Why Choose a Ball Screw for Sale for Your Projects?

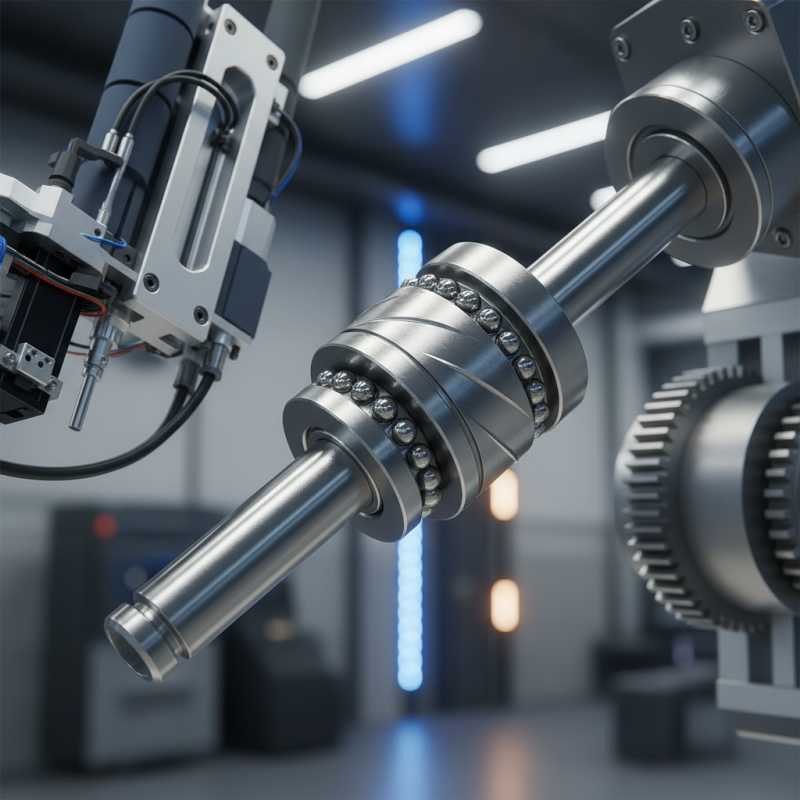

When considering efficiency and precision in mechanical applications, a ball screw for sale often stands out as an optimal choice. Research indicates that ball screws can achieve mechanical efficiency rates as high as 90%, significantly outperforming traditional screw mechanisms. This is crucial in high-speed applications where performance directly affects productivity.

In industries such as automation, robotics, and aerospace, reliable motion control is essential. A ball screw offers reduced friction and heat generation. This enhances its lifespan and reliability. Investing in a ball screw for sale can be seen as a proactive approach to minimize downtime through its durable design.

However, buyers must carefully assess their needs. Not all ball screws are created equal. Variability in load capacity, tolerances, and materials can significantly impact performance. It's essential to choose the right specifications tailored to the project requirements. Making an informed choice can lead to greater operational efficiency and reduced costs in the long run, reflecting the complexity of the selection process.

Benefits of Using Ball Screws in Mechanical Projects

Ball screws are a popular choice for many mechanical projects. They offer precision and efficiency. A key advantage is reduced friction. This feature increases performance, allowing for smoother motion. Engineers often appreciate precision in their designs. Ball screws can provide this, making them essential.

Using ball screws can also enhance load capacity. They minimize wear over time. This improves longevity in mechanical systems. Precise movements are critical in applications like automation. In these scenarios, ball screws excel by ensuring accuracy. Their ability to handle high loads while maintaining precision is impressive.

However, not all projects require ball screws. Some may find them costly or complex for simple tasks. It's vital to assess the project needs carefully. Choosing the right component is crucial for success. A thoughtful balance between cost and performance can lead to better results. Ignoring this may lead to inefficiencies or wasted resources.

Benefits of Using Ball Screws in Mechanical Projects

Differences Between Ball Screws and Traditional Lead Screws

Ball screws and traditional lead screws serve similar purposes but achieve them differently. Ball screws use ball bearings to reduce friction. This results in higher efficiency, particularly for high-speed applications. Research shows that ball screws can have an efficiency of up to 90%. In comparison, traditional lead screws typically have an efficiency ranging from 30% to 70%. This lower efficiency can be a significant drawback for machine designers aiming for precise and effective movement.

Maintenance is another area where ball screws outperform lead screws. Ball screws often have a longer lifespan, a factor backed by industry studies. The lifespan can extend beyond 100,000 cycles under optimal conditions. Conversely, lead screws may require more frequent replacements due to wear. However, the initial cost of ball screws is usually higher. This can deter some projects from using them. In the long run, the investment can pay off.

Moreover, ball screws offer better load-carrying capabilities. They can handle larger loads with less backlash, making them ideal for applications requiring reliable performance. Nevertheless, the installation complexity of ball screws may increase project timelines. This challenges engineers to weigh the pros and cons carefully, considering both performance and budget constraints.

Applications of Ball Screws in Various Industries

Ball screws are essential components in many industries. They provide high precision and efficiency in linear motion. For example, in manufacturing, ball screws enable accurate positioning of machines. They help improve production speed and product quality. This is crucial when machining parts that require tight tolerances.

In the automation sector, ball screws play a vital role. They are used in robotic arms and conveyors. These systems rely on precise movement and control. In the medical field, ball screws assist in the operation of surgical equipment. Their reliability can make a difference during critical procedures.

However, not all applications may require ball screws. Some projects might not benefit from the added complexity they bring. It’s important to assess your specific needs. Evaluate both efficiency and cost. A hasty decision can lead to unnecessary expenses. Reflect on whether simpler solutions might suffice.

Factors to Consider When Selecting Ball Screws for Your Needs

When selecting ball screws for your projects, several critical factors come into play. Precision is paramount. According to industry reports, ball screws can achieve an accuracy level of 10 microns. This precision is essential for applications requiring exact movements, like CNC machinery. You must evaluate the expected load and duty cycle. Heavy loads may need larger diameter screws to handle stress without failure.

It's also crucial to consider the nut configuration. There are various options, including preloaded and circulating types. Preloaded nuts can enhance stiffness but may introduce backlash. Often, engineers face dilemmas in balancing performance and reliability. The choice of materials is another aspect to reflect upon. High-carbon steel and stainless steel are common. They provide durability but come with different cost implications.

Finally, there's efficiency to think about. Ball screws operate with a higher efficiency rate than lead screws, often above 90%. However, they may need regular maintenance to keep that efficiency. Ignoring maintenance schedules can lead to decreased performance. Evaluating these factors early can prevent complications later. Balancing all elements presents a challenge, but making informed choices will yield long-term benefits.

Cost-Effectiveness of Ball Screws for Long-Term Projects

Ball screws have gained popularity in various engineering and manufacturing projects. One key reason is their cost-effectiveness for long-term applications. Unlike traditional lead screws, ball screws offer increased efficiency, thanks to their rolling element design. This means less friction and a longer lifespan. Companies can reduce maintenance costs significantly by using ball screws.

Investing in ball screws might seem high upfront, but you'll save in the long run. Their durability can lead to fewer replacements. Additionally, ball screws operate quietly and smoothly, enhancing overall productivity. However, it's crucial to choose the right specifications. Misjudging load capacities can lead to failures or unnecessary wear.

It's not all smooth sailing. Some users struggle with installation. Ensuring proper alignment is essential for optimal function. Regular maintenance checks can remedy minor issues before they escalate. Moreover, assessing the project requirements is vital. Not every application benefits from ball screws. Careful consideration and testing should guide your choice.