly and gradually increase speed, reducing mechanical stress. | Minimized impact on electrical systems and extended motor life. |

| Energy Savings | VFDs adjust power supply to motors based on demand, leading to significant energy savings. | Cost reduction in energy bills and lower carbon footprint. |

| Diagnostics | Many VFDs come with built-in diagnostic tools to monitor performance and detect issues. | Easier maintenance and quicker identification of problems. |

Applications of VFDs in Various Industries

Variable Frequency Drives (VFDs) play a crucial role in various industries by controlling the speed and torque of electric motors. These drives are widely used in HVAC systems, pumps, and conveyor belts. In HVAC systems, VFDs help in maintaining optimal air flow, enhancing energy efficiency. This not only reduces utility costs but also minimizes wear on motors.

In the water treatment industry, VFDs regulate pump speeds based on demand. This leads to better control of water flow and pressure. It can also result in significant energy savings. In manufacturing, VFDs allow for precise control of machinery, which improves production processes. However, not every application of VFDs is flawless. Improper programming may lead to inefficiencies or equipment stress. Therefore, it is essential to regularly assess the performance of VFDs in such settings.

In agriculture, VFDs assist in irrigation by controlling water pumps effectively. This helps in optimizing resource use. Yet, budget constraints may prevent some farmers from investing in this technology. The awareness of VFD technology remains limited in certain regions. Understanding its potential benefits can help industries make informed decisions. VFDs offer numerous applications, but ongoing training is critical for success.

Applications of VFDs in Various Industries

Related Posts

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

2025 Top 5 Motor Soft Starter Options for Efficient Energy Management

-

10 Essential Tips for Choosing the Right Soft Start Motor Starter

-

Top 7 Electric Motor Starters for Enhanced Efficiency: Boost Your System’s Performance by 25%!

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications

-

Understanding the Future of Motors and Controls in Sustainable Technology